Comprehensive and automatic construction material field material measurement system and method

An automatic measurement and material technology, applied in measurement devices, instruments, etc., can solve the problems of being easily interfered by human factors, low measurement accuracy, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

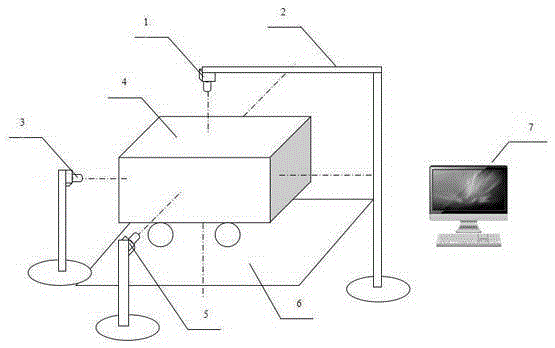

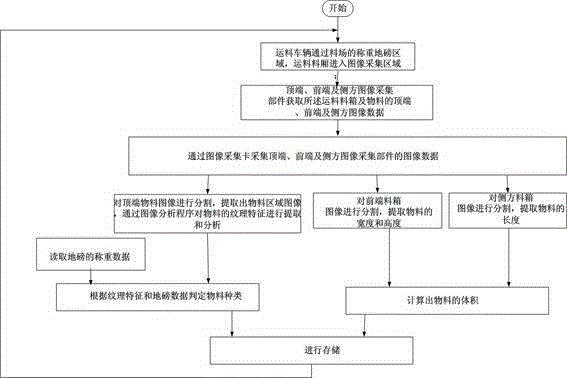

[0033] Such as figure 1 Shown, according to a kind of comprehensive automatic measurement system of construction stockyard material of the present invention, comprise a material delivery box 4 loaded on the delivery vehicle, a weighing platform 6 and a computer 7 for measuring material weight, its It is characterized in that it also includes a top image acquisition part 1, a front end image acquisition part 5, and a side image acquisition part 3 respectively fixed on the bracket 2;

[0034] The top image acquisition part 1 is installed above the weighing platform 6, and is used to obtain the top image data of the transport bin 4 and the material;

[0035] The front-end image acquisition part 5 is installed on the front end of the weighing platform 6 for obtaining the front-view image of the material box 4;

[0036] The side image acquisition part 3 is installed on the side of the weighing platform 6, for obtaining the side view image of the material box 4;

[0037] The compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com