A steel arch beam assembly device for hard rock boring machine

A technology of a hard rock roadheader and an assembly device, which is applied to shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of high replacement ring gear cost, gear pitting, wear, etc., and achieves low maintenance cost, convenient replacement and high price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

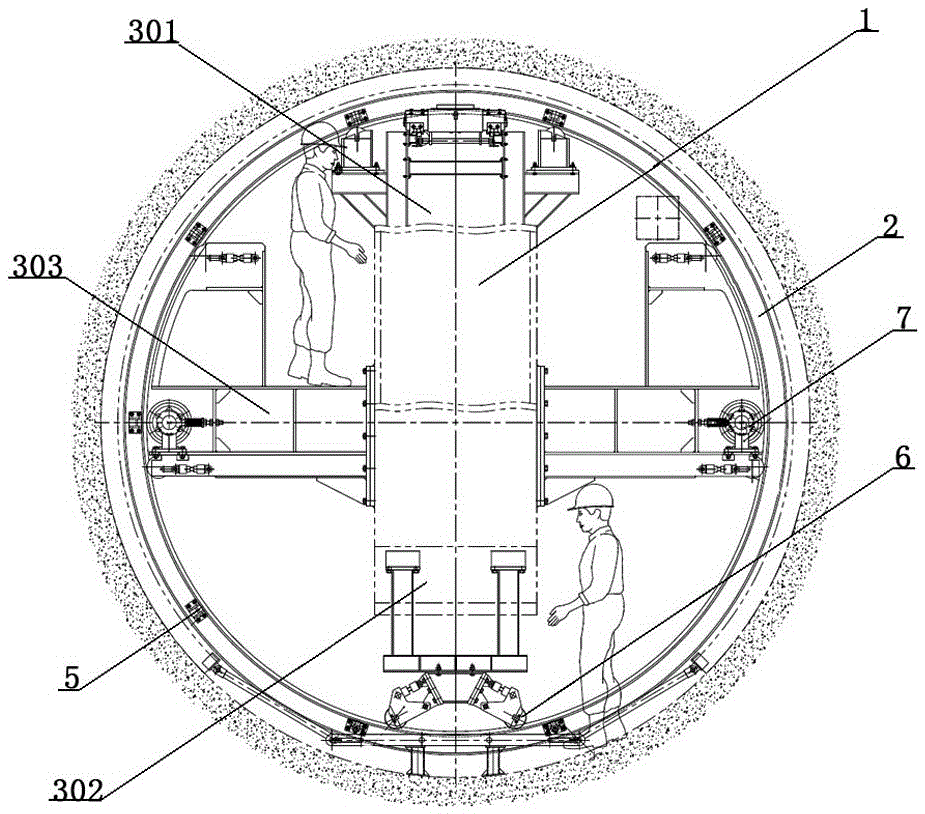

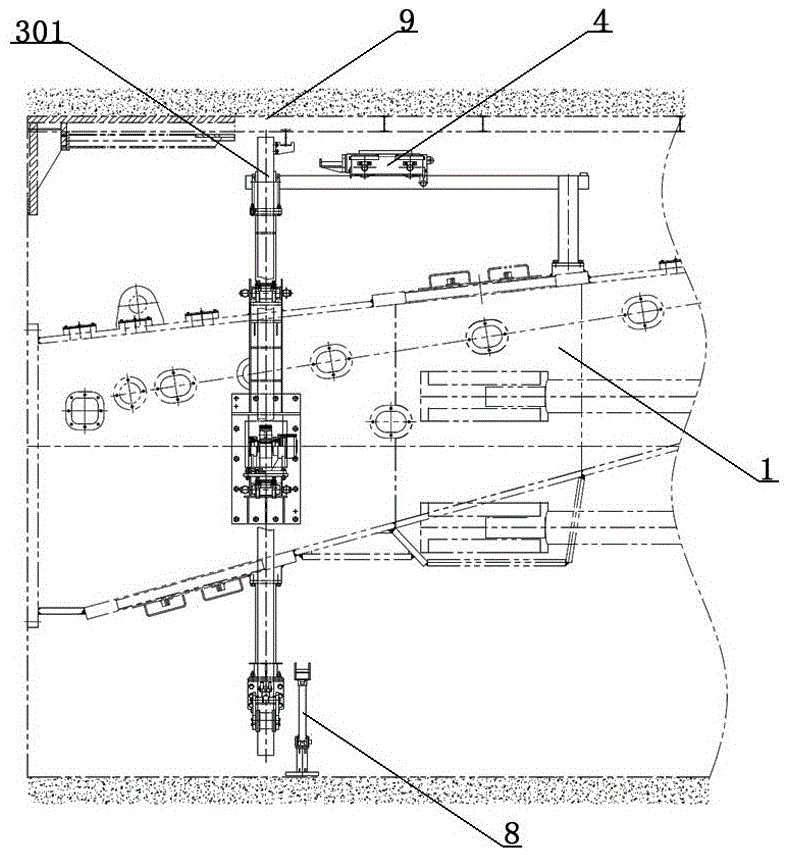

[0015] As shown in the figure: a steel arch beam assembly device for hard rock roadheader, the assembly device is fixed on the girder 1 of the hard rock roadheader, the assembly device is mainly composed of swivel 2, swivel support, swivel The driving mechanism 7, the jacking trolley 4 and the spreading mechanism 8 are composed. In this embodiment, eight ring beam supports 5 are scattered on the same side of the swivel 2, and two adjacent ring beam supports 5 have clamping device, the clamping device can realize the clamping of the ring beam 9, and the 270° ring beam 9 is divided into five sections. Tighten it, then turn the swivel, install the other four sections of ring beam 9 in sequence, and connect each section with bolts. After the splicing is completed, the 270° ring beam 9 is symmetrically placed on the ring beam support 5, and the clamping is loosened at this time. device. The swivel support is provided with 8 supporting rollers 6, and the upper support 301, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com