Paw for double-position grabbing

A dual-position, gripper technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of easy damage to special-shaped targets, poor stability, poor grasping flexibility, etc., and achieve novel structure settings, low manufacturing costs, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

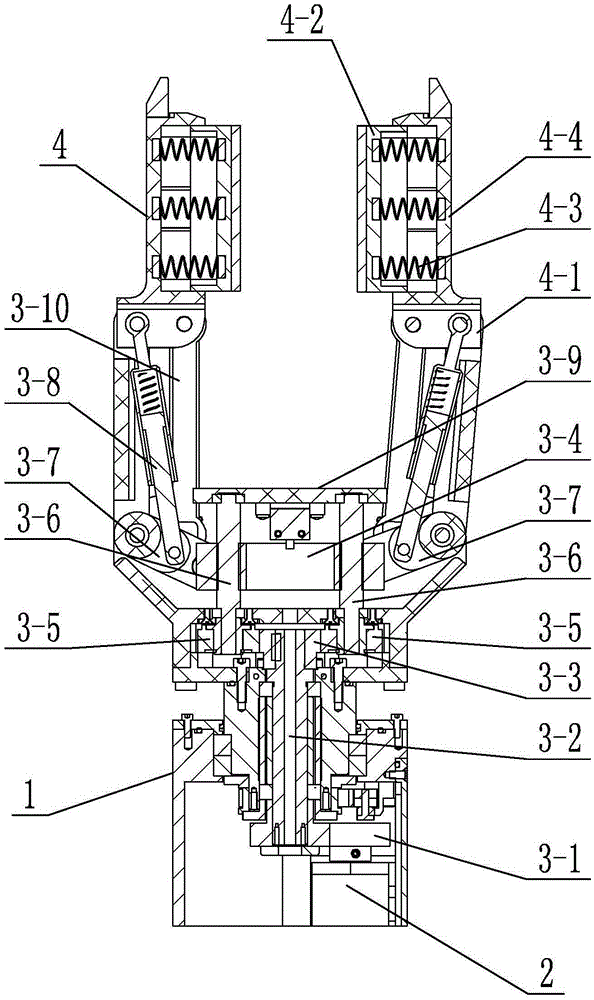

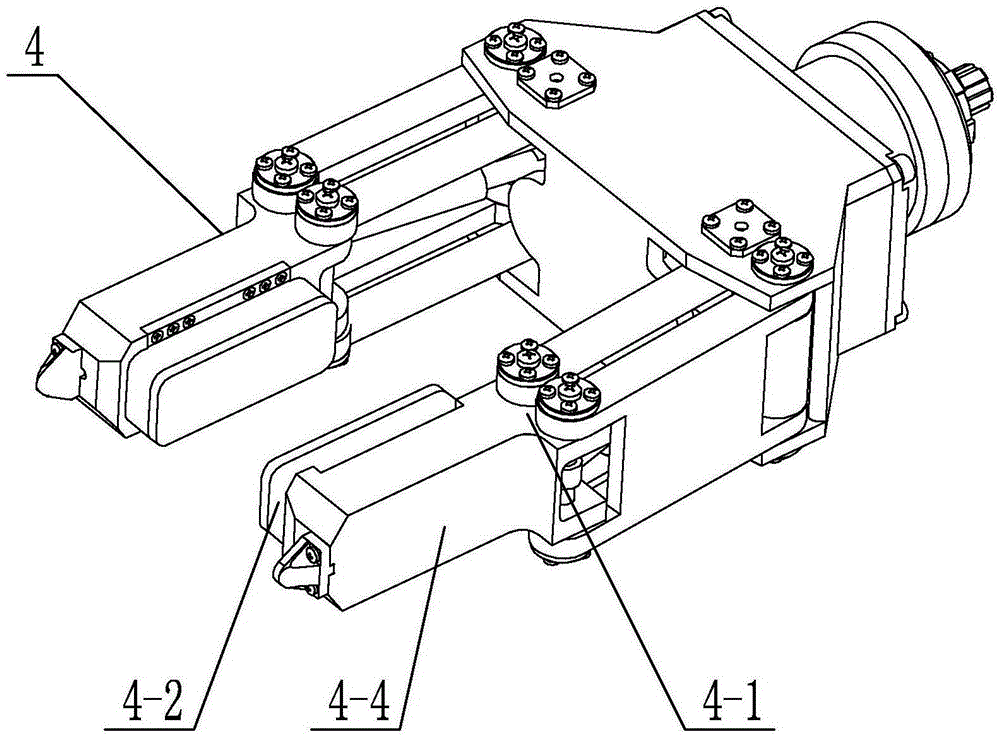

[0014] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, the gripper in this embodiment includes a housing 1, a motor 2, a transmission component and two grasping parts 4;

[0015] Both the motor 2 and the transmission parts are located in the casing 1, and the transmission parts include a first set of gear pairs 3-1, a driving gear connecting shaft 3-2, a driving gear 3-3, a slider 3-4, and a fixed plate 3 -9, two sets of second sets of gear pairs 3-5, two lead screws 3-6, two connecting rods 3-7, two elastic struts 3-8 and two fixed rods 3-10, the motor The output shaft of 2 is connected with one end of the driving gear connecting shaft 3-2 through the first set of gear pairs 3-1, and the other end of the driving gear connecting shaft 3-2 is set with a driving gear 3-3, and the driving gear 3-3 respectively meshes with two sets of second sets of gear pairs 3-5 arranged side by side, and the second set of gear pairs 3-5 is arranged ...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment. In this embodiment, the side surface of the second position grabbing block 4-4 close to the other grabbing part 4 is processed with a groove along its length direction. The elastic component 4 corresponding to the second position grabbing block 4-4 -3 and the first position grasping block 4-2 are both arranged in the groove. The arrangement of the groove in this embodiment is to more effectively shorten the stroke between the grabbing block 4-4 at the second position and the grabbing block 4-2 at the first position. The elastic component 4-3 and the first position grab block 4-2 corresponding to the second position grab block 4-4 refer to the first position grab block 4-2, the elastic component 4-3 and the first position grab block 4-2 in the same gripping part 4. Second position grabs block 4-4. Other unmentioned structures and connections are the same as those in the fir...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 with figure 2 This embodiment is described. In this embodiment, the upper end of each elastic strut 3-8 is hinged on the connection handle 4-1 which is connected close to the fixed rod 3-10. Other unmentioned structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com