Connection assembly for connecting lead with printed board and fixing sleeve of connection assembly

A technology for connecting components and printed boards, applied in the direction of connection, fixed connection, circuit, etc., can solve problems such as shielding layer processing, conductive pins are easy to loose, signal transmission failure, etc., to ensure the quality of signal transmission and prevent stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

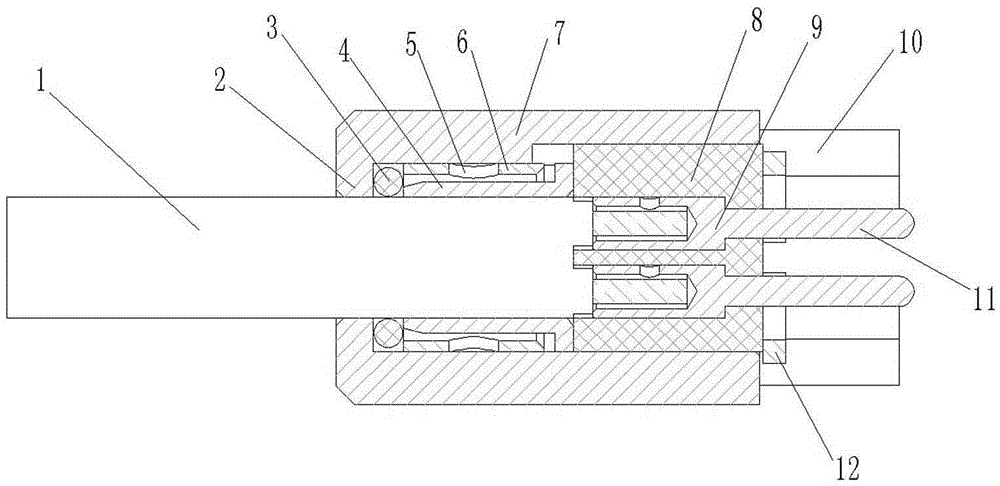

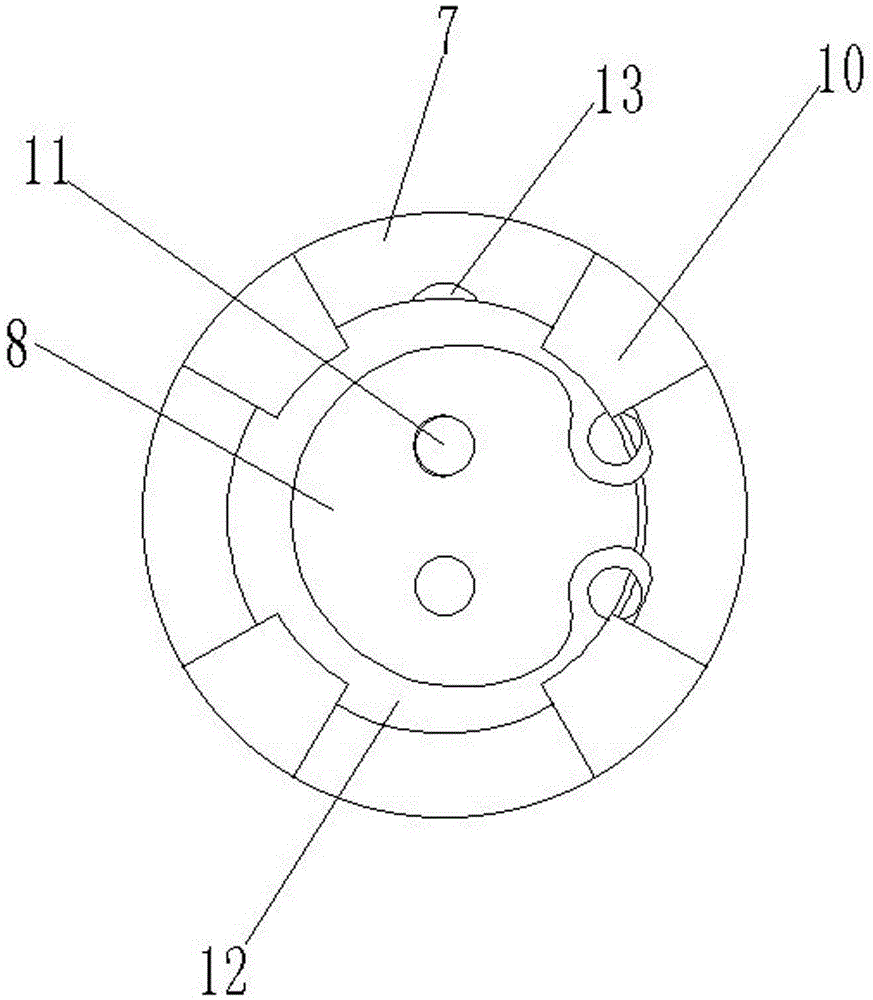

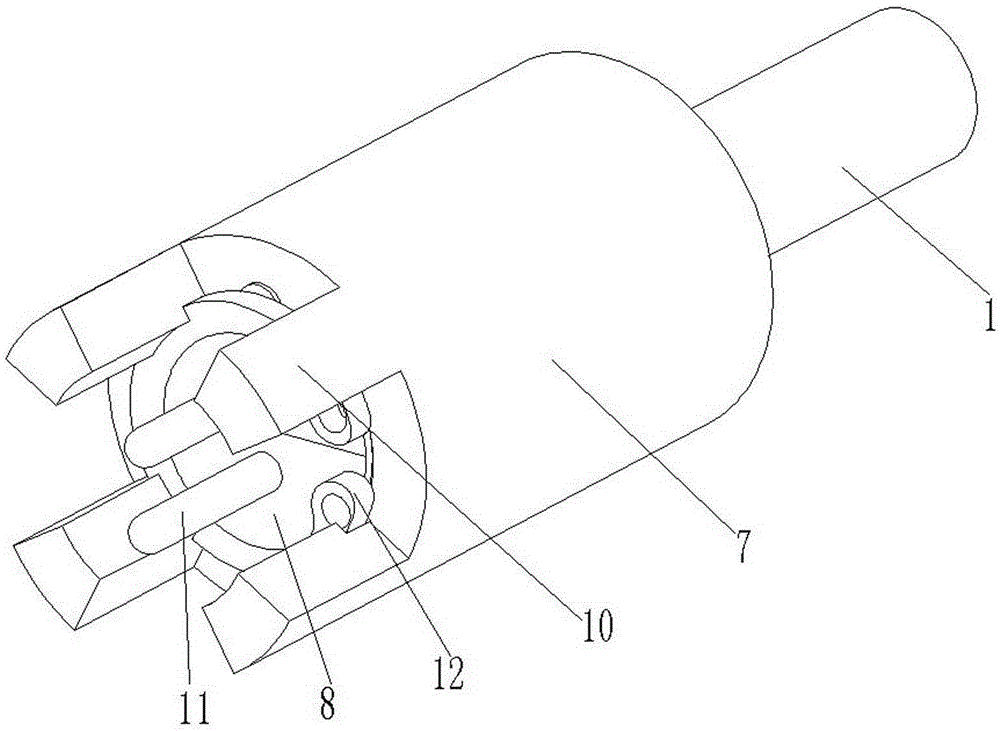

[0030] Examples of connecting components used to connect wires to printed boards are Figure 1~13 As shown: it includes a wire lead terminal 9 with a conductive pin 11 at the front end, and a wire hole for connecting with a wire at the rear end of the wire lead terminal. The connection assembly also includes a fixed sleeve 7. The fixed sleeve includes a sleeve-shaped body made of metal material whose axis extends along the front-to-back direction. It constitutes the shielding layer limiting surface with the blocking direction facing forward, and the front end of the sleeve-shaped body is arranged with four reinforced grounding pins 10 for welding with the printed board at intervals around the circumference. The inner hole of the sleeve-shaped body is guided from front to back with a shielding layer connection structure and an insulator 8. There are two wire lead terminals 9, and the wires 1 corresponding to the two wire lead terminals 9 are twisted pairs. The insulator is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com