Conveying device of fluff feeder

A technology of conveying device and wool feeding machine, which is applied in fiber feeding, textile and paper making, fiber processing, etc. It can solve the problems of reduced working space, inability to meet textile equipment, and small passage, and achieve the effect of convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

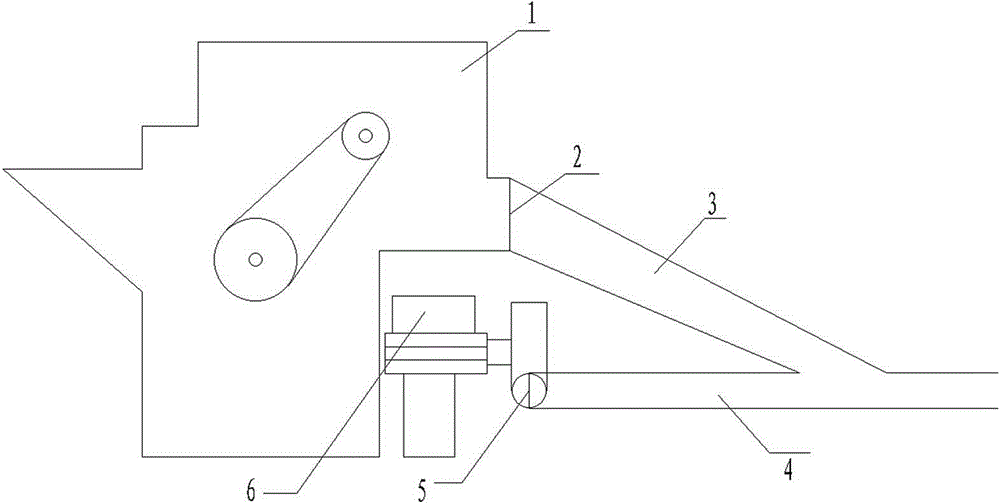

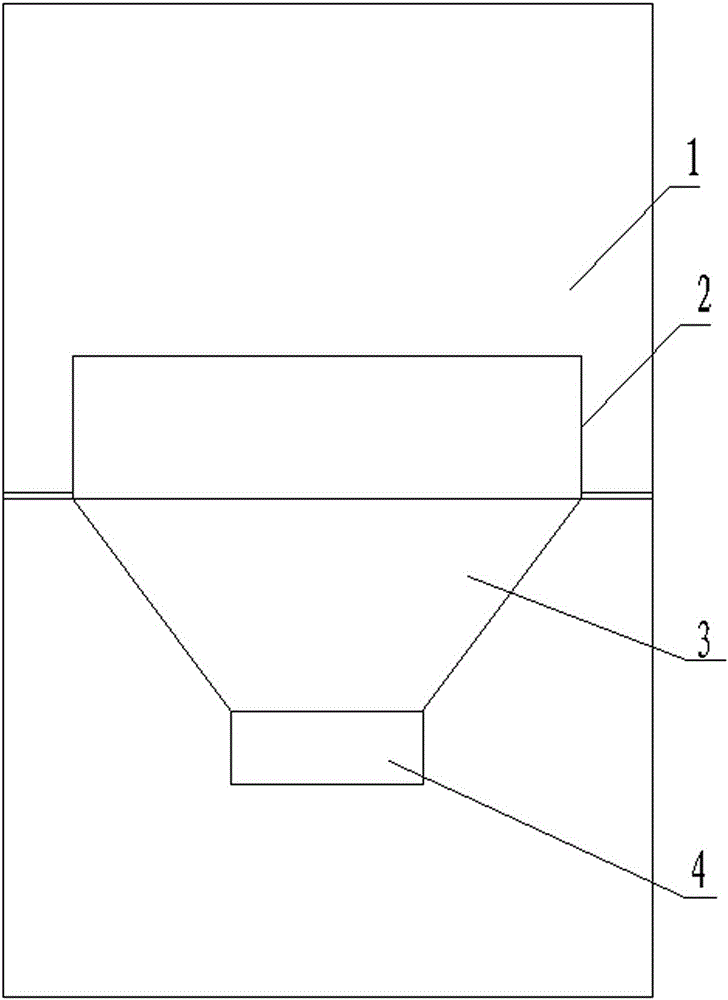

[0015] A conveying device for a wool feeding machine, comprising a pipeline, characterized in that it also includes a slideway 3 connected to the cotton outlet 2 of the wool feeding machine 1, the slideway 3 is connected to the output channel 4 of the blower 5 through a hook provided at the lower end, The blower 5 is provided with a variable speed resistor 6; the slideway 3 forms an inclination angle with the horizontal plane.

[0016] Above-mentioned slideway 3 inclination angles are 30 °.

[0017] The slideway 3 mentioned above is made of aluminum or aluminum alloy.

Embodiment 2

[0019] A conveying device for a wool feeding machine, comprising a pipeline, characterized in that it also includes a slideway 3 connected to the cotton outlet 2 of the wool feeding machine 1, the slideway 3 is connected to the output channel 4 of the blower 5 through a hook provided at the lower end, The blower 5 is provided with a variable speed resistor 6; the slideway 3 forms an inclination angle with the horizontal plane.

[0020] Above-mentioned slideway 3 inclination angles are 45 °.

[0021] The slideway 3 mentioned above is made of aluminum or aluminum alloy.

Embodiment 3

[0023] A conveying device for a wool feeding machine, comprising a pipeline, characterized in that it also includes a slideway 3 connected to the cotton outlet 2 of the wool feeding machine 1, the slideway 3 is connected to the output channel 4 of the blower 5 through a hook provided at the lower end, The blower 5 is provided with a variable speed resistor 6; the slideway 3 forms an inclination angle with the horizontal plane.

[0024] Above-mentioned slideway 3 inclination angles are 60 °.

[0025] The slideway 3 mentioned above is made of aluminum or aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com