Metal fine-rolling method and metal fine-rolling device

A metal and rolling process technology, which is applied in the field of metal micro-rolling method and its device, can solve problems such as unrolling, and achieve the effects of reducing rolling force, small machine type, and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below in conjunction with the accompanying drawings.

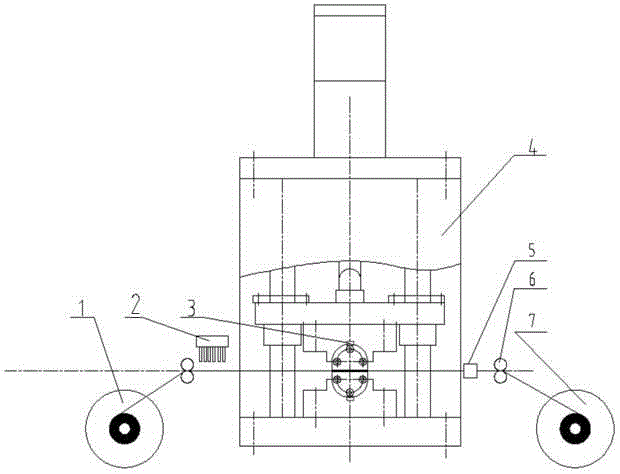

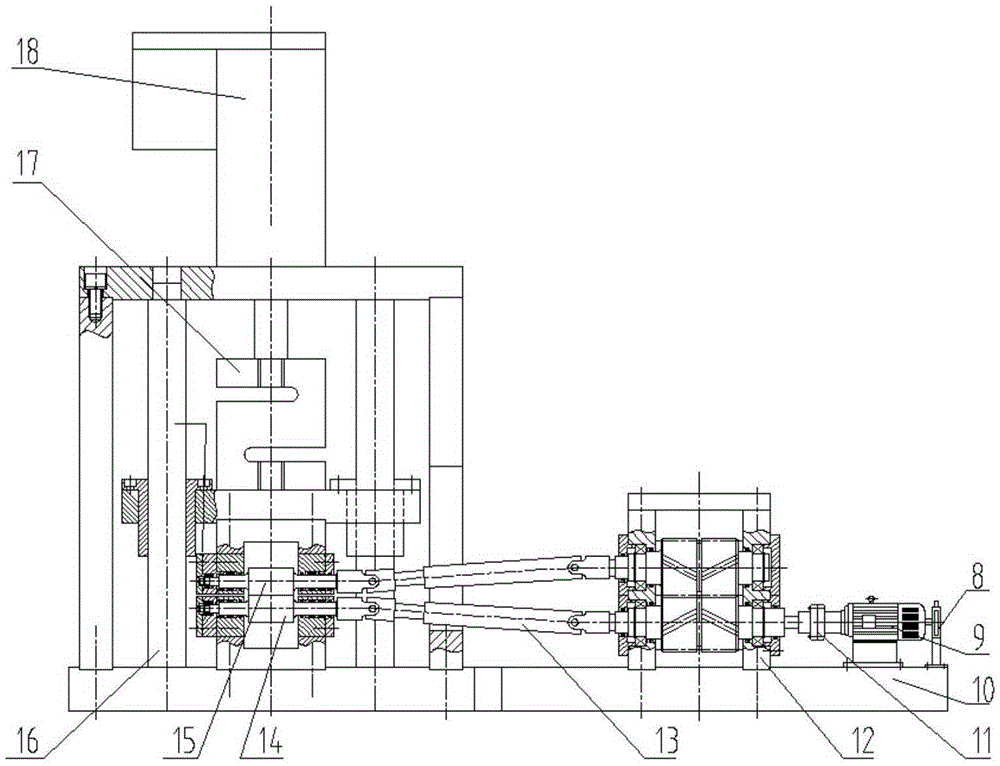

[0020] Such as figure 1 and figure 2 As shown, a metal micro-rolling method and its device, preset relevant rolling parameters in the computer, start the computer control system, start the PLC to enter the automatic control state, and the motor of the unwinding mechanism drives the unwinding mechanism 1 to start rolling. The rolling material passes through the tension roller and enters the lubrication mechanism 2. The lubrication mechanism 2 detects that the rolling material enters, and automatically starts the nozzle of the lubrication mechanism 2 to lubricate the rolling material. The lubricated rolling material enters the precision rolling mill 4 for rolling. The rolling process is: the automatic control system starts the servo motor 9 through the setting of parameters, and the power is input to the reducer 12 through the coupling 11, and the reducer 12 div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com