Packaging structure and packaging process for battery electrode plate

A technology of battery pole piece and packaging process, applied in non-aqueous electrolyte battery electrodes, secondary batteries, structural parts, etc., can solve the problems of active material layer peeling, mutual contact, battery damage, etc., to achieve good stability, not easy to contact , to avoid the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

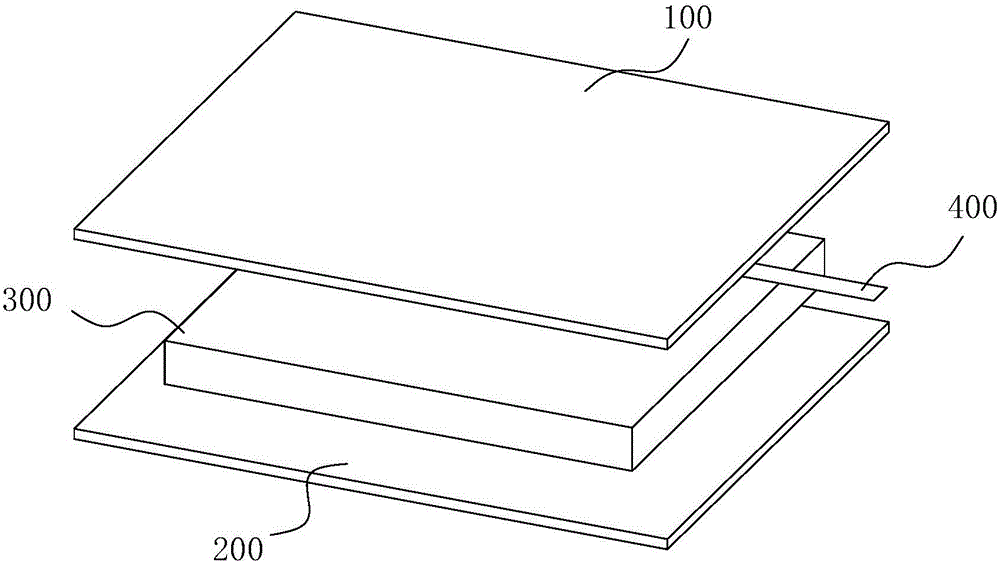

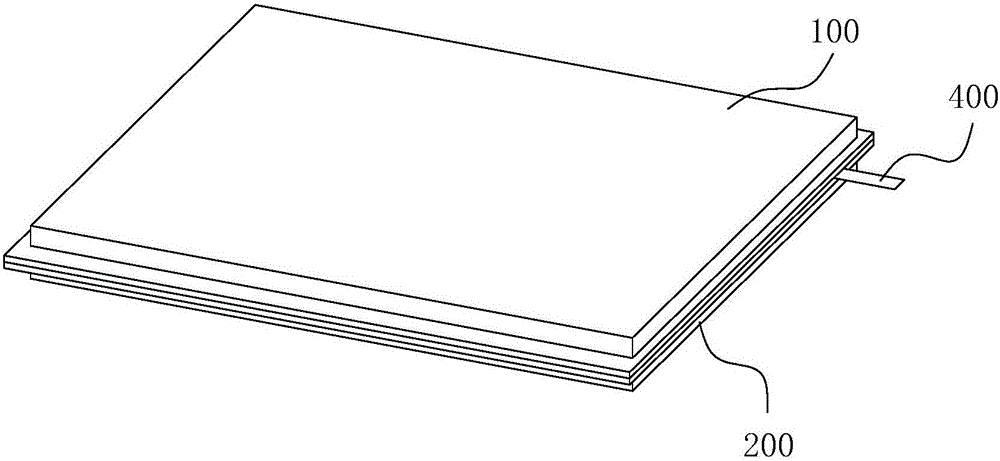

[0032] figure 1 It is a schematic diagram of the disassembled state of the battery pole piece packaging structure described in Embodiment 1 of the present invention; figure 2 It is a structural schematic diagram of the battery pole piece packaging structure described in Embodiment 1 of the present invention after pressing and bonding; figure 1 , 2 As shown, a battery pole sheet packaging structure includes an electrode sheet 300 and a diaphragm, the electrode sheet 300 has a first surface and a second surface opposite to each other, and the diaphragm includes electrodes corresponding to the first surface and the second The first diaphragm 100 and the second diaphragm 200 arranged on the surface, the first diaphragm 100 and the second diaphragm 200 are connected to each other at the periphery of the electrode sheet 300, and the diaphragm is provided with a pole piece for connecting the pole piece. The tab mounting hole of the ear 400.

[0033] In this embodiment, the first ...

Embodiment 2

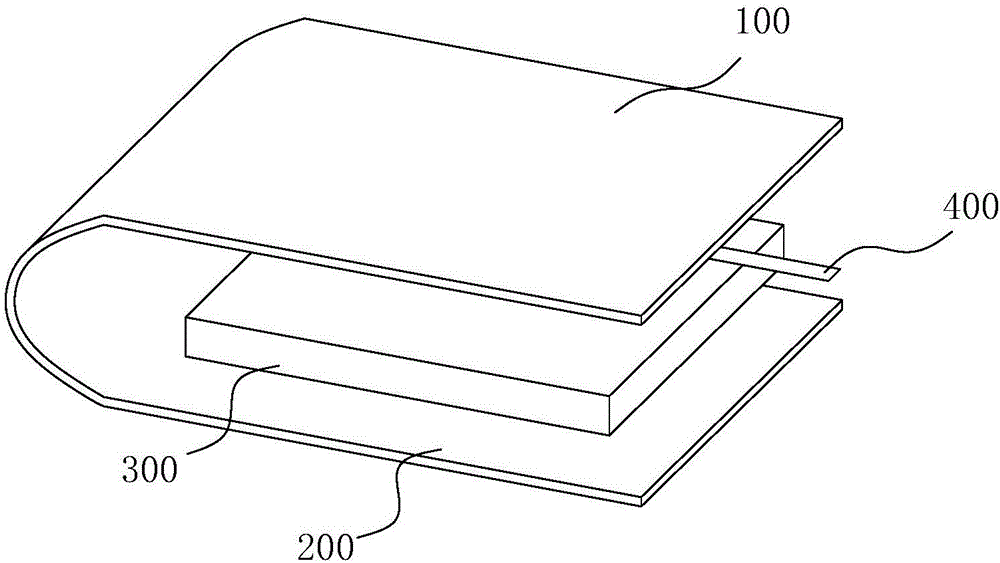

[0044] image 3 It is a schematic diagram of the disassembled state of the battery pole piece packaging structure described in Embodiment 2 of the present invention; image 3 As shown, a battery pole sheet packaging structure includes an electrode sheet 300 and a diaphragm, the electrode sheet 300 has a first surface and a second surface opposite to each other, and the diaphragm includes electrodes corresponding to the first surface and the second The first diaphragm 100 and the second diaphragm 200 arranged on the surface, the first diaphragm 100 and the second diaphragm 200 are connected to each other at the periphery of the electrode sheet 300, and the diaphragm is provided with a pole piece for connecting the pole piece. The tab mounting hole of the ear 400.

[0045] In this embodiment, the sheet structure of the first diaphragm 100 and the second diaphragm 200 is respectively located on the first surface and the second surface of the electrode sheet 300 after being bent,...

Embodiment 3

[0054] Figure 4 It is a schematic diagram of the decomposed state of the battery pole piece packaging structure described in Embodiment 3 of the present invention; Figure 4 As shown, in this embodiment, a bag-shaped separator with only one side opening is used as the first separator 100 and the second separator 200, and after the electrode sheet 300 is loaded into the bag-shaped separator from the opening, the opening is pressed and bonded, and the pressure During the bonding process, a tab installation hole is reserved for the protrusion of the tab 400. In this embodiment, the pressing bonding can be cold pressing bonding or hot pressing bonding.

[0055] The battery pole piece with this encapsulation structure can avoid the leakage of the active material in the battery, the contact between the pole pieces is not easy to occur, and the hidden danger of short circuit is avoided; the battery produced by this process has good stability and can be applied to large The producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com