Coil component

A technology of coil components and wires, applied in electrical components, transformer/inductor coil/winding/connection, transformer/inductor components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

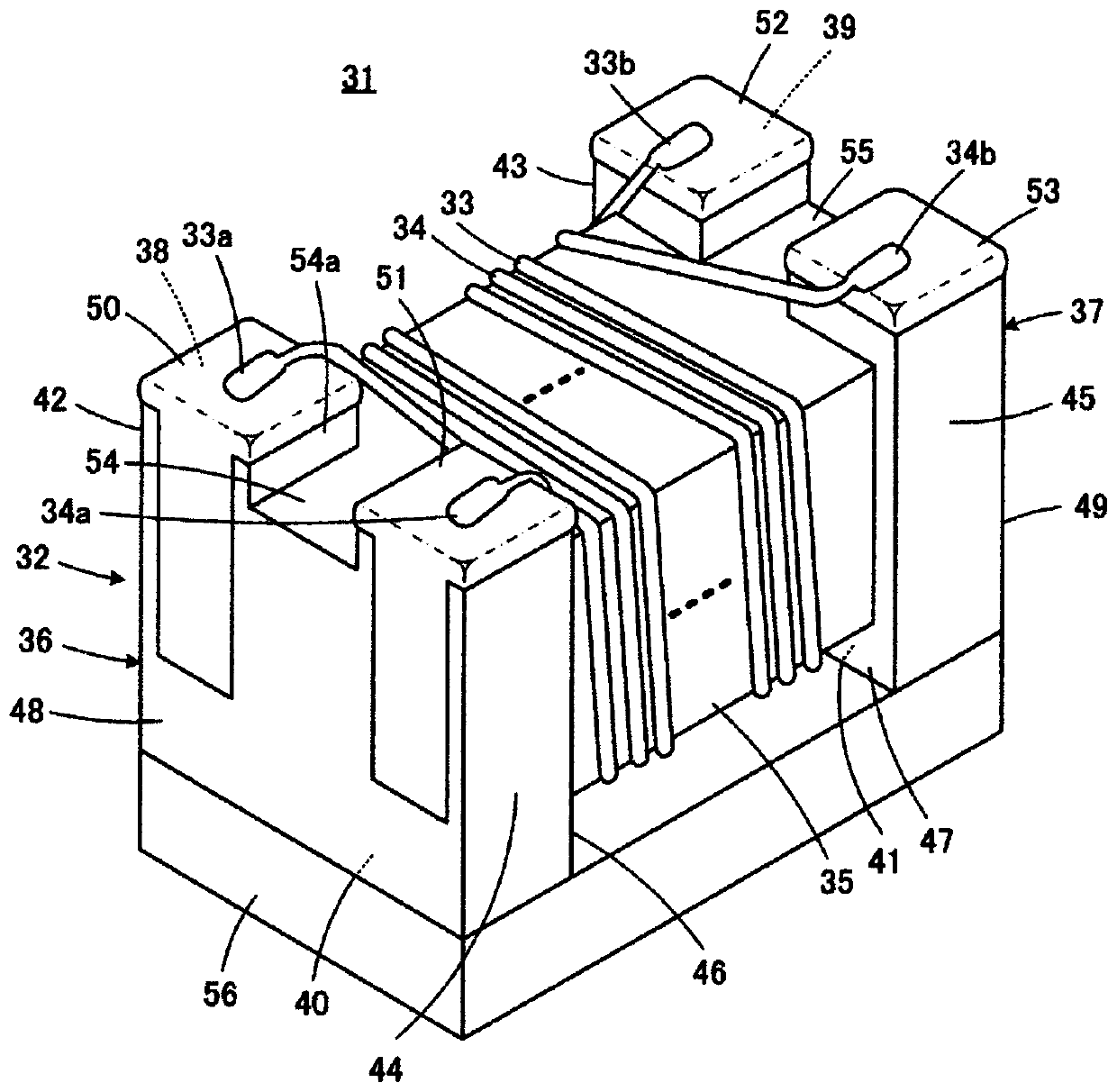

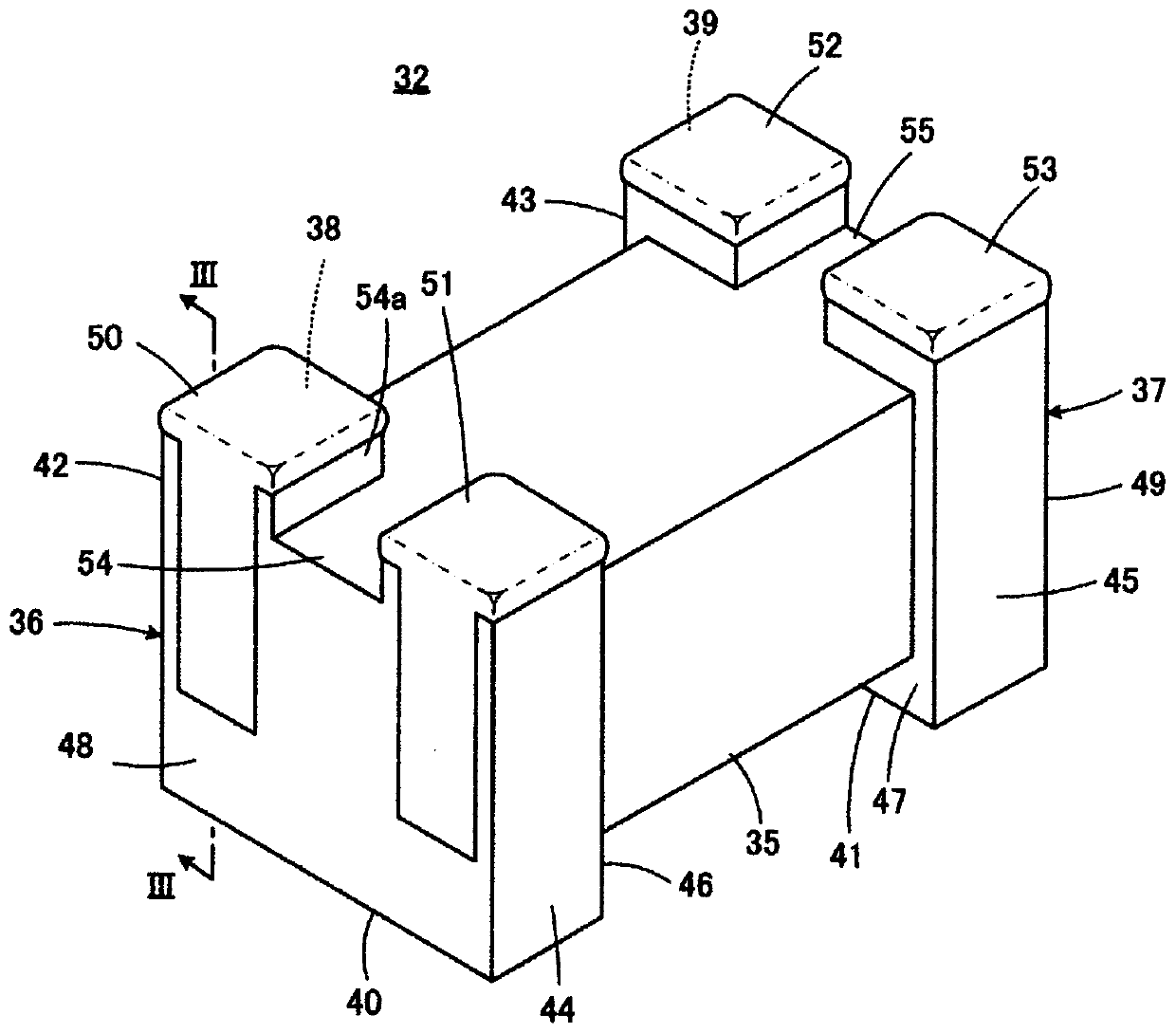

[0030] refer to figure 1 and figure 2 The coil element 31 according to one embodiment of the present disclosure will be described. exist figure 1 and figure 2 In , the coil element 31 and the drum-shaped core 32 are shown so that the surface facing the mounting substrate is upward. The illustrated coil element 31 constitutes, for example, a common mode choke coil.

[0031] The drum-shaped core 32 included in the coil element 31 includes: a winding core portion 35 for arranging the first wire 33 and the second wire 34 and extending in the axial direction; The first flange portion 36 and the second flange portion 37 are provided at the second end. The drum core 32 may be made of a non-conductive material, more specifically, a non-magnetic body such as alumina, a magnetic body such as ferrite, or resin, but is preferably made of ceramics such as alumina or ferrite.

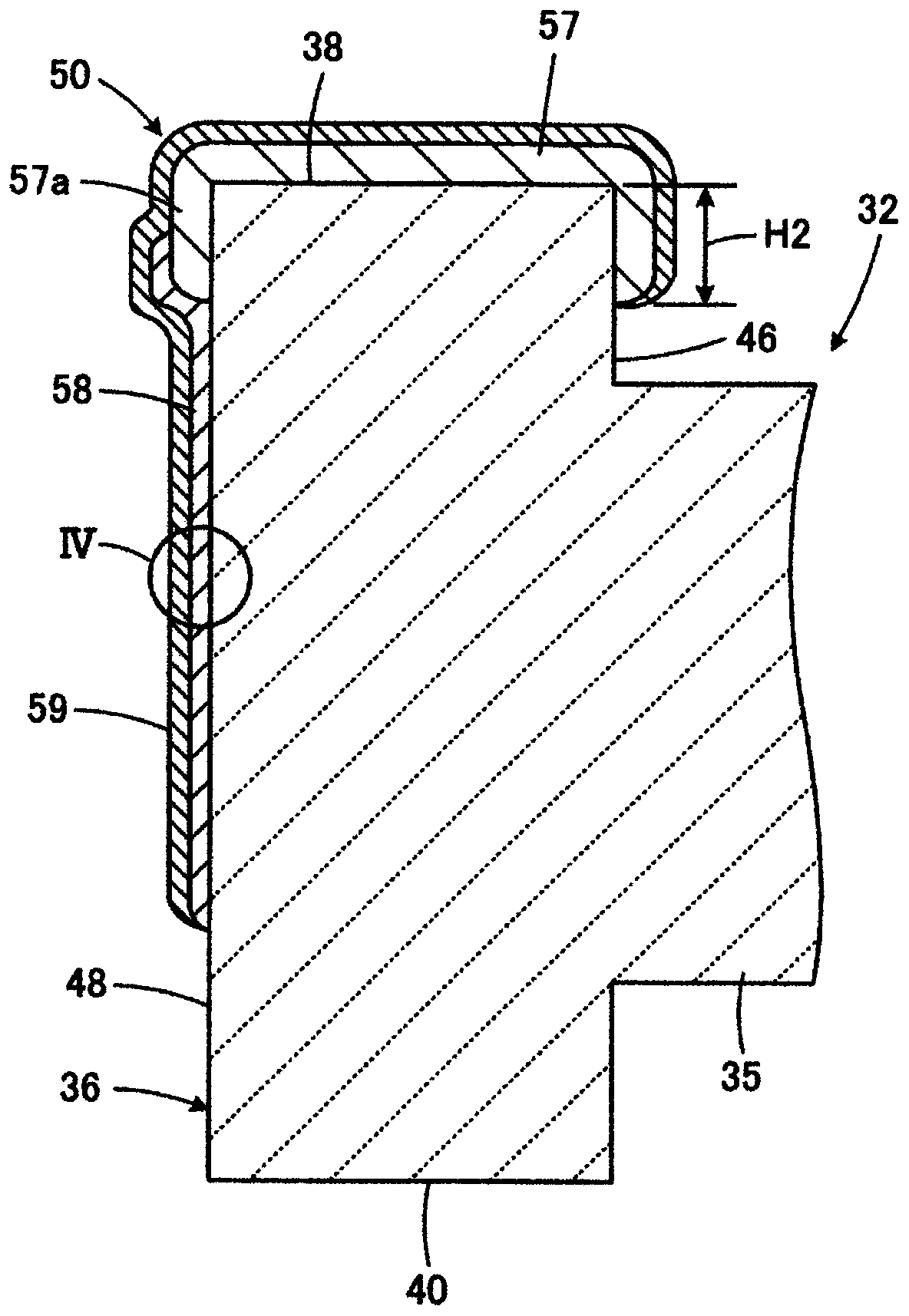

[0032]The winding core portion 35 and the first flange portion 36 and the second flange portion 37 inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com