Single-action shifting fork type pneumatic actuator

A pneumatic actuator, single-acting technology, applied in the direction of engine components, valve operation/release devices, valve details, etc., can solve the problems of inconvenient operation, laborious manual adjustment, etc., to prolong service life, reduce radial wear, reduce Effect of cylinder power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

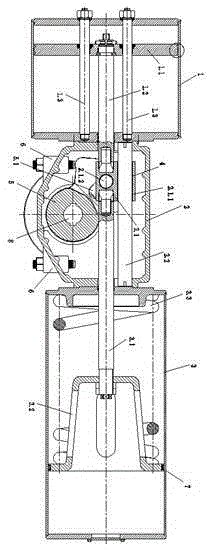

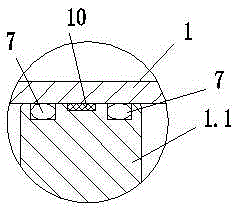

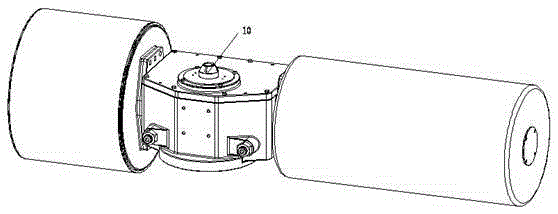

[0013] Example 1: A single-acting shift fork type pneumatic actuator, including a left cylinder 1, a middle shift fork cylinder 2 and a right spring cylinder 3, which are connected in a sealed manner. The cylinder 1 includes a piston 1.1, and the center of the piston 1.1 is provided Piston rod 1.2, two sides of the piston rod 1.2 are provided with guide posts 1.3, the left end of the piston rod 1.2 is consolidated with the center of the piston 1.1, the right end extends into the fork cylinder 2 to connect to one end of the movable block 2.1, and the other end of the movable block 2.1 is connected to the spring rod 3.1 At the left end, the right end of the spring rod 3.1 extends into the spring cylinder 3 to connect with a spring seat 3.2 that can slide back and forth along the inner wall of the spring cylinder 3. One end of the spring 3.3 is sleeved on the spring seat 3.2 and the other end is pressed against the left end of the spring cylinder 3. The block 2.1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com