Parallel manipulator with driving arm and driven arm convenient to replace

A technology of manipulator and movable shaft, applied in the direction of manipulator, program-controlled manipulator, joint, etc., can solve the problems of inconvenient disassembly, expensive maintenance cost, etc., and achieve the effect of high speed and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

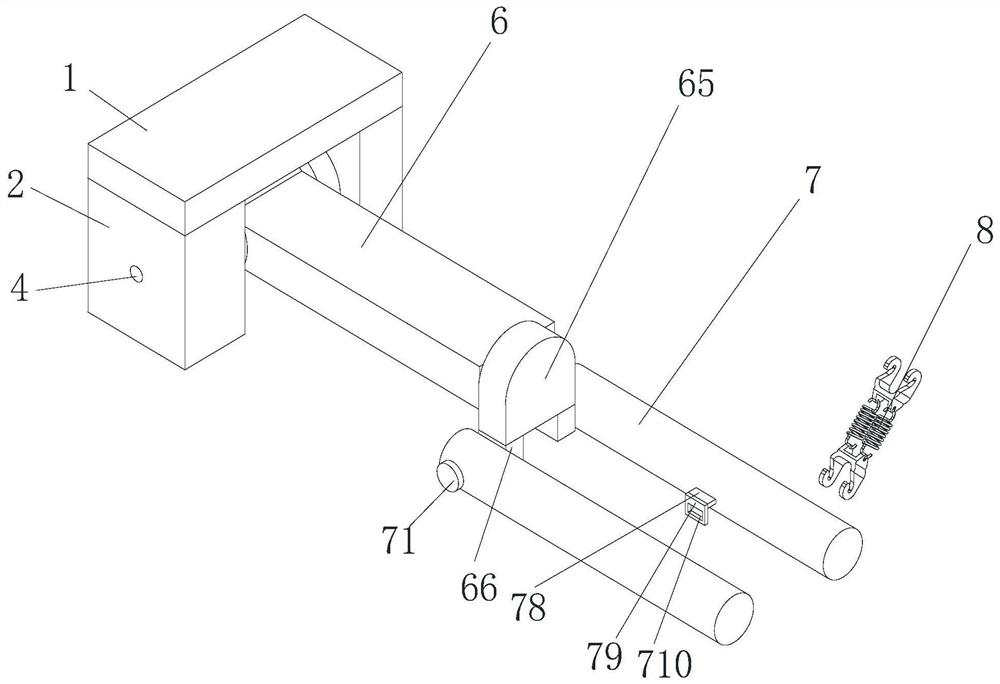

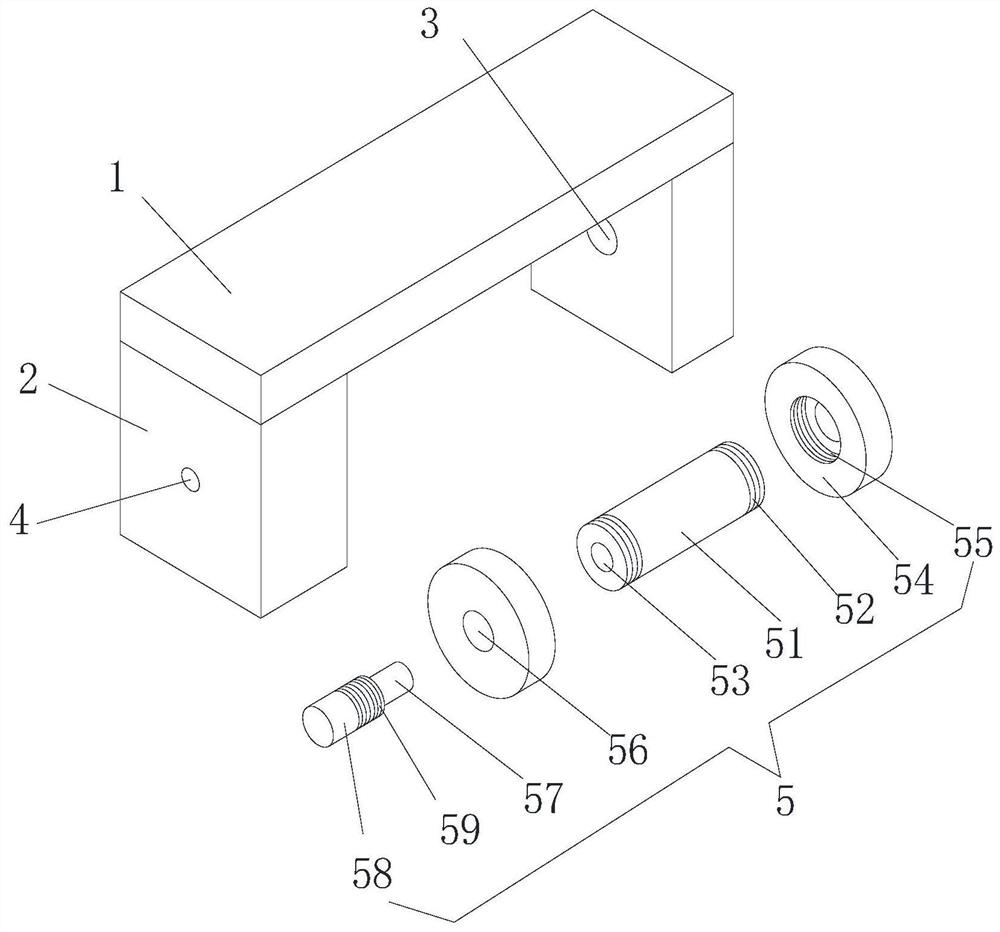

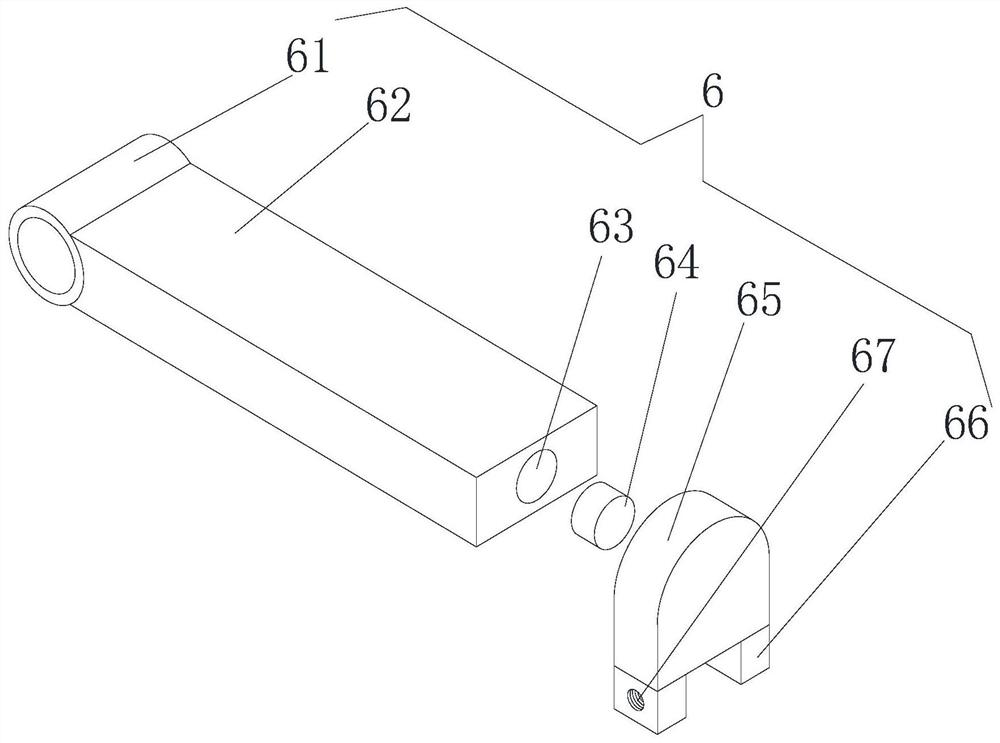

[0027] Example: a parallel manipulator that is convenient to replace the master and slave arms, such as Figure 1-Figure 5 As shown, it includes a fixed block 1, the fixed block 1 is a rectangular block, and two sets of connecting blocks 2 are fixedly installed at the bottom of the fixed block 1, and the two sets of connecting blocks 2 are mirror images on the left and right sides of the bottom of the fixed block 1 Distribution, the two groups of the connecting blocks 2 are provided with movable holes 3 on the side close to each other, the two groups of the connecting blocks 2 are provided with through holes 4 on the side away from each other, and the two groups of the connecting blocks 2 are close to each other. One side is provided with a movable device 5, the rear side of the movable device 5 is provided with an active arm device 6, the rear side of the active arm device 6 is provided with a driven arm device 7, and the interior of the driven arm device 7 is provided Has ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com