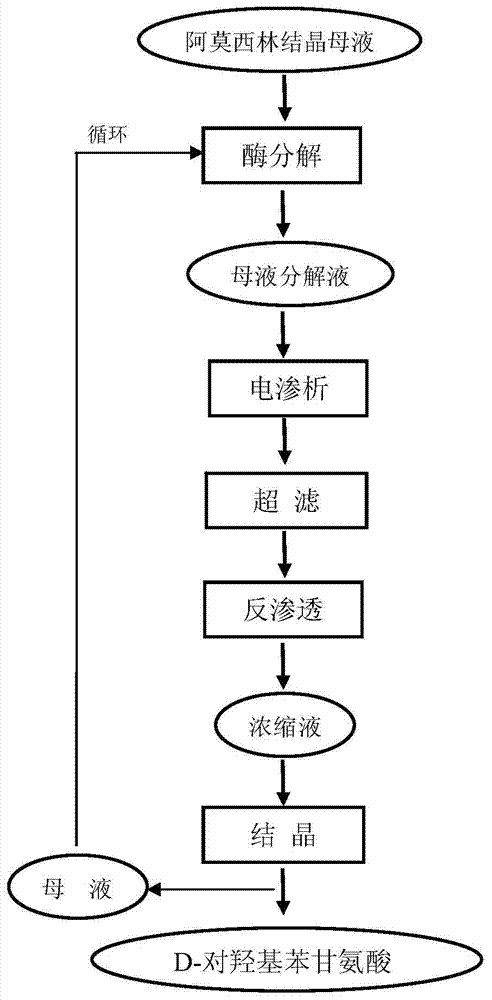

The recovery method of d-p-hydroxyphenylglycine in enzymatic synthesis of amoxicillin crystallization mother liquor

A technology of p-hydroxyphenylglycine and p-hydroxyphenylglycine methyl ester, which is applied in the field of recovery of D-p-hydroxyphenylglycine in the enzymatic synthesis of amoxicillin crystallization mother liquor, which can solve the problems of poor product purity, high energy consumption, and increased recycling costs and other issues to achieve the effect of improving product quality, increasing economic benefits, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Reclaim enzymatic synthesis of D-p-hydroxyphenylglycine in the mother liquor of amoxicillin crystallization as follows:

[0033] (1) Decomposition of amoxicillin mother liquor

[0034] Get the enzymatic synthesis of amoxicillin crystallization mother liquor 150L after the separation of amoxicillin crystallization, wherein the concentration of D-p-hydroxyphenylglycine is 2.84g / L, the concentration of 6-APA is 0.88g / L, and the concentration of amoxicillin is 1.12g / L, the concentration of D-p-hydroxyphenylglycine methyl ester is 0.41g / L, and the conductivity is 28.5ms / cm; Use 40wt% sodium hydroxide solution to adjust the pH of the mother liquor to 8.19, and then pass through it at a flow rate of 80L per hour A circular column bed (enzyme loading capacity of 1 L, height-to-diameter ratio of 8) was equipped with immobilized penicillin acylase (from Hunan Fulaige Biotechnology Co., Ltd., enzyme activity ≥ 250U / g), and the outlet effluent was collected as It is the decomposit...

Embodiment 2

[0042] Reclaim enzymatic synthesis of D-p-hydroxyphenylglycine in the mother liquor of amoxicillin crystallization as follows:

[0043] (1) Decomposition of amoxicillin mother liquor

[0044] Get the enzymatic synthesis of amoxicillin crystallization mother liquor 150L after the separation of amoxicillin crystallization, wherein the concentration of D-p-hydroxyphenylglycine is 2.79g / L, the concentration of 6-APA is 0.78g / L, and the concentration of amoxicillin is 1.18g / L, the concentration of D-p-hydroxyphenylglycine methyl ester is 0.45g / L, and the conductivity is 29.7ms / cm; Use 40wt% sodium hydroxide solution to adjust the pH of the mother liquor to 8.04, and then pass through it at a flow rate of 60L per hour A circular column bed (enzyme loading capacity of 1L, height-to-diameter ratio of 4) equipped with immobilized penicillin acylase (from Hunan Fulaige Biotechnology Co., Ltd., enzyme activity ≥ 250U / g), collect the outlet effluent That is the mother liquor decompositio...

Embodiment 3

[0052] Reclaim enzymatic synthesis of D-p-hydroxyphenylglycine in the mother liquor of amoxicillin crystallization as follows:

[0053] (1) Decomposition of amoxicillin mother liquor

[0054] Get the enzymatic synthesis of amoxicillin crystallization mother liquor 150L after the separation of amoxicillin crystallization, wherein the concentration of D-p-hydroxyphenylglycine is 2.80g / L, the concentration of 6-APA is 0.87g / L, and the concentration of amoxicillin is 1.55g / L, the concentration of D-p-hydroxyphenylglycine methyl ester is 0.39g / L, and the conductivity is 26.3ms / cm; Use 40wt% sodium hydroxide solution to adjust the pH of the mother liquor to 8.32, and then pass through it at a flow rate of 100L per hour A circular column bed (enzyme loading capacity of 1 L, height-to-diameter ratio of 8) equipped with immobilized penicillin acylase (from Hunan Fulaige Biotechnology Co., Ltd., enzyme activity ≥ 250U / g), and the outlet effluent was collected That is the mother liquor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com