Feeding mechanism

A feeding mechanism and feeding box technology, applied in thin material handling, object separation, pile separation, etc., can solve the problems of high labor intensity, slow feeding speed, easy deformation of thin-walled parts, etc. Feeding efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

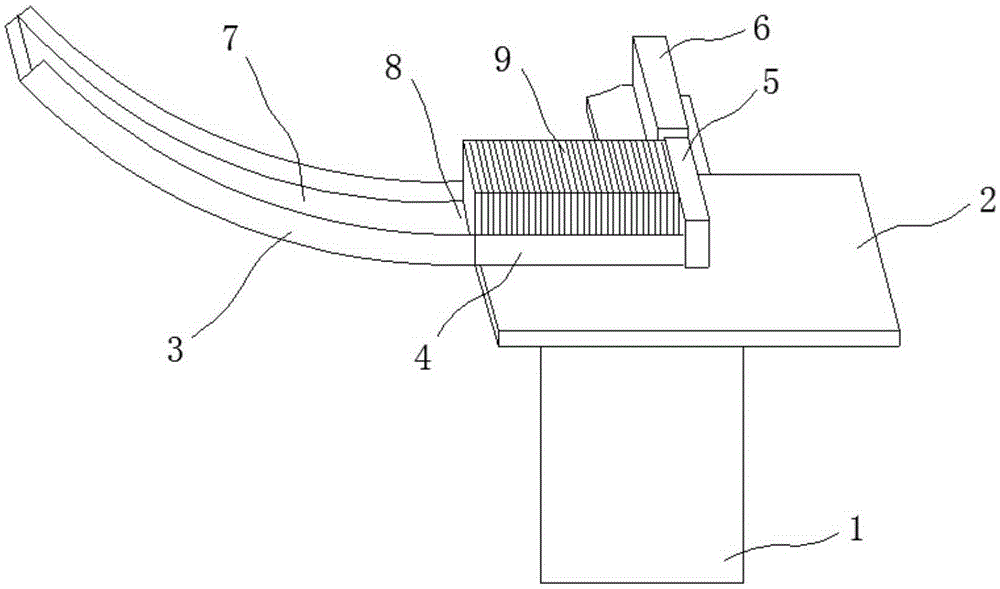

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0016] Such as figure 1 As shown, a feeding mechanism includes a frame 1, the upper end of the frame 1 is fixedly provided with a supporting plate 2, and the upper end of the supporting plate 2 is fixedly provided with a sliding feeding box 3 and a horizontal feeding box 4, and the sliding Feeding box 3 is placed on the side of described horizontal feeding box 4, and described horizontal feeding box 4 is away from the side of described sliding feeding box 3 and is fixedly set pushing material box 5, and described pushing material box 5 and described sliding feeding box 3 and the side perpendicular to the axis of the horizontal feeding box 4 are provided with a rail box 6 capable of magnetically attracting parts 9 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com