Improved heat dissipater assembly equipment with cylinder bottom adjusting screws

A technology for adjusting screws and assembling equipment, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost, poor assembly quality, time-consuming and labor-intensive, etc., and achieve the effect of compact structure, manpower saving, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

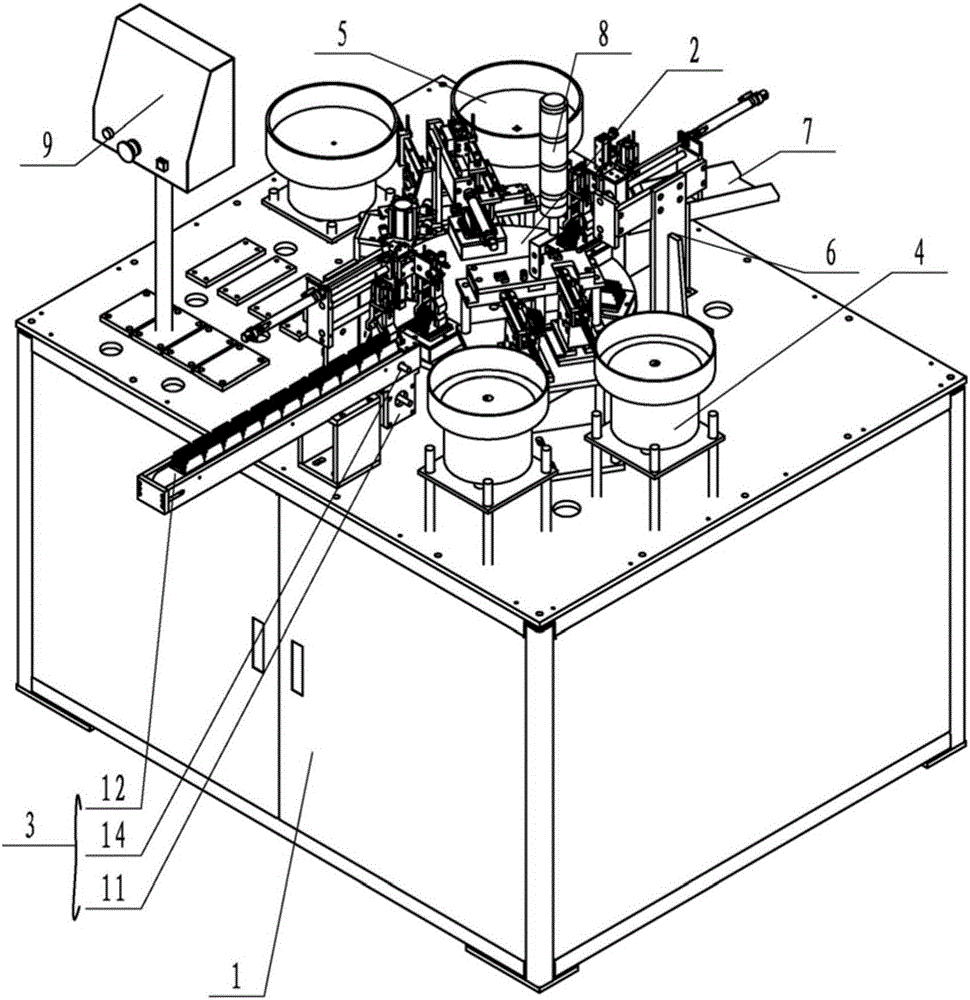

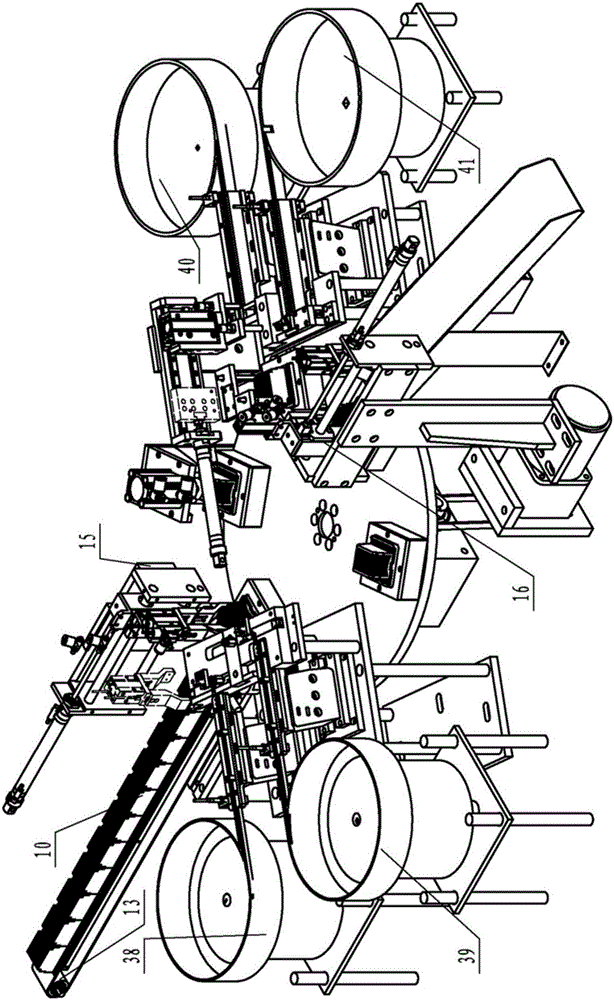

[0038] Such as Figure 1-13 As shown, the present invention includes a frame 1 and a rotating worktable 2 respectively arranged on the frame 1, a feeding and conveying device 3, a rubber nailing device 4, a bullet nailing device 5, a pressing device 6 and a discharging device. Device 7; the feeding and conveying device 3, the plastic nailing device 4, the pressing device 6, the discharging device 7 and the projectile nail device 5 are arranged in a circle based on the axis of the rotating worktable 2;

[0039] The rotary workbench 2 is provided with a positioning mold 33 for mounting the radiator 10;

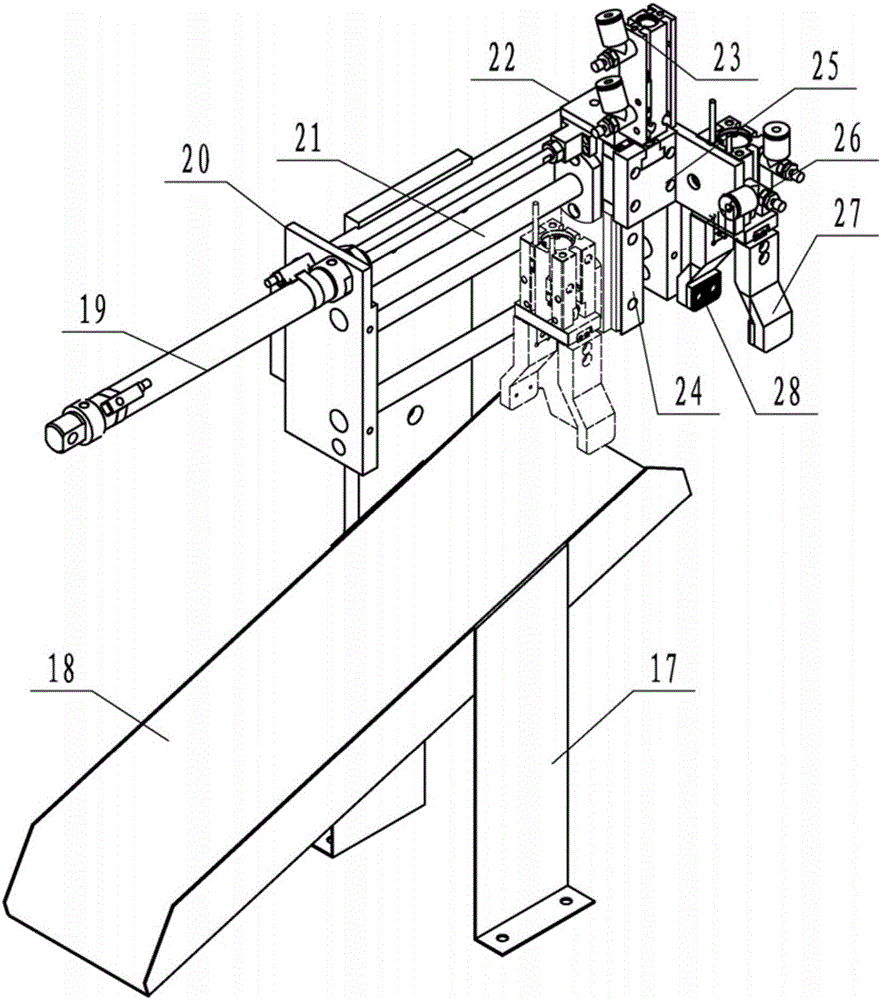

[0040] The feeding and conveying device 3 includes a feeding servo motor 11 arranged on the frame 1, a driving wheel 14 connected to the feeding servo motor 11, a driven wheel 13 arranged on the side of the driving wheel 14, and a driving wheel 14 and The conveyor belt 12 on the driven wheel 13 for loading and conveying the radiator 10 and the loading manipulator 15 provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com