Super-quick-drying alkyd primer coating and preparation method therefor

An alkyd and primer technology, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of poor anti-sagging performance, anti-skinning, long drying time, and limited practical application range, etc., to achieve excellent and fast drying Performance, the effect of improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

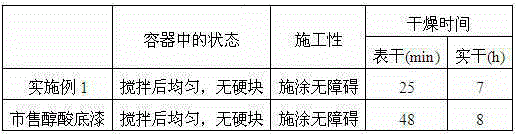

Examples

Embodiment 1

[0018] Raw material ratio: 30 parts by weight of sorbitol modified linseed oil medium oil alkyd resin, 20 parts by weight of TDI modified soybean oil alkyd resin, 0.2 parts by weight of drier (cobalt drier and rare earth drier each 0.1 wt. ), 2 parts by weight of coloring pigment, 1 part by weight of antirust pigment, 8 parts by weight of talcum powder of 1200-1300 mesh of inorganic filler, 15 parts by weight of low boiling point organic solvent sherwood oil, 0.5 part by weight of dispersant, and 0.1 part by weight of thickener , 0.1 parts by weight of polyether modified polydimethylsiloxane defoamer and 0.2 parts by weight of leveling agent. The preparation steps are as follows:

[0019] (1) Add sorbitol-modified linseed oil mid-oil alkyd resin, TDI-modified soybean oil alkyd resin, dispersant and some low-boiling organic solvents into the dispersion container, and stir evenly at 1000 rpm;

[0020] (2) Reduce the speed to 500rpm, add coloring pigments, anti-rust pigments, in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap