Clothes dryer drying program optimization method realizing energy saving time saving effect

A drying program and technology for clothes dryers, which are applied in household clothes dryers, washing devices, textiles and papermaking, etc., can solve problems such as increased production costs, inability to use interchangeably, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

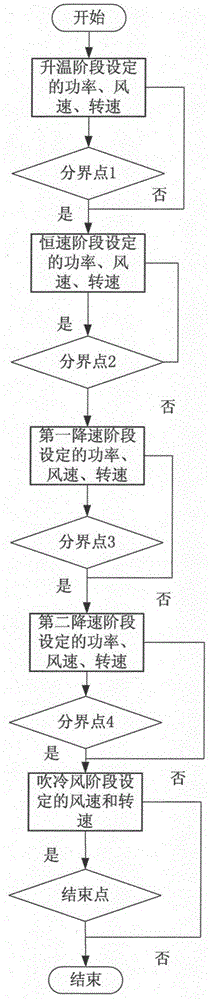

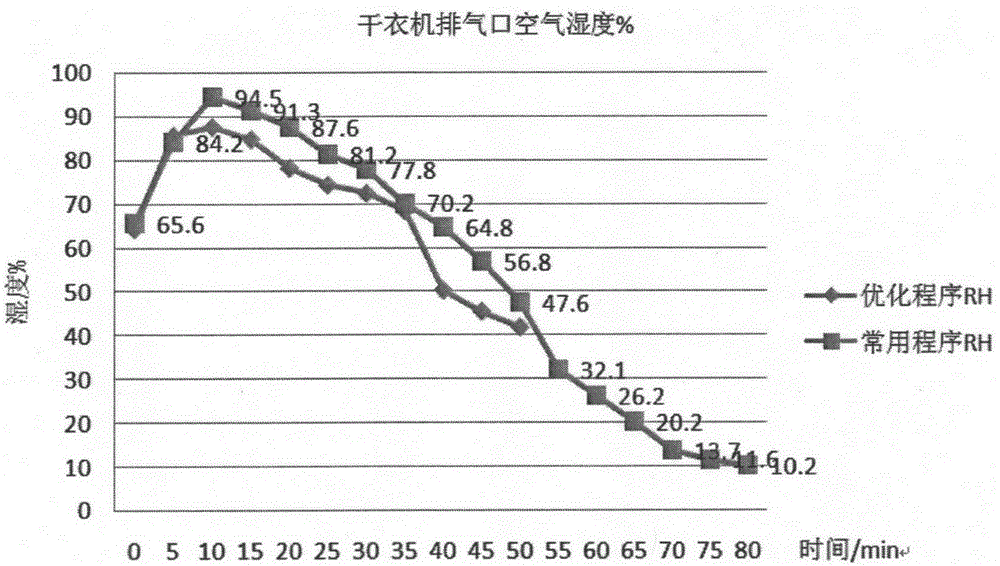

[0040] The specific example is as follows: before drying, the experimental load is washed in the model TG90-1416MPDG washing and drying machine before drying. Adjusted to 70% (± 2%). Then lay it flat and put it into Haier's model GNZ10-977 thermoelectric direct discharge clothes dryer for drying treatment. The specific drying program is: the cut-off point 1 is set to 8 minutes after the start of the drying program, and the cut-off point is not reached At point 1, the dryer will execute the combination of drying parameters in the heating stage, that is, the power is 4500W, the wind speed is 5.8m / s, and the rotation speed is 42-25rpm; Perform the drying parameter combination of the constant speed drying stage, that is, the power is 4500W, the wind speed is 11.0m / s, and the speed is 45-47rpm; when the cut-off point 2 (air humidity at the exhaust port is 78%) is not reached, the dryer will continue to perform constant speed drying. The combination of drying parameters set in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com