Heavy chain conveyor and conveying chain thereof

A chain conveyor and conveyor chain technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of increased wear and tear of the conveyor chain, speed up the wear speed of the conveyor chain, etc., to reduce the load and ensure the effect of stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

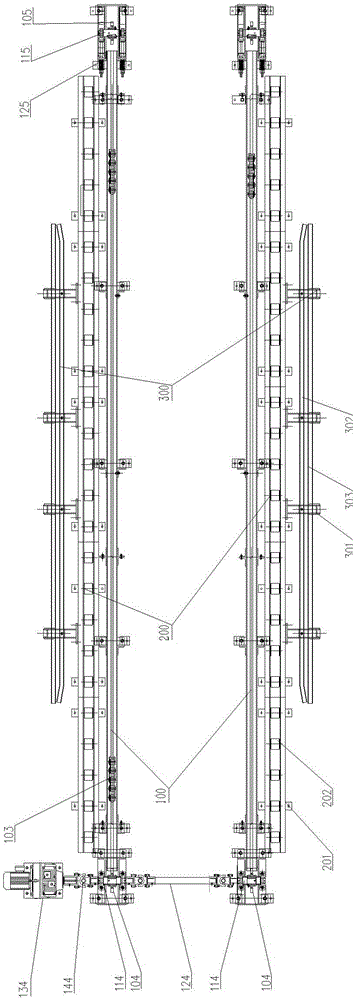

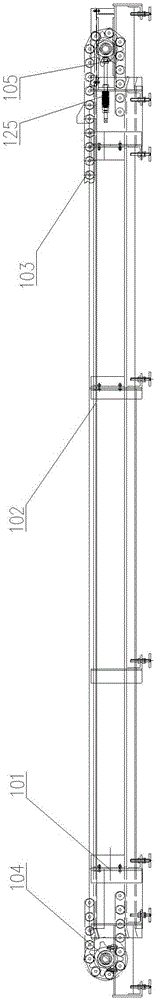

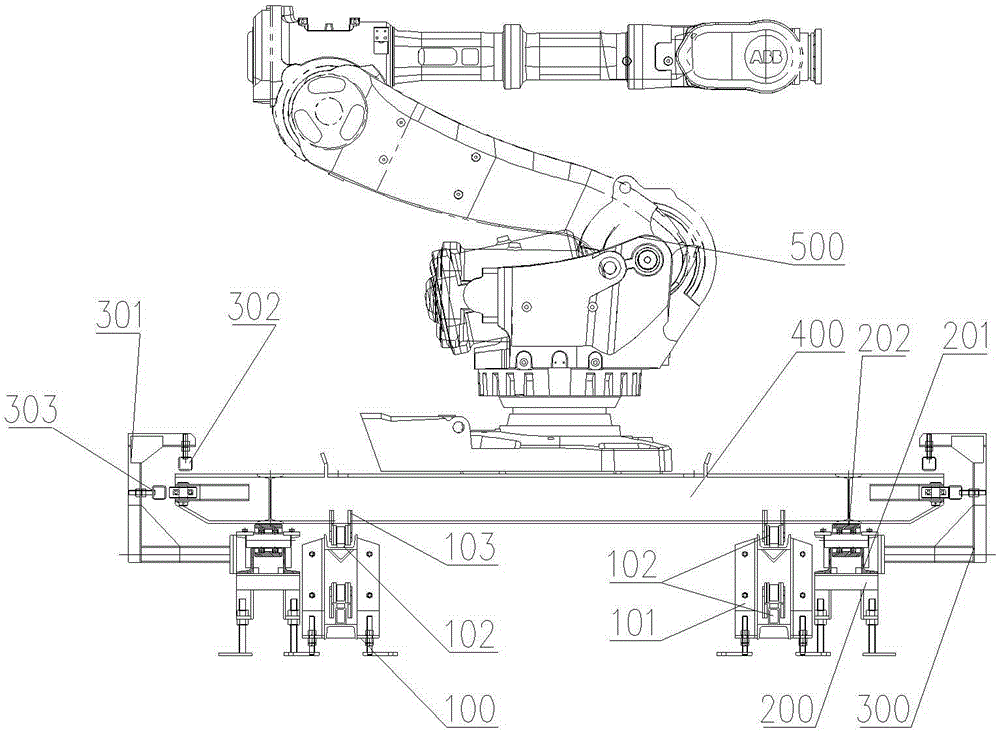

[0023] The embodiment of heavy-duty chain conveyor in the present invention: as Figure 1 to Figure 4 As shown, the conveyor is a chain conveyor with load rails for transporting heavy workpieces (such as robots), and consists of three parts: a conveyor chain mechanism 100 , load rails 200 and an anti-overturn frame 300 .

[0024] The conveyor chain mechanism 100 includes a conveyor frame 101 symmetrically arranged left and right, and two conveyor frames 101 are provided with support rails 102 arranged at intervals between the upper and lower layers. The guide movement is equipped with conveying chains arranged front and back, the conveying chain 103 is composed of a chain body 113 and a push plate 123, wherein the chain body 113 is a roller chain, and there are several pairs of push plates 123, which are arranged at intervals along the pitch direction of the chain body 113 , the distance between two adjacent pairs of push plates 123 is not less than the width of the skid 400, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com