Round nut locking structure

A round nut and anti-loosening technology, which is applied in the direction of nuts, screws, bolts, etc., can solve the problems of the stop plate and round nut coming out, the force of the retaining ring, and abnormal contact, so as to eliminate the axial gap and avoid abnormal force Produce and ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

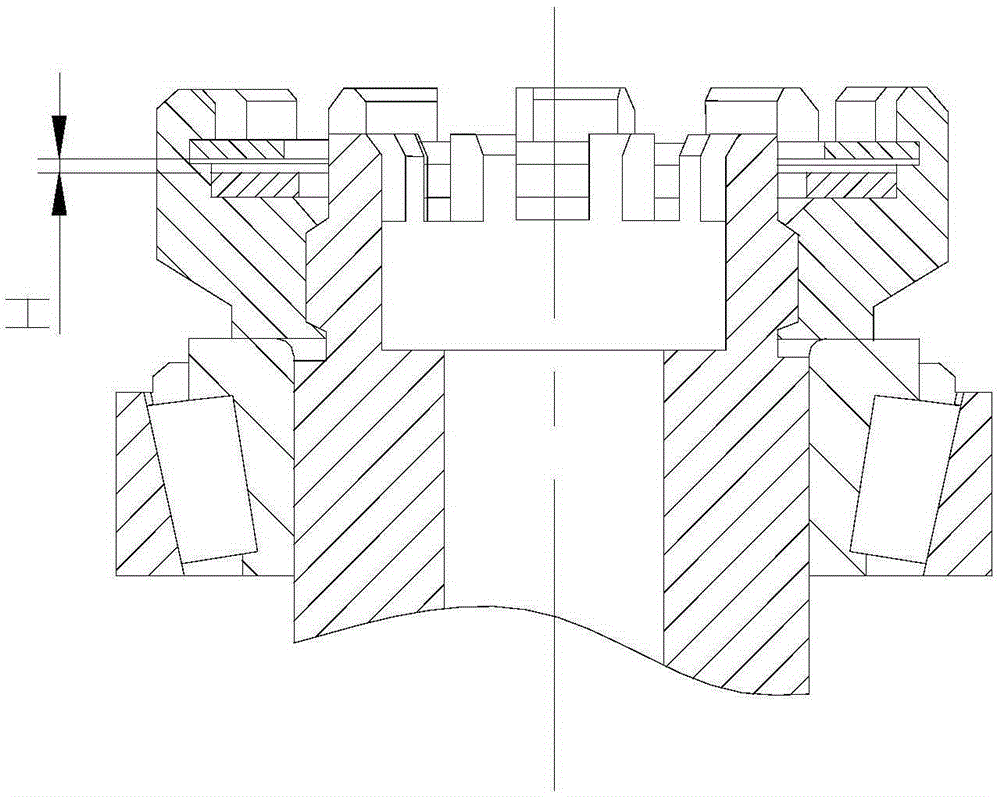

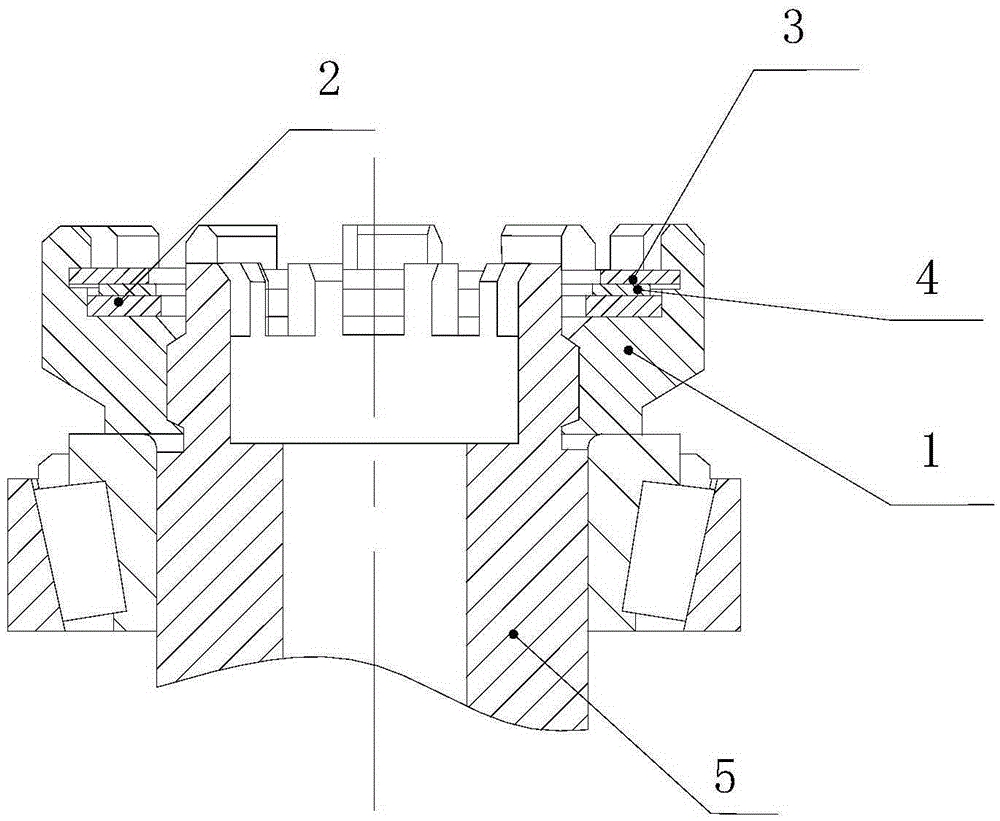

[0008] As shown in the figure, the round nut anti-loosening structure includes a round nut 1, a stop plate 2, a retaining ring 3, and a wave spring 4. The stop plate 2 is provided with inner and outer claw structures, and the round nut 1 is installed on the shaft. 5, both the inner hole of the round nut 1 and the end of the shaft 5 are provided with grooves, the inner claws on the stop plate 2 are stuck in the grooves at the end of the shaft 5, and the outer claws are stuck in the grooves in the inner hole of the round nut 1, The retaining ring 3 is installed in the groove on the inner hole of the round nut 1 to play the role of axially fixing the stop plate; the wave spring 4 is arranged between the stop plate 2 and the retaining ring 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com