Gear motor and automatic opening and closing unit

A gear motor, motor technology, applied in electrical components, electric components, control mechanical energy and other directions, can solve problems such as hindering gear rotation and short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

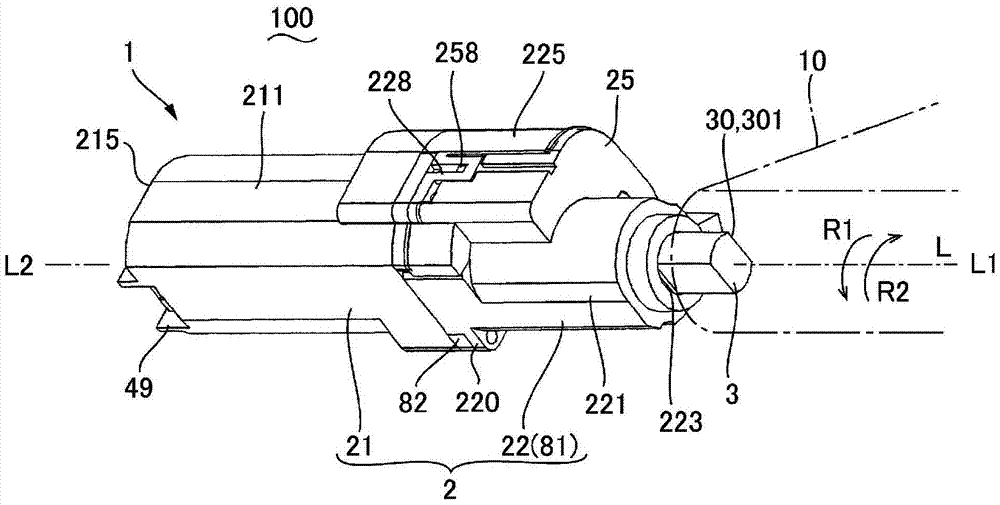

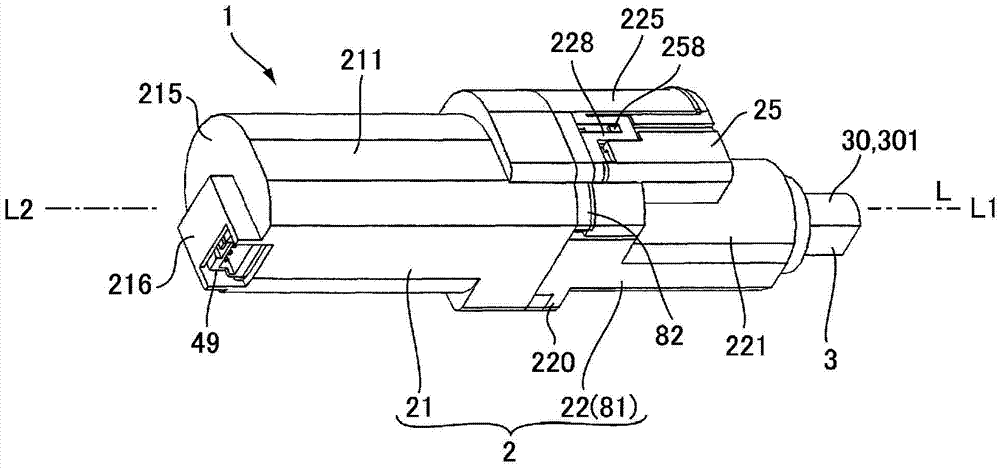

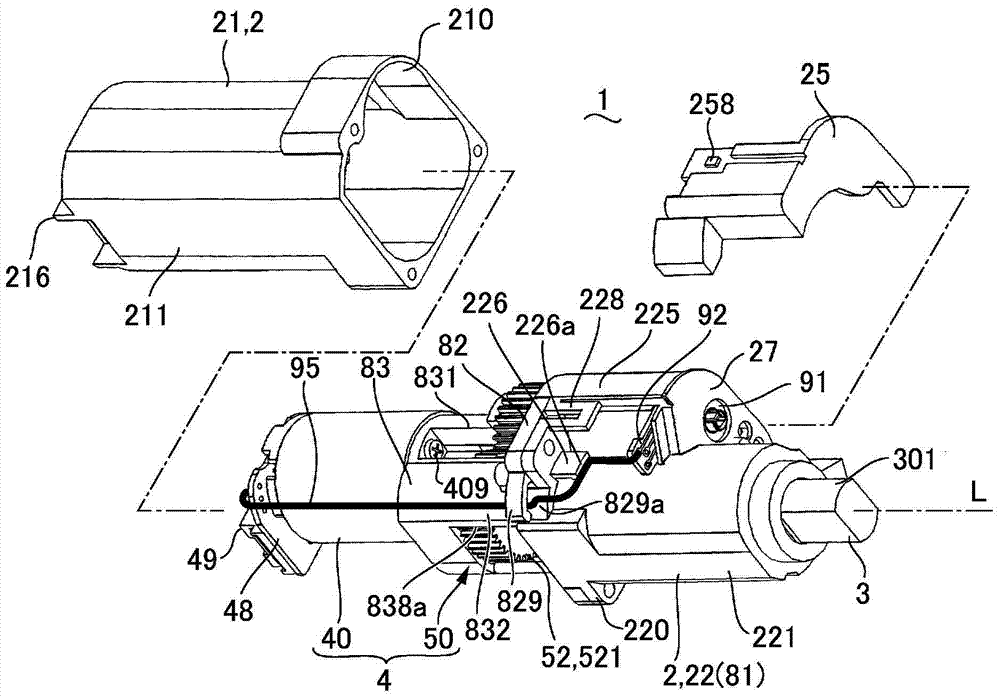

[0075] A gear motor and an automatic opening and closing unit to which the present invention is applied will be described with reference to the drawings. In addition, in the following description, the rotation center axis|shaft of an output shaft is demonstrated as the axis|shaft L. As shown in FIG.

[0076] (the whole frame)

[0077] Fig. 1 (a) and Fig. 1 (b) are explanatory diagrams having an automatic opening and closing unit 100 to which the gear motor 1 of the present invention is applied, and Fig. 1 (a) and Fig. 1 (b) protrude from the output shaft 3 respectively A perspective view of the gear motor 1 viewed from one side (one side L1 in the axis L direction) and a perspective view of the gear motor 1 viewed from the opposite side (the other side L2 in the axis L direction) from the side protruding from the output shaft 3 . Fig. 2 (a), Fig. 2 (b), Fig. 2 (c) are explanatory diagrams showing the internal structure of the gear motor 1 to which the present invention is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com