Automatic assembly line for storage battery plate package machine

An automatic assembly line and plate-packing machine technology, applied in battery assembly, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of human health injury, slow finishing, low processing efficiency, etc., and achieve a high degree of automation , The effect of uniformity is good, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

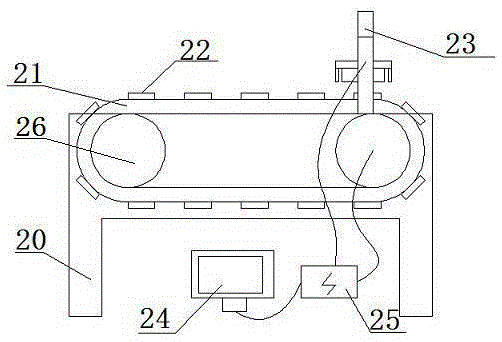

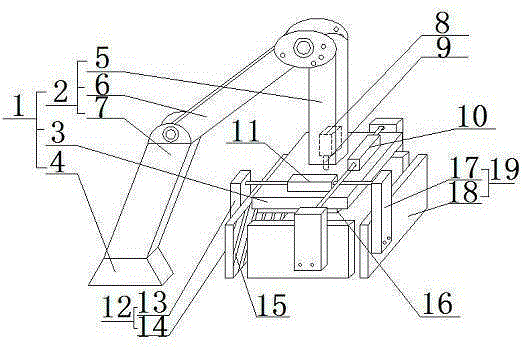

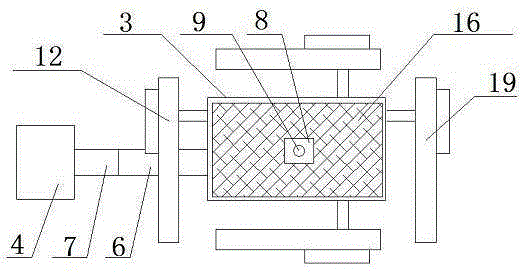

[0018] An automatic assembly line for a battery pack machine, including a machine tool 20, an extreme group arrangement mechanism 23, a motor 25 and a central control computer 24, wherein the machine tool 20 is provided with an endless chain 21, and the endless chain 21 is provided with a sprocket 26, the surface of the endless chain 21 is provided with a number of trays 22, the pole group arrangement mechanism 23 is arranged at the end of the machine bed 20, the pole group arrangement mechanism includes a frame 1, and the frame 1 includes a machine base 4 and a bracket arm 2 and a horizontal frame 3, one end of the support arm 2 is arranged in the base 4, and the other end is connected with the horizontal frame 3, the support arm 2 includes a support arm 7, a driving arm 6 and a vertical arm 5, and the driving arm 6 is rotatably connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com