A Nonlinear Rail-Type Particle Damper

A kind of particle damper, non-linear technology, applied to bridge parts, building components, bridges, etc., can solve the problems of limited collision energy consumption and limited particle movement ability, and achieve improved energy consumption efficiency, good reset function and automatic limit Position ability, durability and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

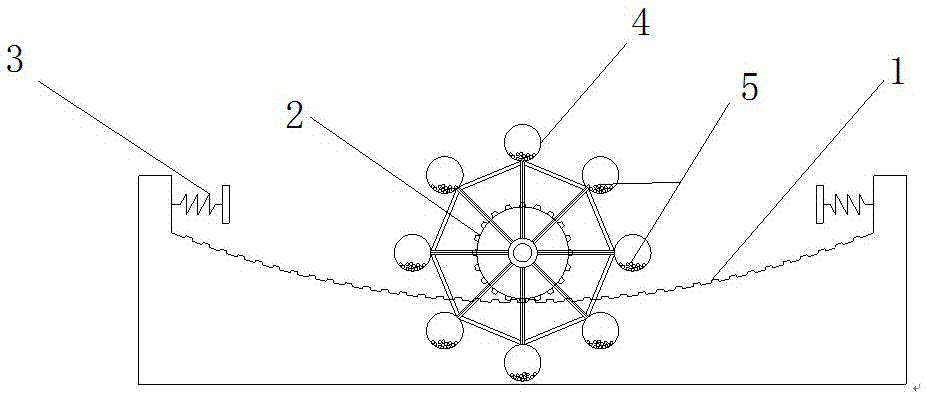

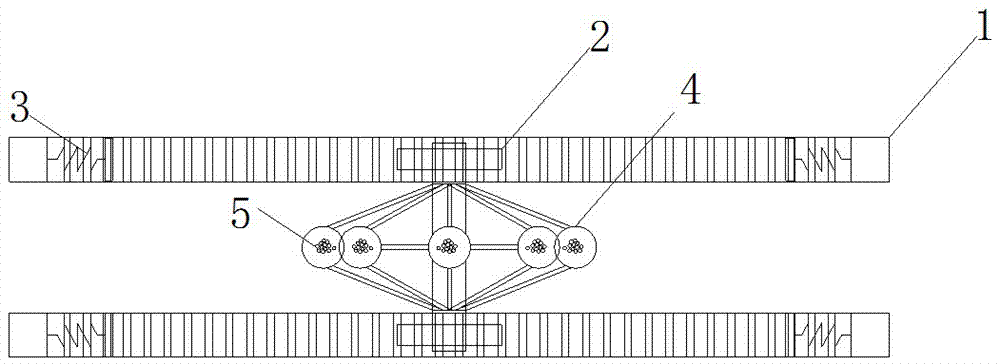

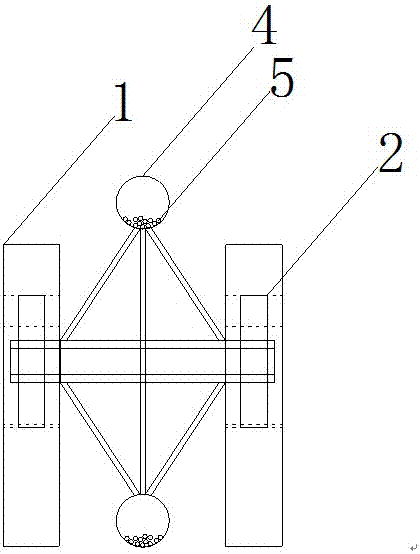

[0020] Embodiment 1: as figure 1 Shown is an embodiment of a nonlinear track-type particle damper of the present invention, which mainly includes an outer track 1 , rollers 2 , buffer elements 3 , damper cavity unit 4 and particle groups 5 .

[0021] The outer track 1 is designed with a non-linear curved surface and is connected to the main system through a fixing device. The surface is covered with cushioning materials. The roller 2 is connected to the central rotating shaft and placed on the outer track 1. The rotating shafts are connected, the damper cavity unit 4 is a cuboid or spherical structure, and a layer of particle groups 5 is arranged inside each damper cavity unit 4, the particle group 5 is composed of round or irregularly shaped particles, and the material can be metal Any one or more of , concrete, glass or ceramics. The system combines the advantages of the mass damper and the particle damper, and transfers and dissipates the energy of the structure through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com