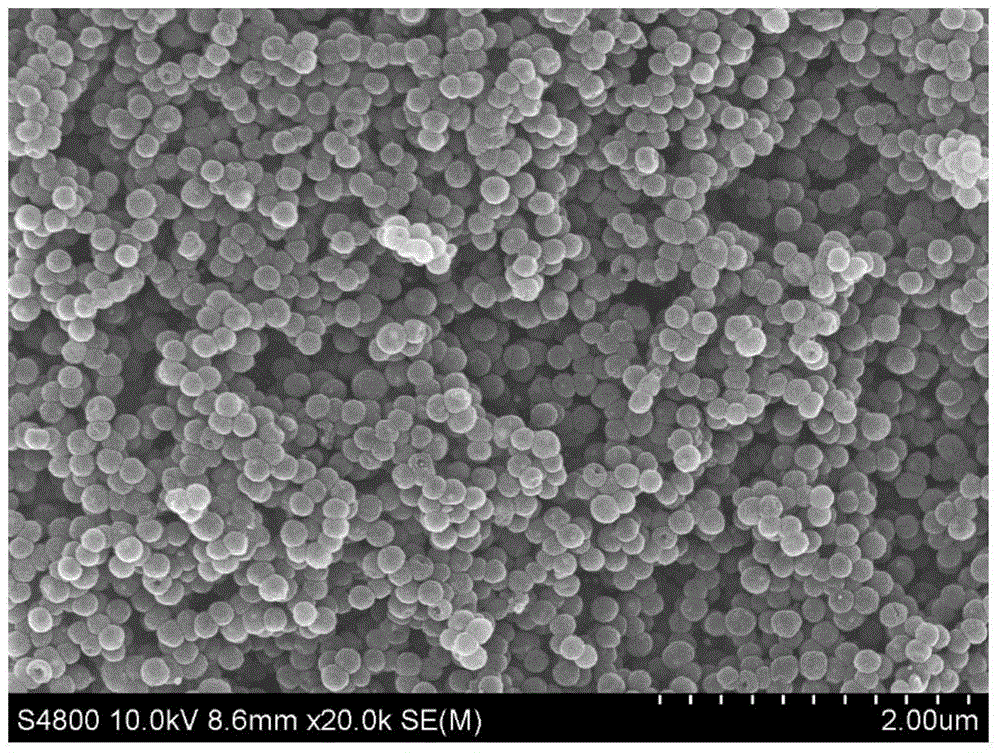

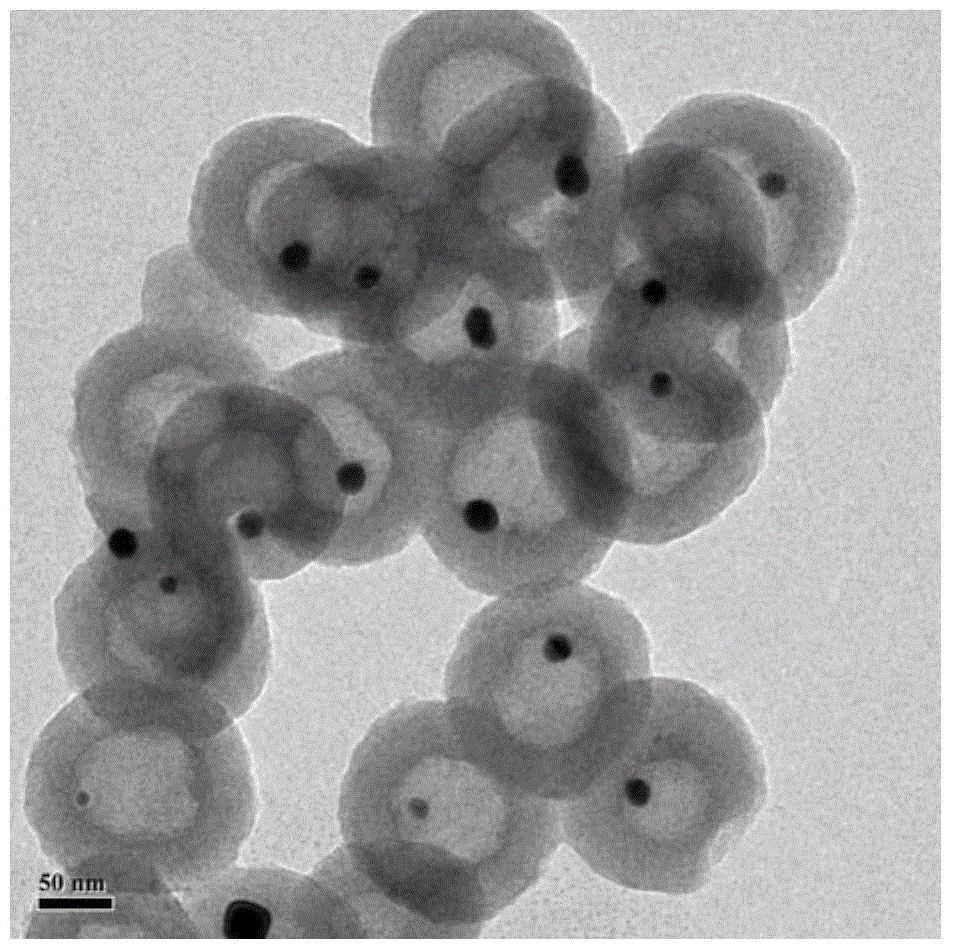

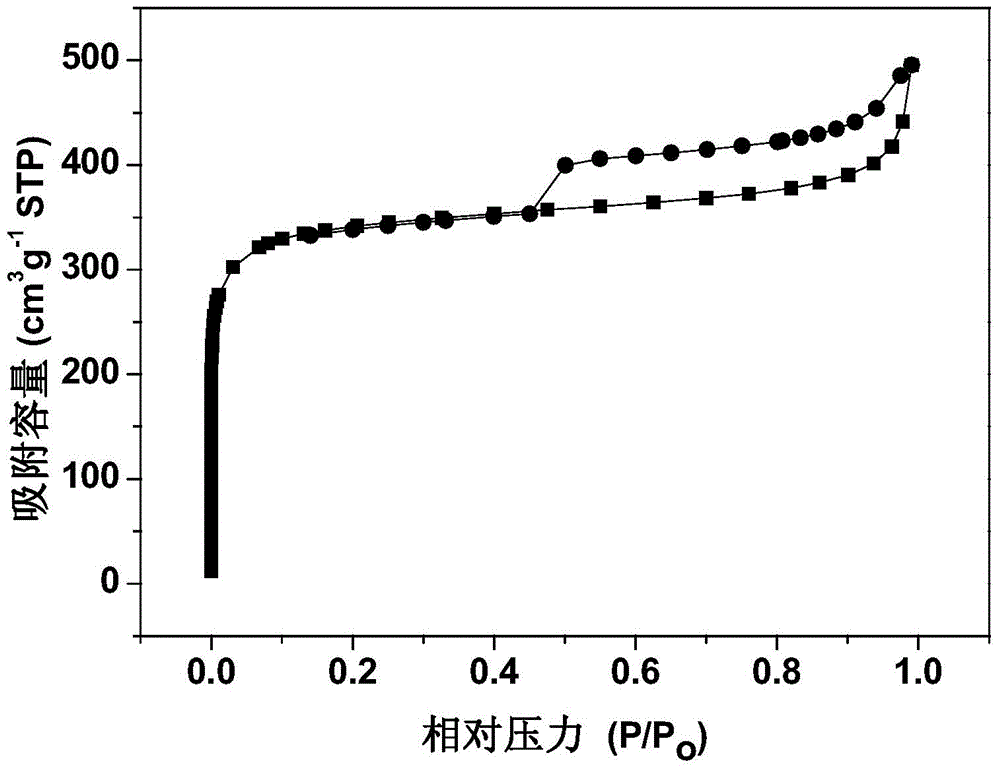

Egg yolk‑eggshell structure au@hollow carbon nanosphere composite material and its preparation and application

A technology of carbon nanospheres and composite materials, applied in the field of materials, can solve the problems of low porosity of carbon shell, unfavorable noble metal yolk core, cumbersome experimental operation of removing hard template, etc., and achieve good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare an egg yolk-eggshell structure Au@hollow carbon nanosphere composite material according to the following steps:

[0038] (1) Weigh 0.0216g of HAuCl 4 Dissolve in 237.5mL deionized water, add it to a 500mL three-necked flask equipped with a water conduit, reflux condenser, vacuum plug, and magnet, stir vigorously with a magnet, heat to reflux, and heat to boiling to obtain a chloroauric acid solution ; Weigh 0.125g of trisodium citrate and dissolve it in 12.5mL of deionized water to obtain an aqueous solution of sodium citrate, then quickly add it to the chloroauric acid solution at one time, continue to heat and reflux for 30min, and cool to room temperature to obtain nano-gold hydrosol;

[0039] (2) Centrifuge the nano-gold hydrosol prepared in step (1) (11800rpm, centrifuge for 30min), remove the supernatant, concentrate to 30-40mL, add 6mL of prepared TritonX-100 solution (0.01g / mL ), add deionized water according to the actual solution amount to make the to...

Embodiment 2

[0047] Prepare an egg yolk-eggshell structure Au@hollow carbon nanosphere composite material according to the following steps:

[0048] (1) Weigh 0.0216g of HAuCl 4 Dissolve in 237.5mL deionized water, add it to a 500mL three-necked flask equipped with a water conduit, reflux condenser, vacuum plug, and magnet, stir vigorously with a magnet, heat to reflux, and heat to boiling to obtain a chloroauric acid solution ; Weigh 0.125g of trisodium citrate and dissolve it in 12.5mL of deionized water to obtain an aqueous solution of sodium citrate, then quickly add it to the chloroauric acid solution at one time, continue to heat and reflux for 30min, and cool to room temperature to obtain nano-gold hydrosol;

[0049] (2) Centrifuge the nano-gold hydrosol prepared in step (1) (11800rpm, centrifuge for 30min), remove the supernatant, concentrate to 30-40mL, add 6mL of prepared TritonX-100 solution (0.01g / mL ), add deionized water according to the actual solution amount to make the to...

Embodiment 3

[0053] Prepare an egg yolk-eggshell structure Au@hollow carbon nanosphere composite material according to the following steps:

[0054] (1) Weigh 0.0216g of HAuCl 4 Dissolve in 237.5mL deionized water, add it to a 500mL three-necked flask equipped with a water conduit, reflux condenser, vacuum plug, and magnet, stir vigorously with a magnet, heat to reflux, and heat to boiling to obtain a chloroauric acid solution ; Weigh 0.125g of trisodium citrate and dissolve it in 12.5mL of deionized water to obtain an aqueous solution of sodium citrate, then quickly add it to the chloroauric acid solution at one time, continue to heat and reflux for 30min, and cool to room temperature to obtain nano-gold hydrosol;

[0055] (2) Centrifuge the nano-gold hydrosol prepared in step (1) (11800rpm, centrifuge for 30min), remove the supernatant, concentrate to 30-40mL, add 6mL of prepared TritonX-100 solution (0.01g / mL ), add deionized water according to the actual solution amount to make the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com