Stacking machine goods carrying table with balance capable of being adjusted finely

A technology for loading platforms and stackers, which is applied in the direction of lifting devices, etc., can solve problems such as levelness and horizontal spacing errors, and affect the use accuracy of stackers, so as to reduce processing and production requirements, save costs, and achieve high adjustment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

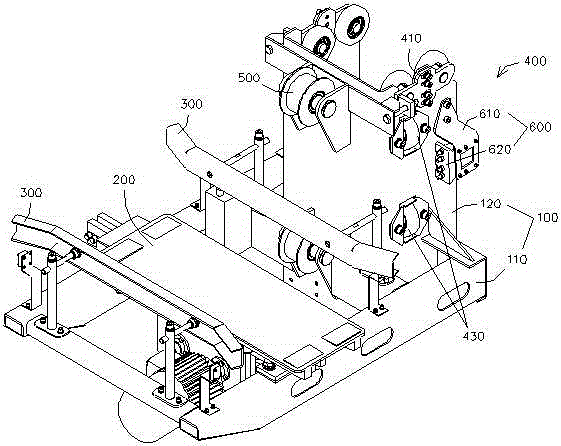

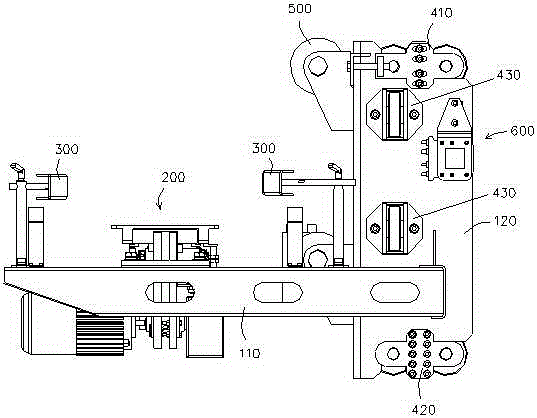

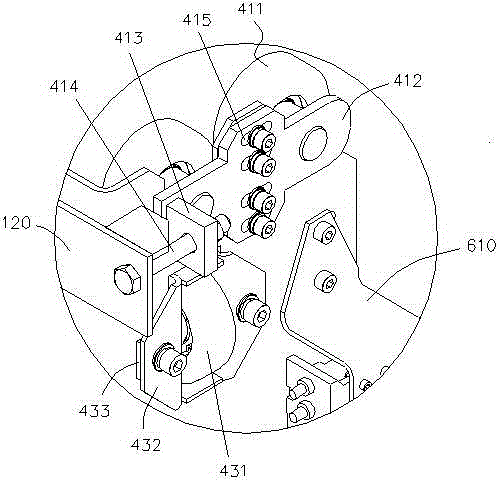

[0017] Such as figure 1 with 2 As shown, the loading platform includes a loading platform main body 100 , a fork mechanism 200 , a guiding and limiting bar 300 , a guiding mechanism 400 , an optical wheel set 500 and a detection device 600 .

[0018] The main body 100 of the loading platform is composed of a fixedly connected horizontal frame 110 and a vertical frame 120. The horizontal frame and the vertical frame are the main parts of the loading platform and are also the main components of the load. Other parts of the loading platform are installed on the Therefore, the design of the horizontal frame and the vertical frame has been designed based on experience and engineering mechanics, and the thickness of each part has been adjusted through SolidWorks finite element analysis. , scientifically solve the bearing problem of this part in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com