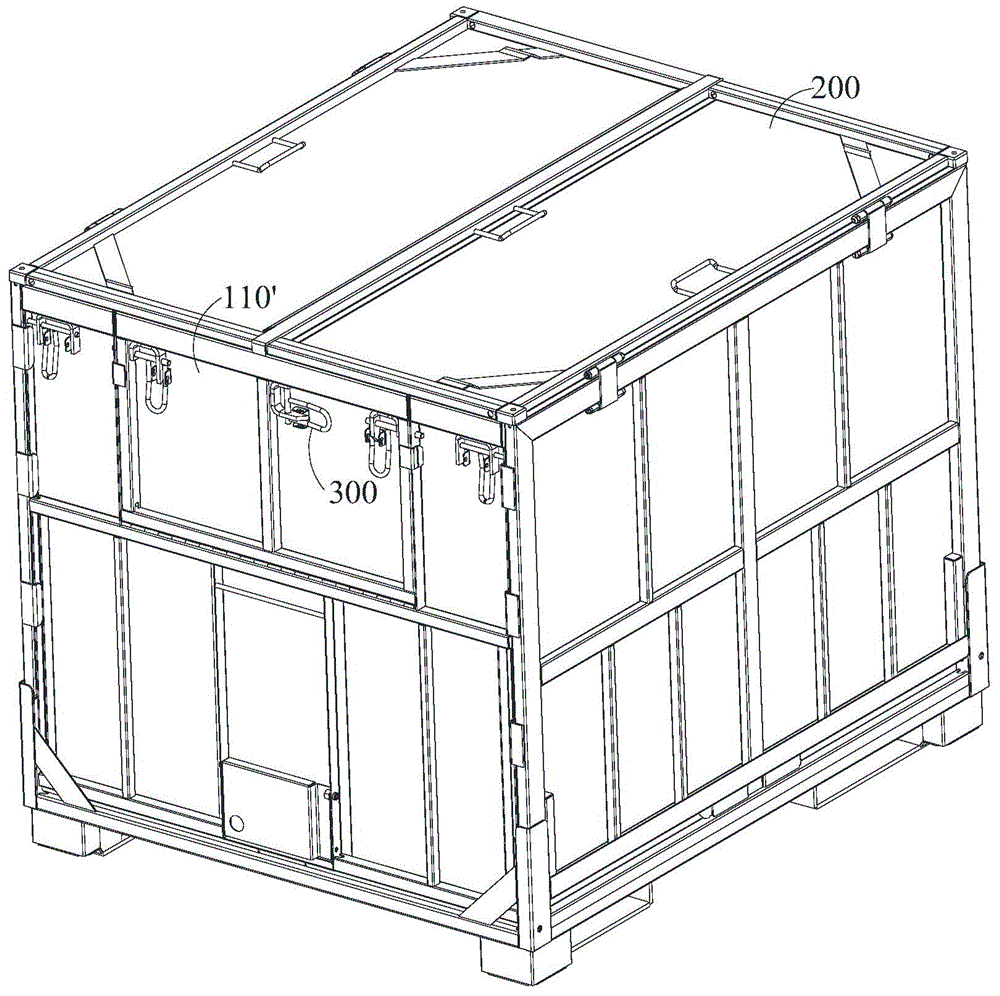

Lock and tray box

A pallet box and lock technology, which is applied in the direction of locking equipment, rigid containers, containers, etc., can solve problems such as damage to the side wall parts of the hook lock handle, and achieve the effects of low cost, convenient operation and simple lock structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

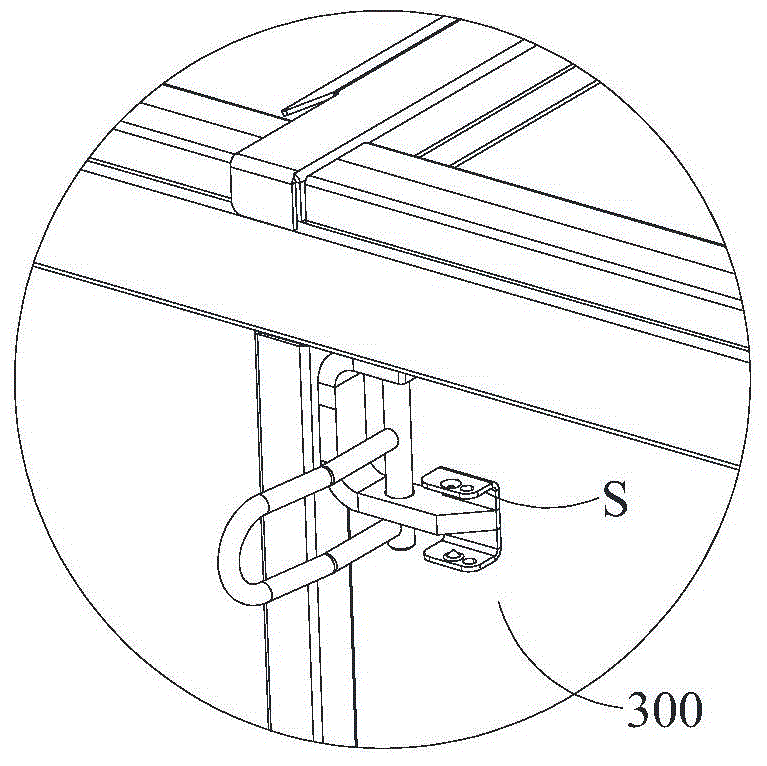

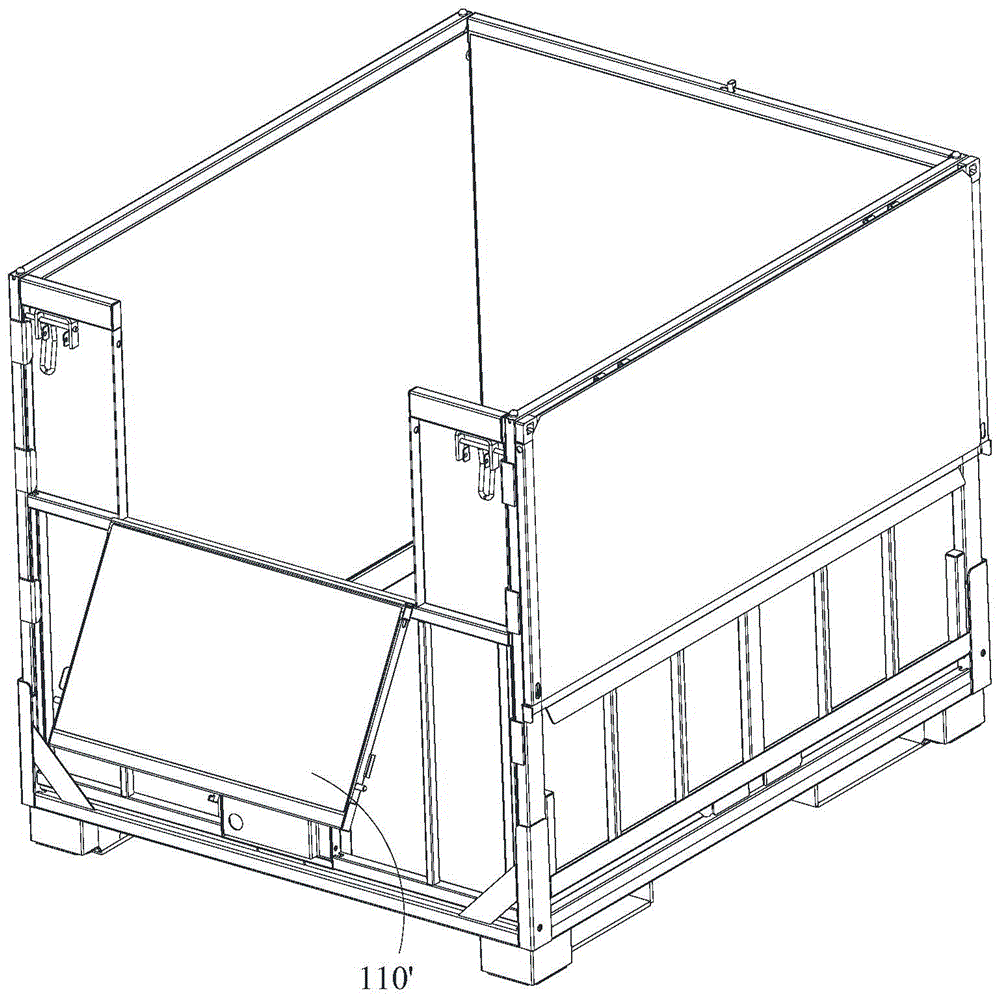

[0048] refer to Figure 9-Figure 11, the lock 10 of the present embodiment comprises a lock plate 11, a pin shaft 12 and an elastic member 14. The upper end of the lock plate 11 has a hook portion 111, and a perforation 112 is provided below the hook portion 111, and one end of the pin shaft 12 passes through the perforation 112 and is fixed. on the end wall 100. The elastic member 14 is sleeved on the outer periphery of the pin shaft 12 and pressed on the locking plate 11 . The lock plate 11 rotates around the pin shaft 12 to be in Figure 10 Locked state as shown or Figure 18 In the open state shown, in the locked state, the hook portion 111 is locked with the top cover 200; The lock plate 11 is held in a locked state or an open state.

[0049] Since the lock does not protrude from the outer contour of the end wall in the opened state, it can avoid damage to the parts when the end wall is opened or folded. Moreover, the locking plate is kept in the locked state or the ...

no. 2 example

[0059] The difference between this embodiment and the first embodiment is that, if Figure 20 As shown, the inner edge S2 of the second locking hole 130 is provided with a vertical plate 140 that enters the interior of the second connecting beam 110 and extends to the bottom surface of the second connecting beam 110, and defines the space between the vertical plate 140 and the outer edge S3 of the locking plate 11. The rotation space allows the lock plate 11 to rotate freely in the rotation space without being interfered by the inner edge S2 of the second lock hole 130 .

no. 3 example

[0061] The difference between this embodiment and the first embodiment is that, if Figure 21 , 22 As shown, on the side of the lock plate 11 facing the cover plate 120, a protrusion 114 is protruded from the upper end of the lock plate 11. The protrusion 114 contacts the outer surface of the inner wall of the second connecting beam 110, and the protrusion 114 The height is greater than or equal to the distance d between the outer surface of the inner wall of the second connecting beam and the inner edge of the second locking hole, so that there is a distance between the locking plate 11 and the inner side of the second connecting beam 110, and will not be in contact with the second connecting beam 110 during rotation. The inner edges S2 of the two locking holes 130 interfere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com