Patents

Literature

41results about How to "Adjust the size of the wind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

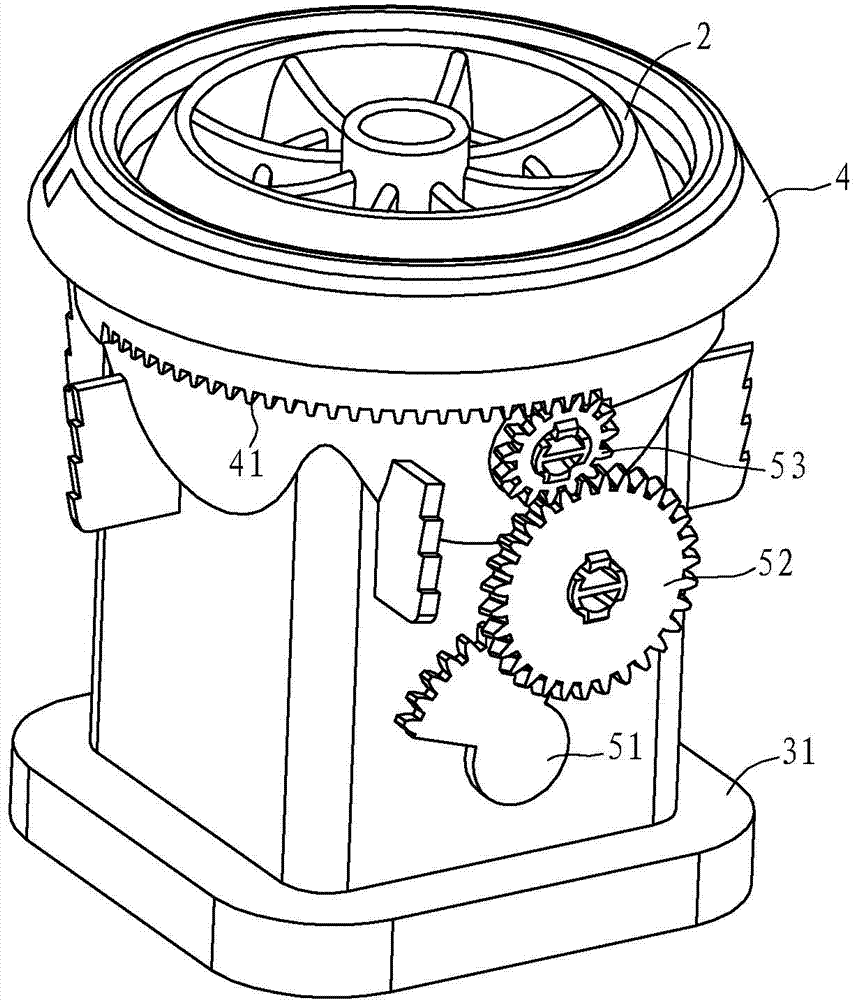

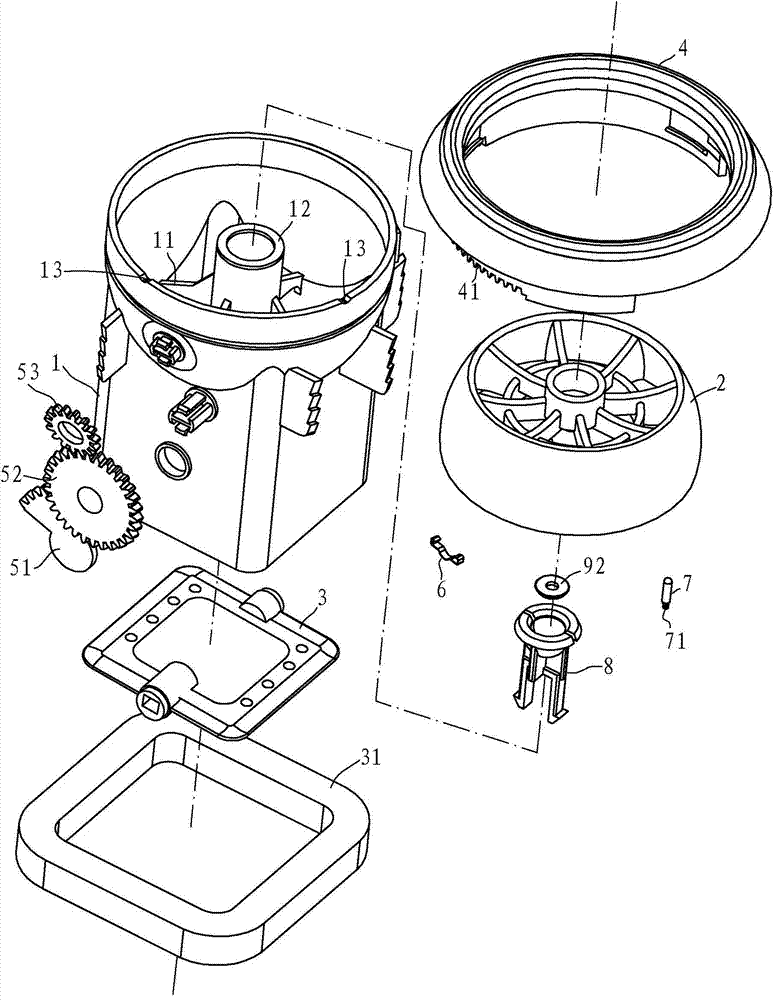

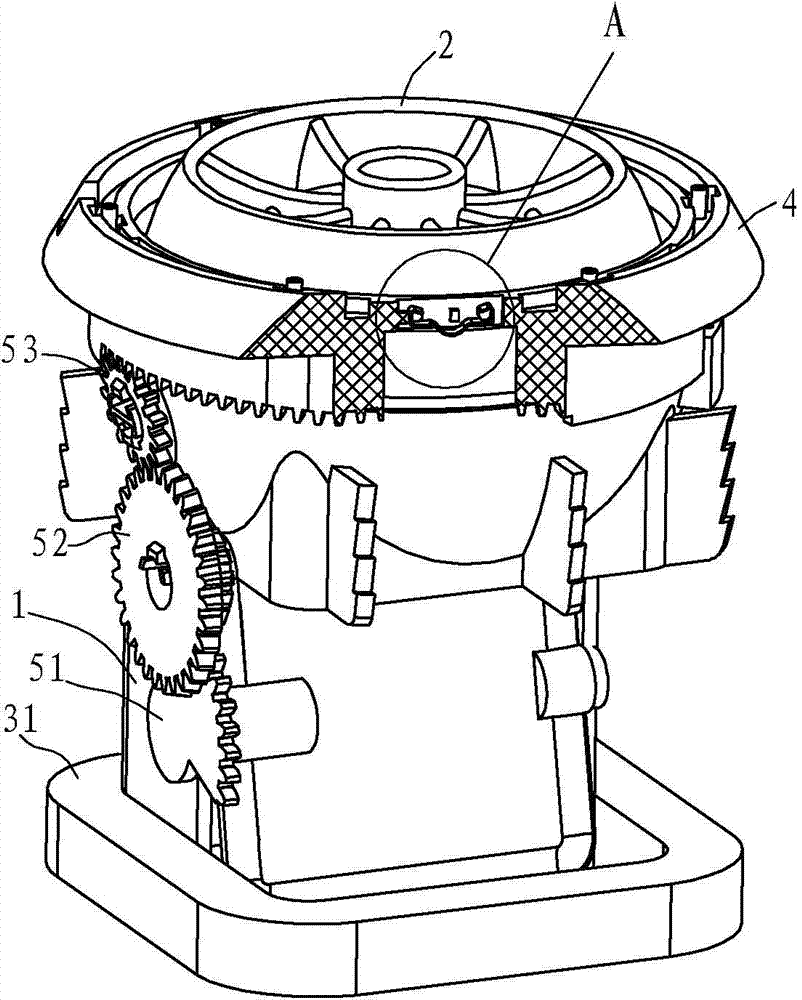

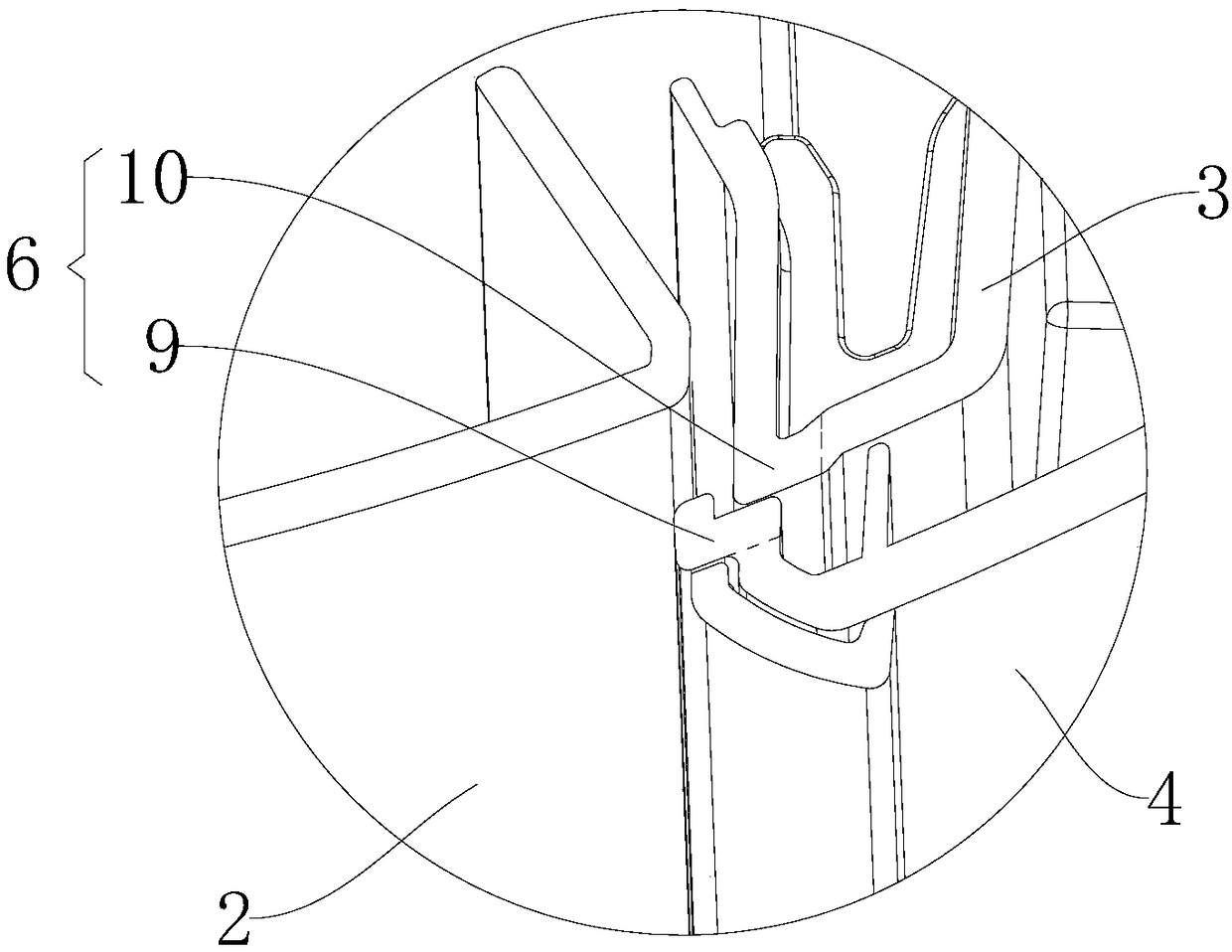

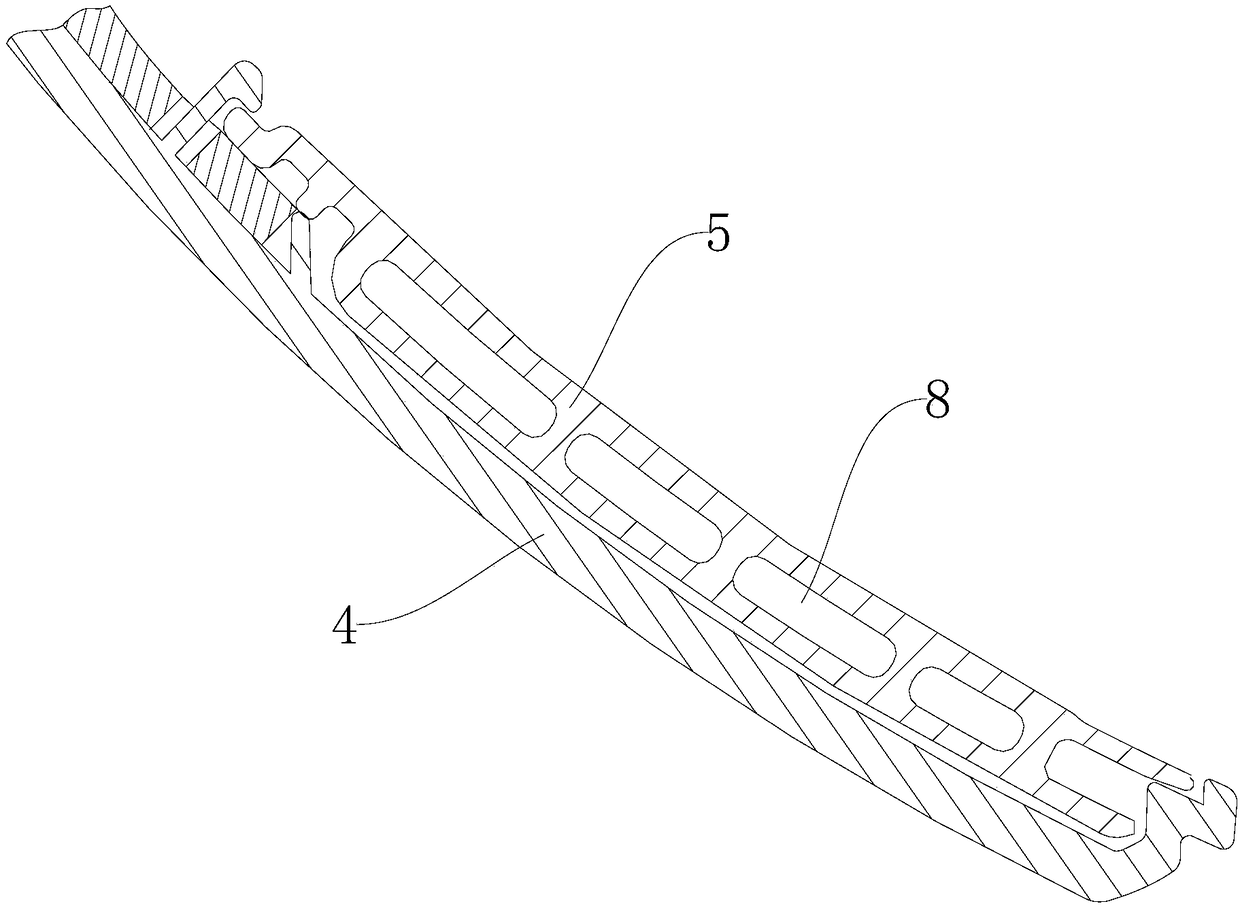

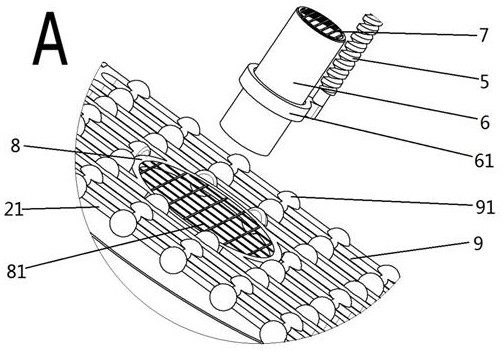

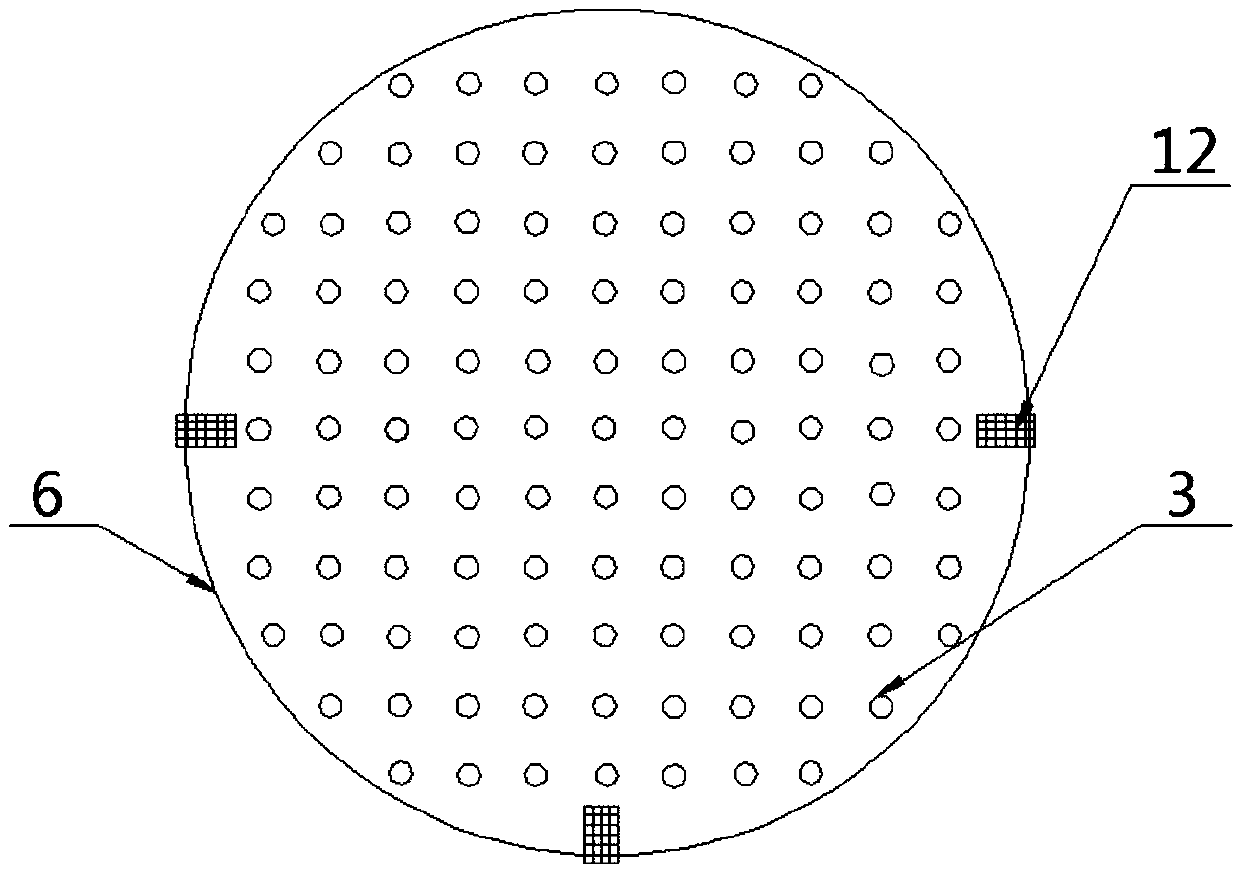

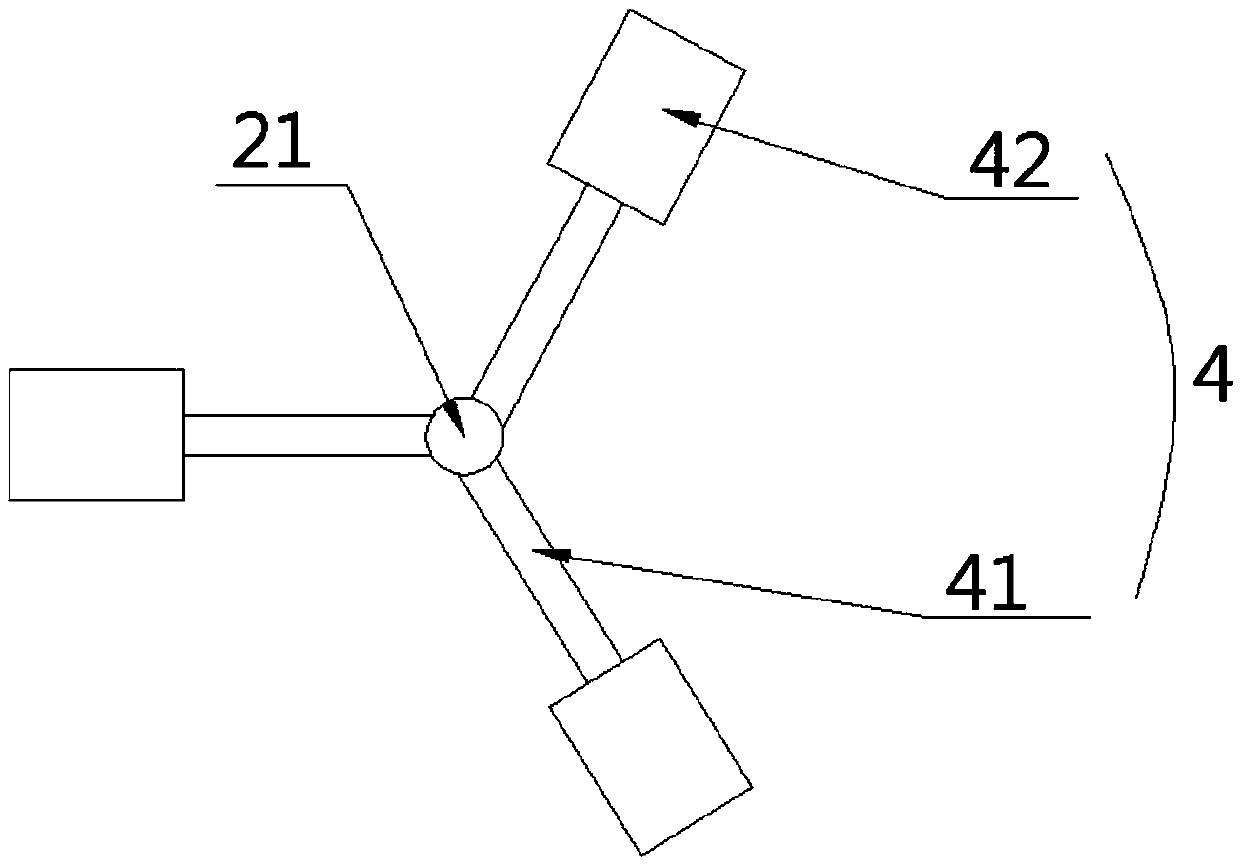

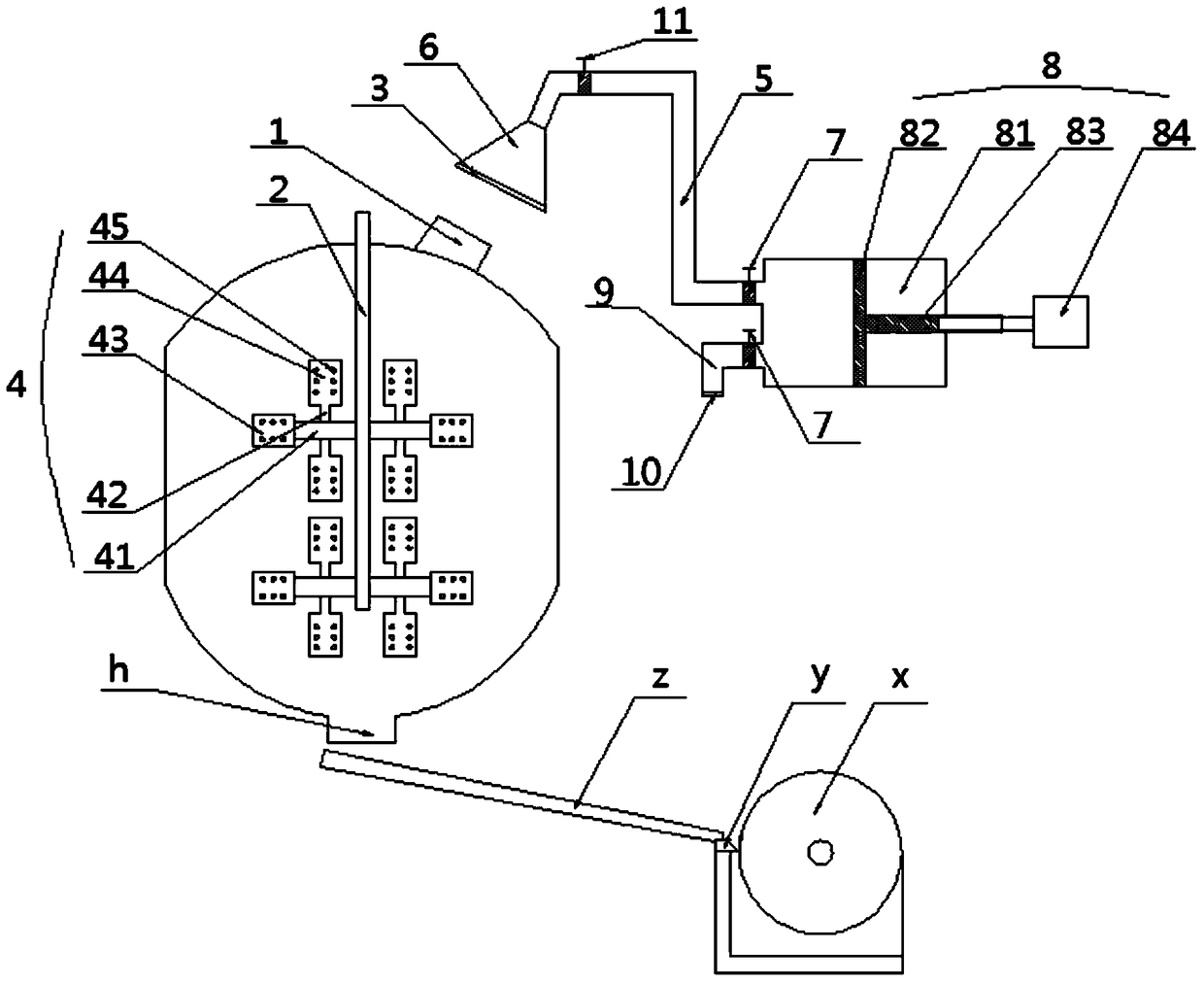

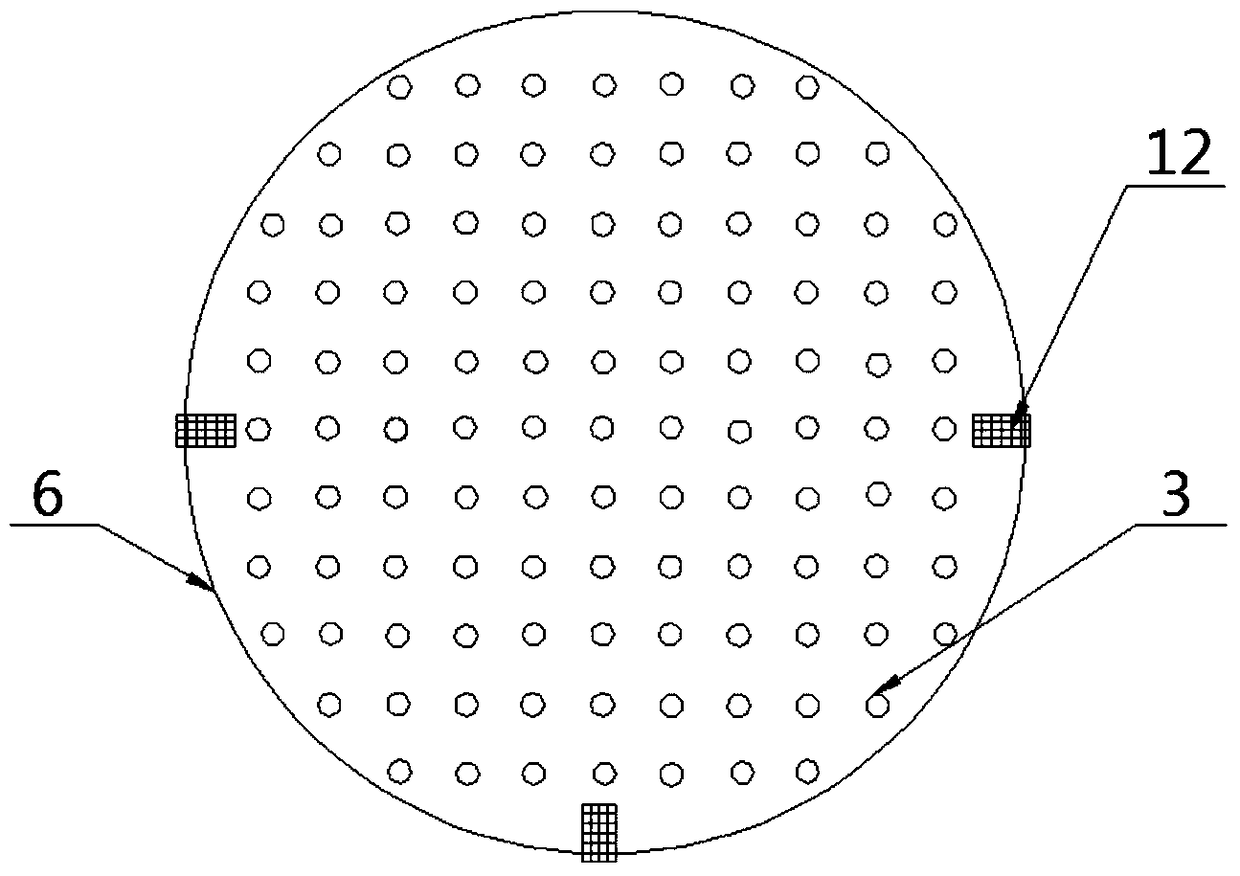

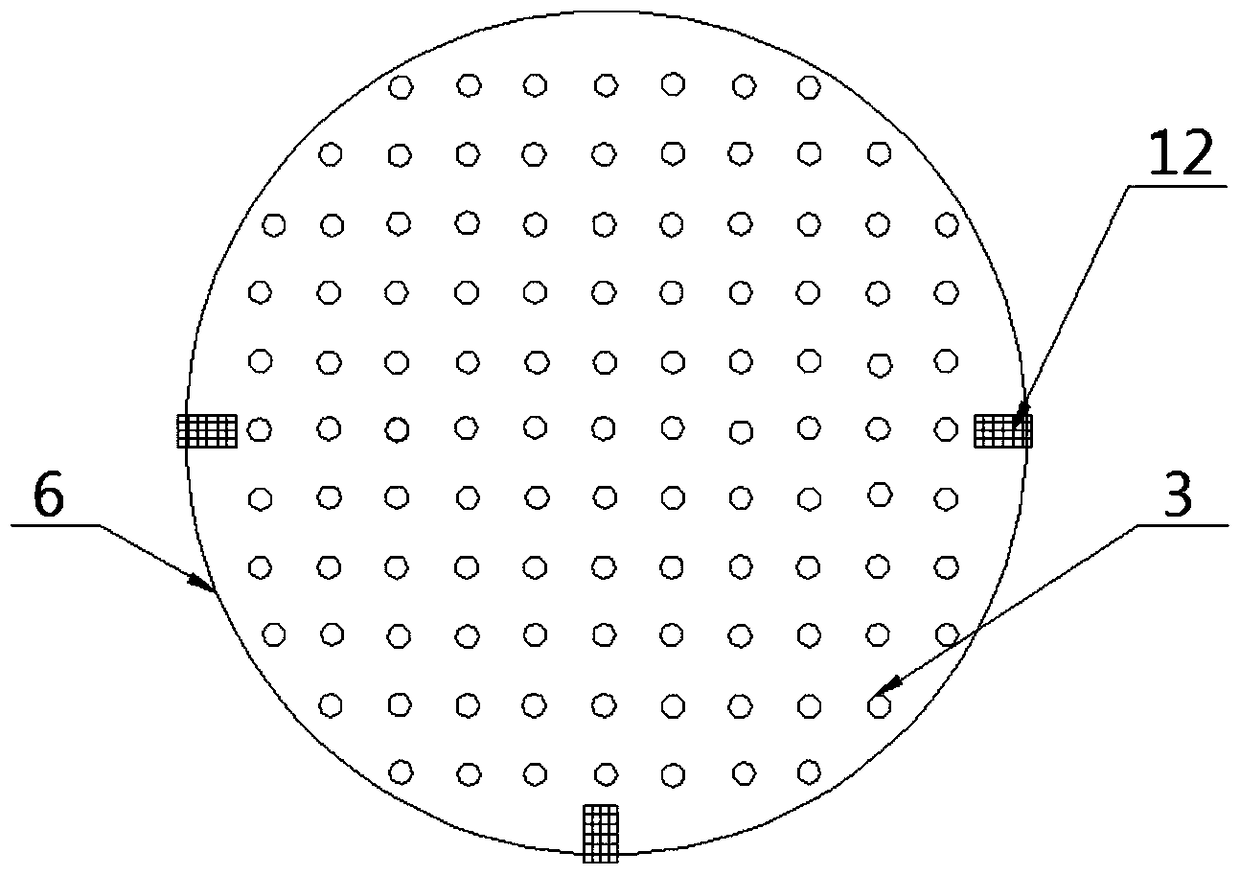

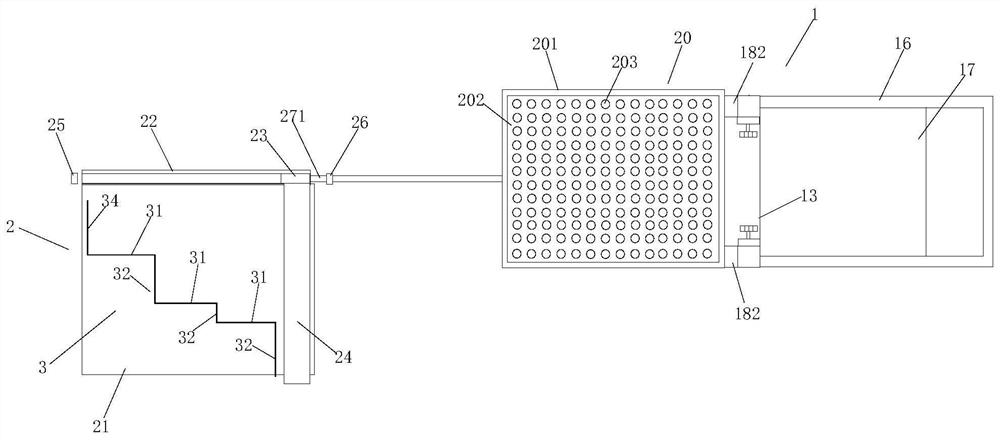

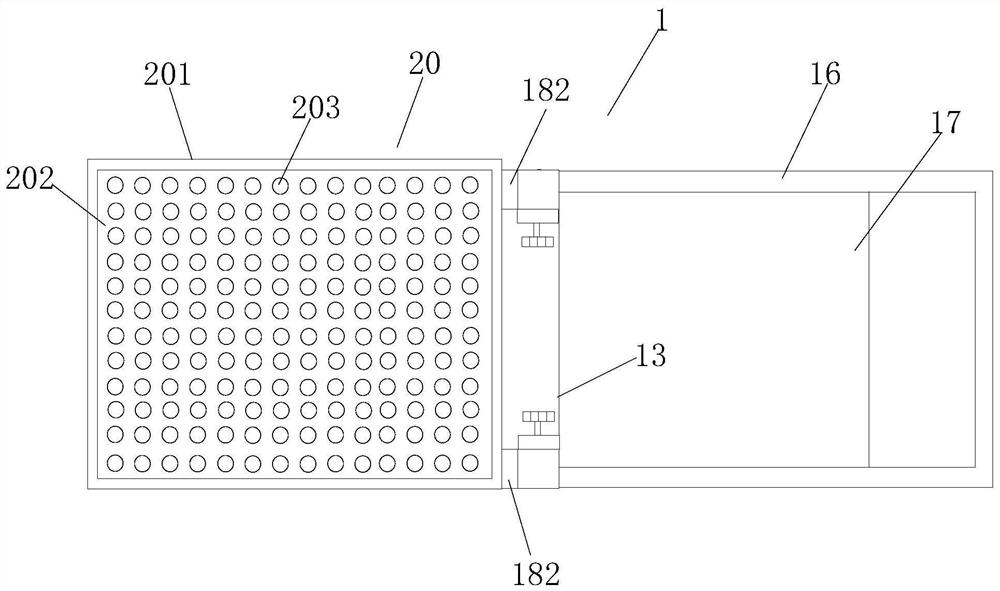

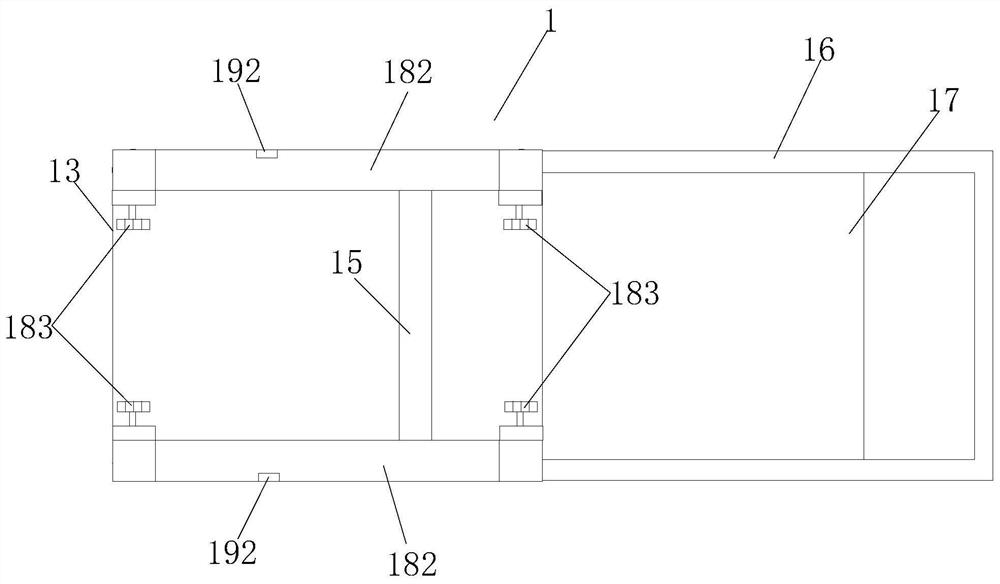

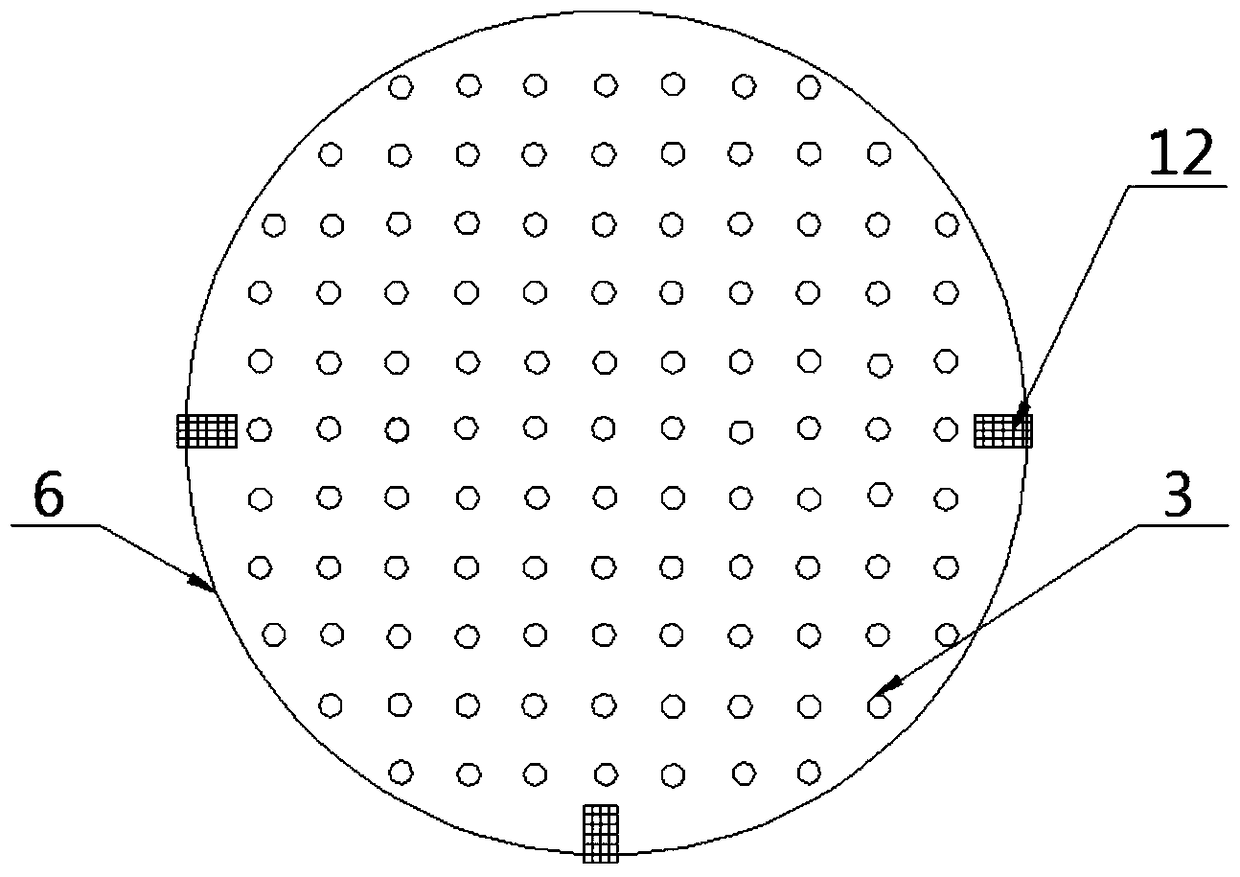

Vehicle air conditioner circular air outlet assembly

ActiveCN104729047AAdjust the size of the windSmall installation volumeAir-flow control membersGratingAutomobile air conditioning

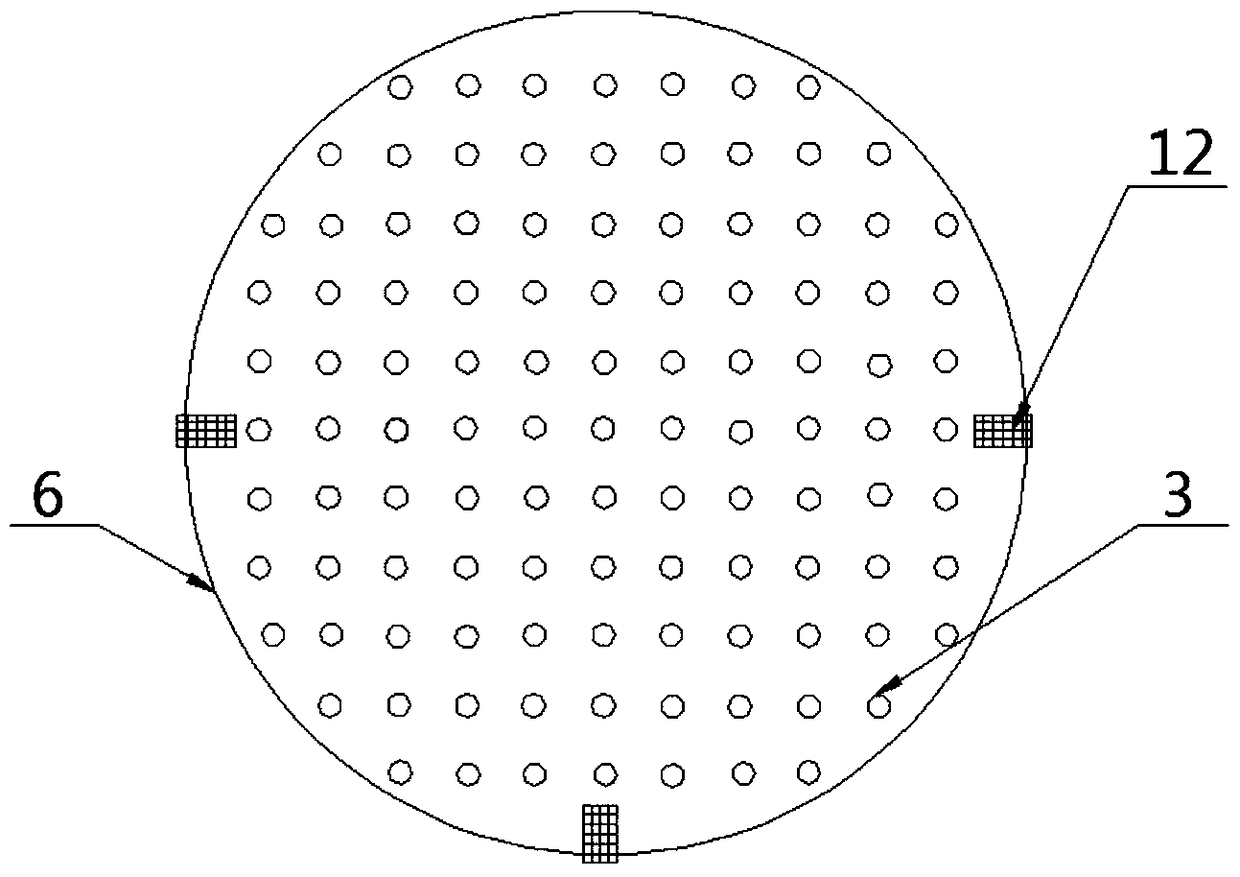

Provided is a vehicle air conditioner circular air outlet assembly. The vehicle air conditioner circular air outlet assembly comprises a shell, a spherical grating and a ventilation door. A front end opening of the shell is in the shape of a circle. The spherical grating is rotatably arranged on the front end opening of the shell. The ventilation door is arranged inside the shell and can be overturned through a driving mechanism. The vehicle air conditioner circular air outlet assembly is characterized in that the driving mechanism comprises a crank, an adjusting ring and a gear set, the crank is rotatably arranged on the outer wall of the shell, one end of the crank is exposed to form a fan-shaped gear, and the other end of the crank is connected with the ventilation door; the adjusting ring can rotatably arranged on the front end opening of the shell, the inner end is provided with gear teeth along the annular direction, the gear set is rotatably arranged on the outer wall of the shell, the output end of the gear set is engaged with the fan shape in a transmission mode, and the input end of the gear set is engaged with the gear teeth of the adjusting ring in a transmission mode. Compared with the prior art, the vehicle air conditioner circular air outlet assembly has the advantages that the adjusting ring and the shell are integrated together, the installing volume is greatly reduced, the overall structure is compact, and the operation is convenient.

Owner:NINGBO FUERDA SMARTECH CO LTD

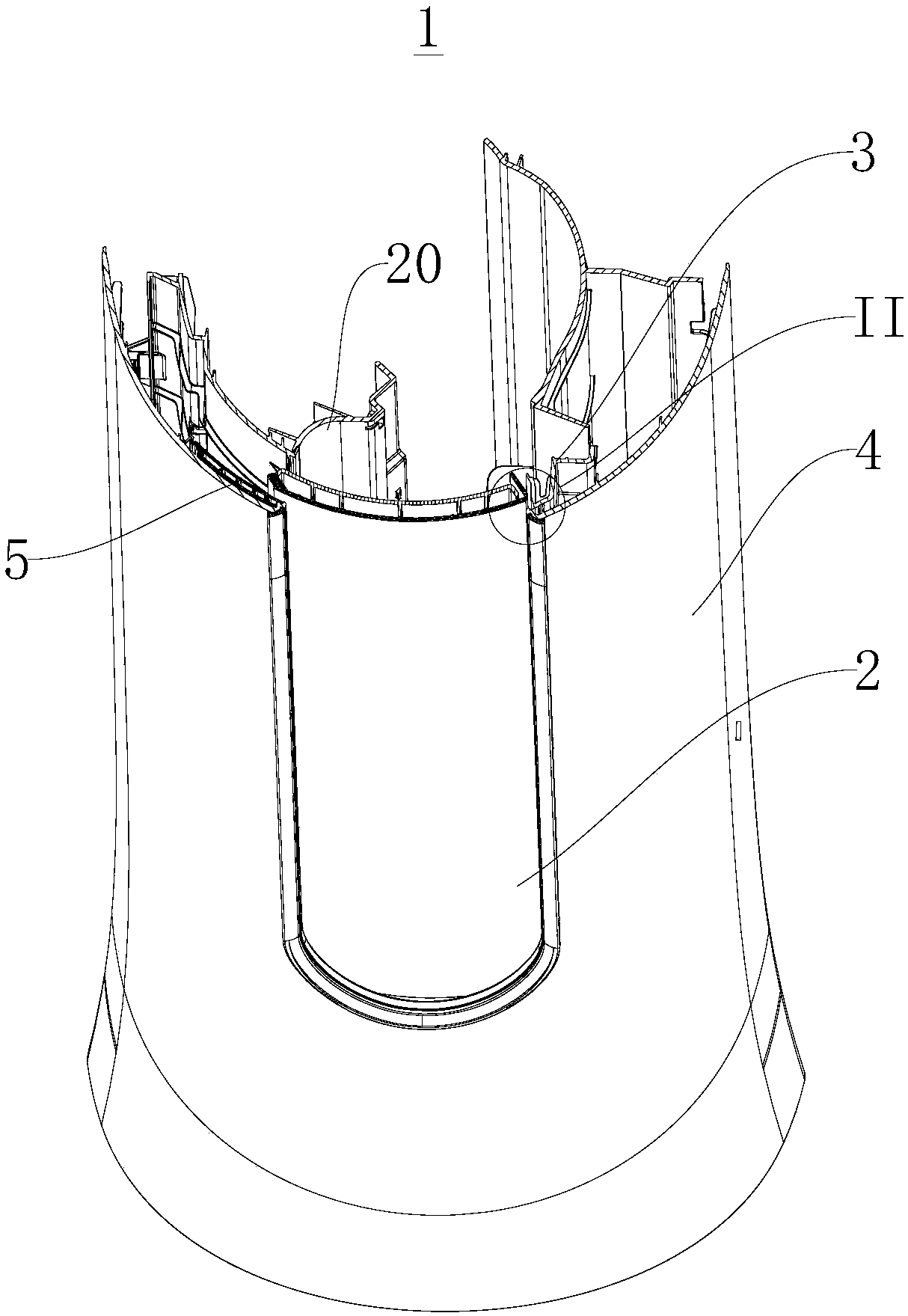

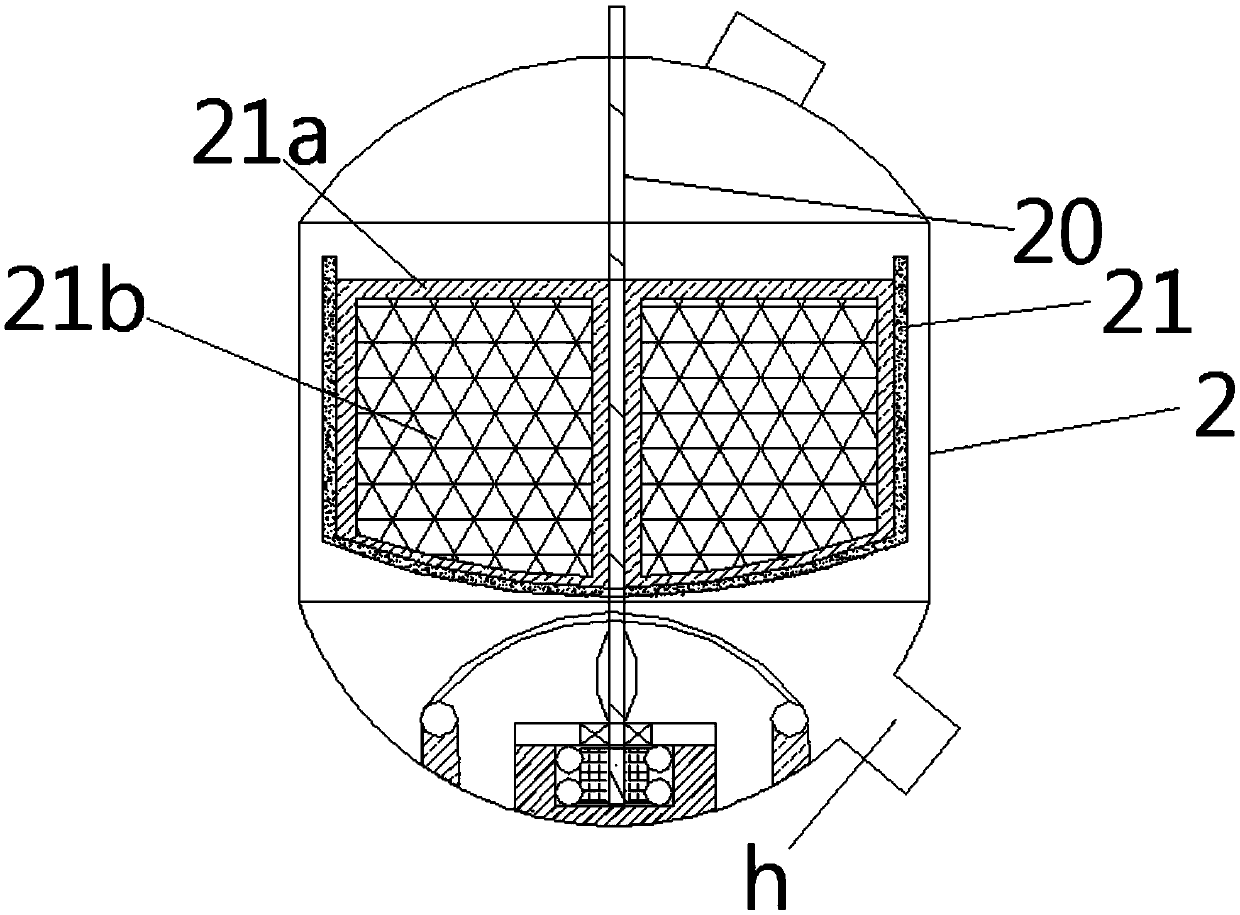

Condensation-prevention structure and air conditioner

ActiveCN108151272AAvoid enteringAvoid accessCondensate preventionHeating and ventilation casings/coversThermal insulationAerospace engineering

The invention provides a condensation-prevention structure and an air conditioner, and relates to the technical field of air conditioners. The condensation-prevention structure comprises a sliding door, a front panel lining plate, a front panel, a reinforcing plate and a first seam allowance assembly, an air opening is formed in the front panel, the front panel is installed on the front panel lining plate, and the sliding door is in sliding fit with the front panel lining plate; the reinforcing plate is detachably installed at the inner side, close to the air opening, of the reinforcing plate,and the reinforcing plate is provided with at least one through thermal insulation cavity. The first stopping seam allowance assembly is located at the other side, opposite to reinforcing plate, of the air opening, and comprises a first seam allowance part and a second seam allowance part, the first seam allowance part is arranged on the front panel, the second stop part is arranged on the frontpanel lining plate, and the first seam allowance part cooperates with the second seam allowance part to shield gaps between the front panel and the front panel lining plate. By means of the condensation-prevention structure, the condensation problem of the air conditioner can be solved, it is guaranteed that the front panel and the interior of the air conditioner are dry, then the service life ofthe air conditioner is prolonged, and the user experience is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

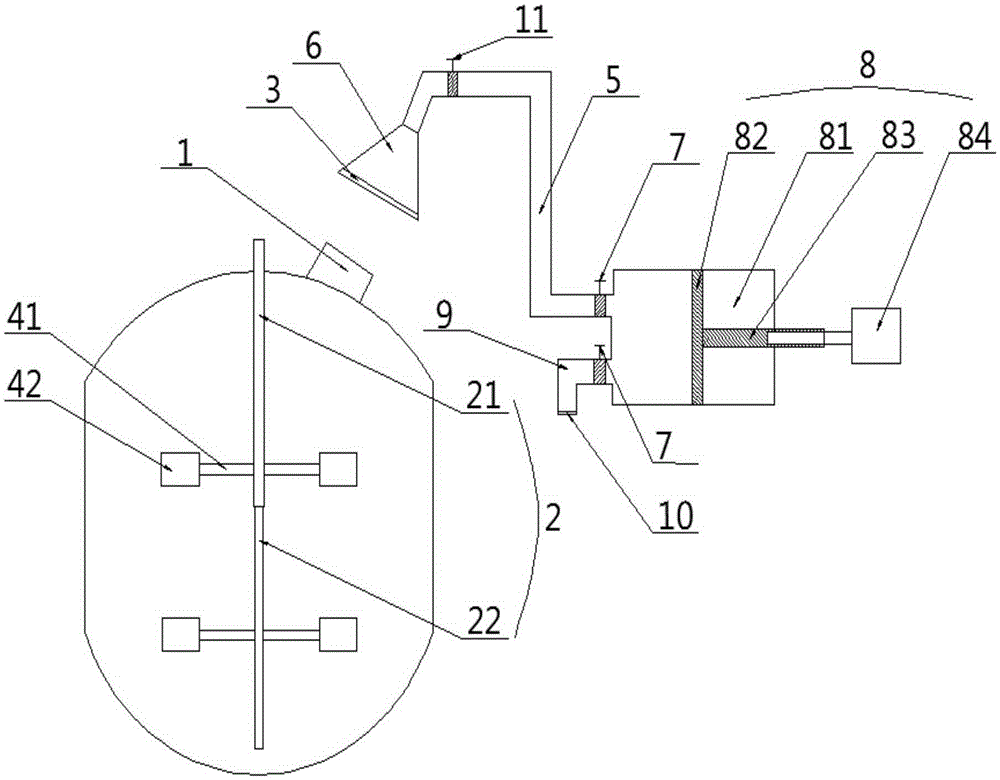

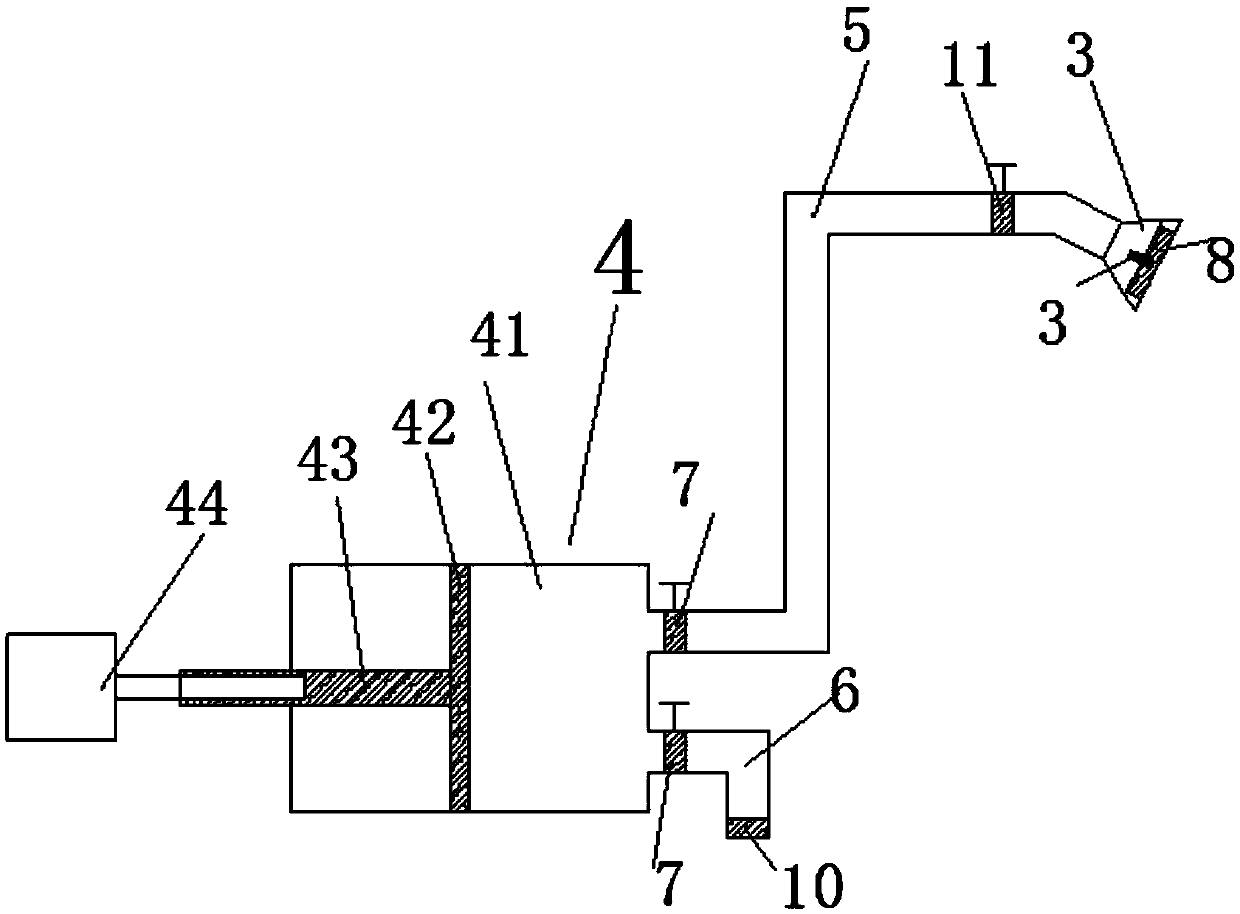

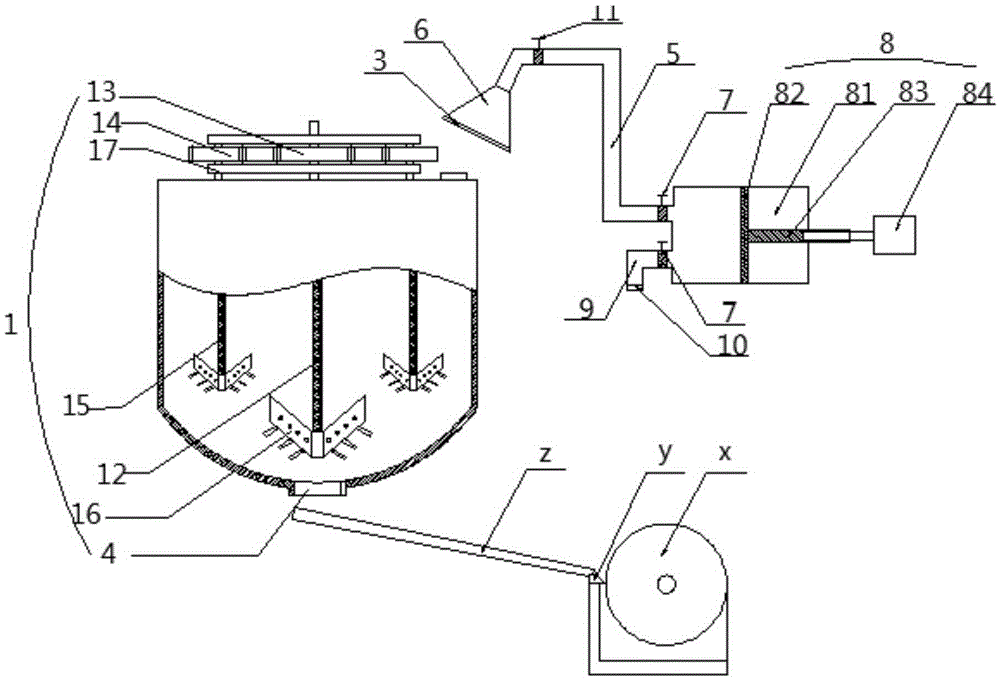

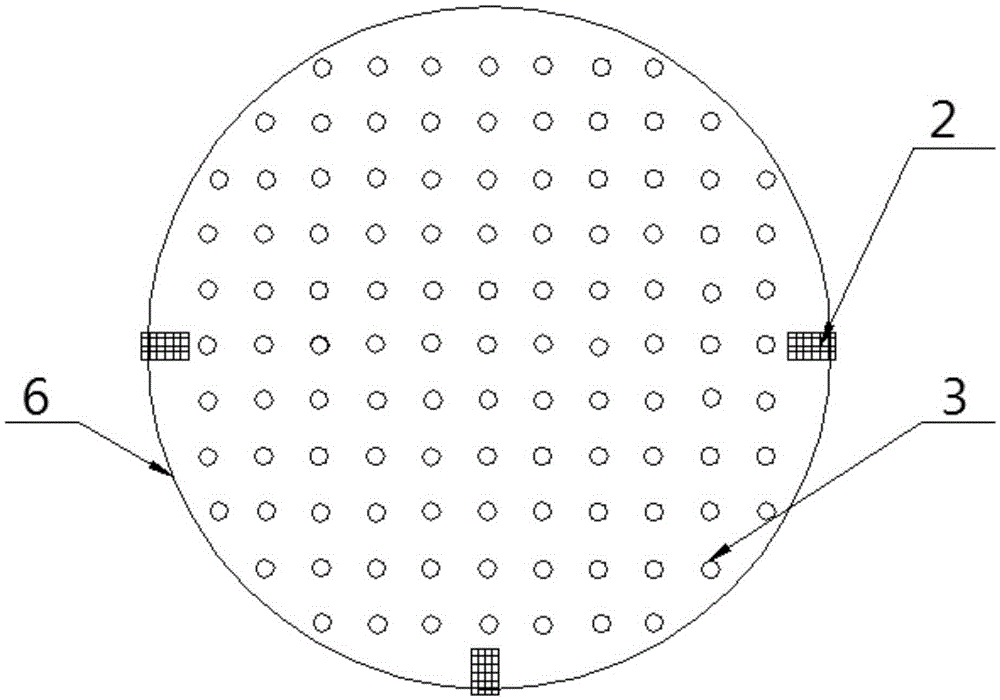

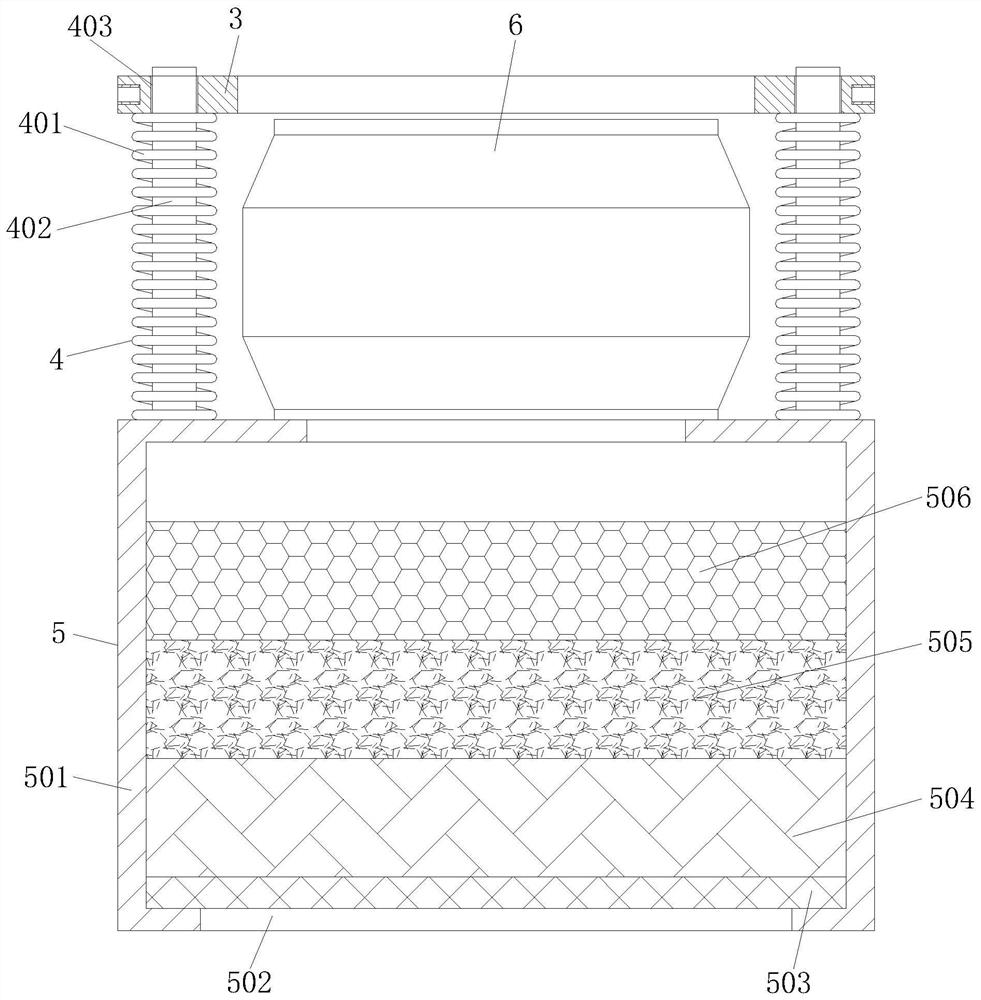

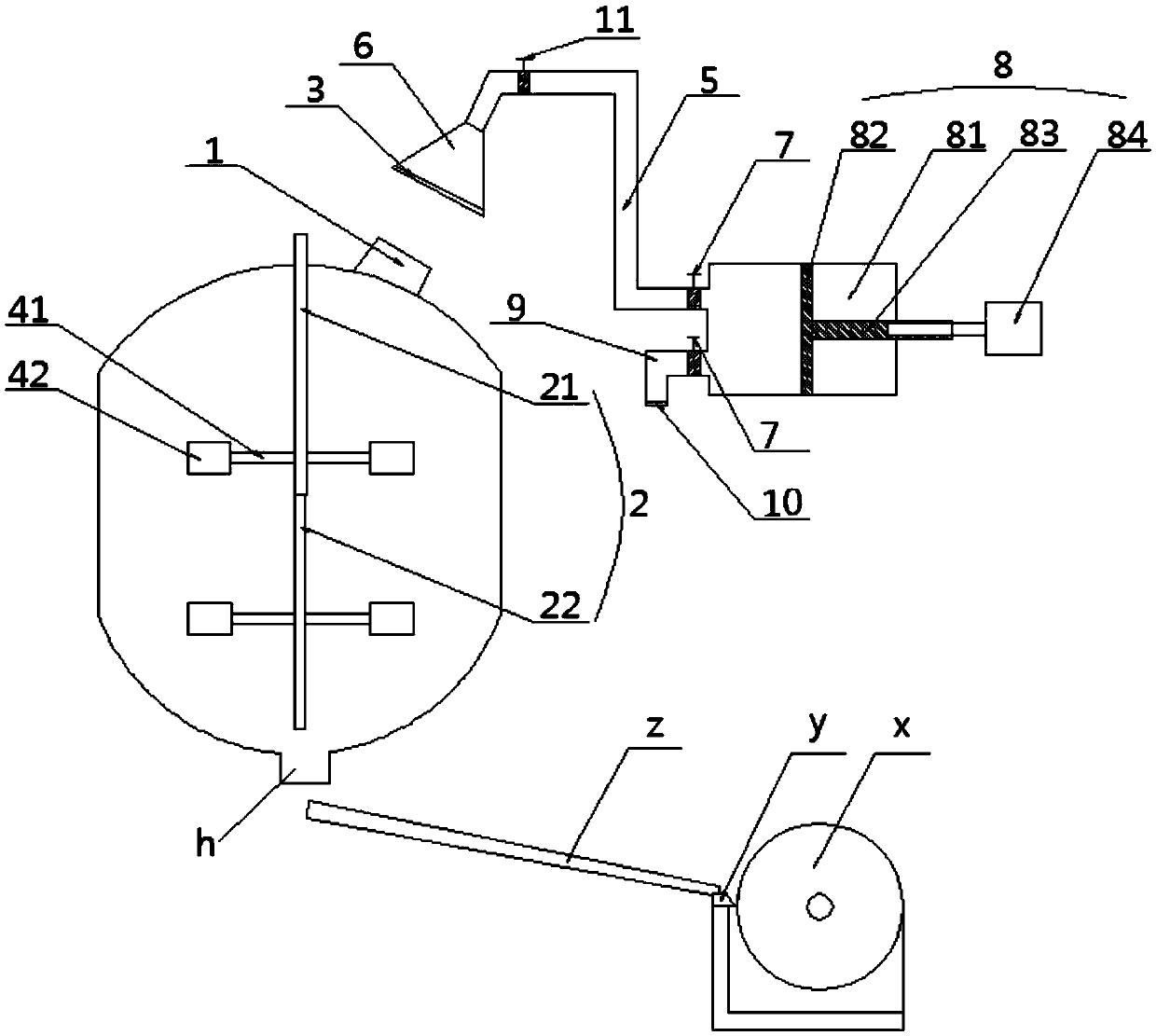

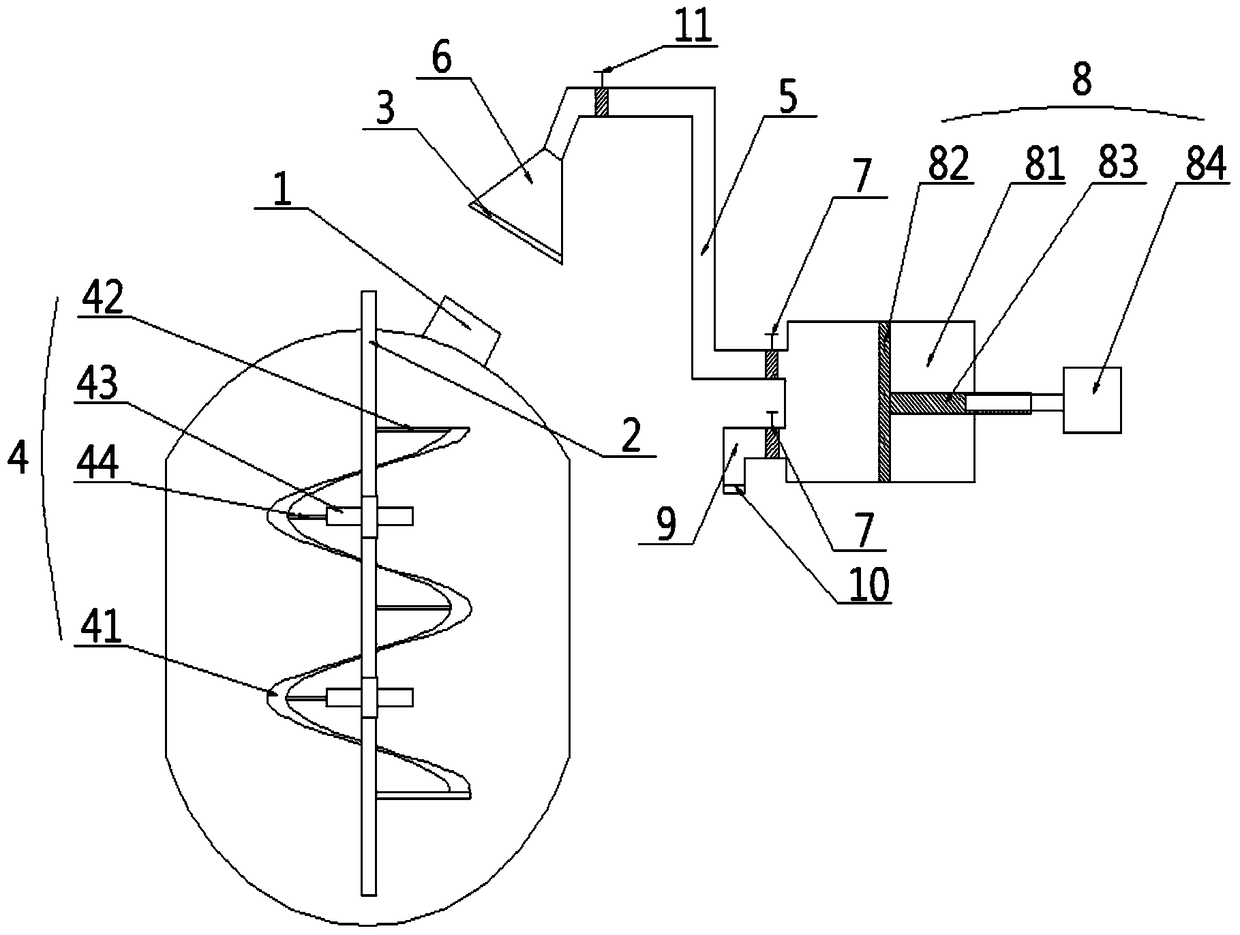

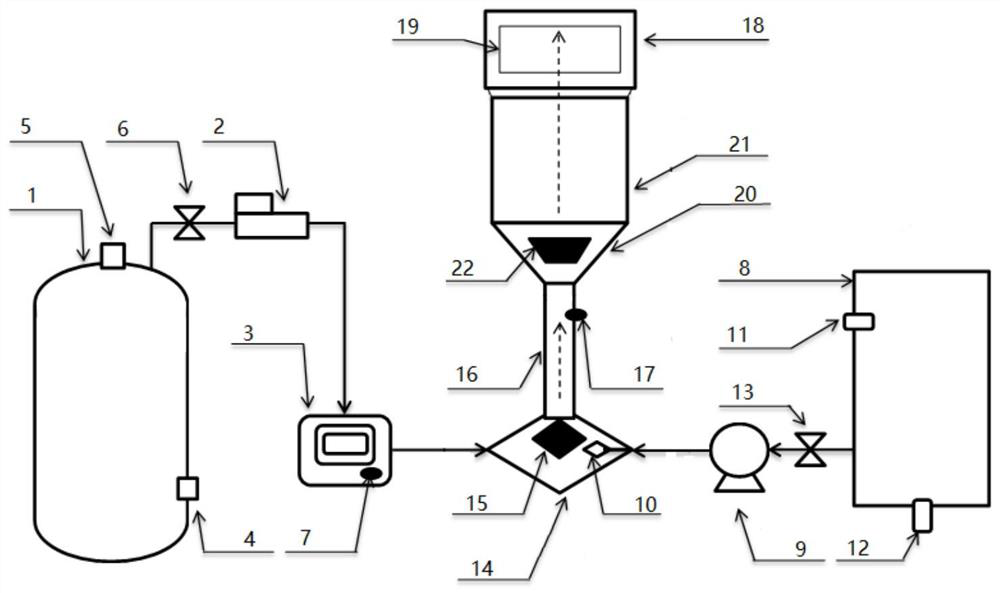

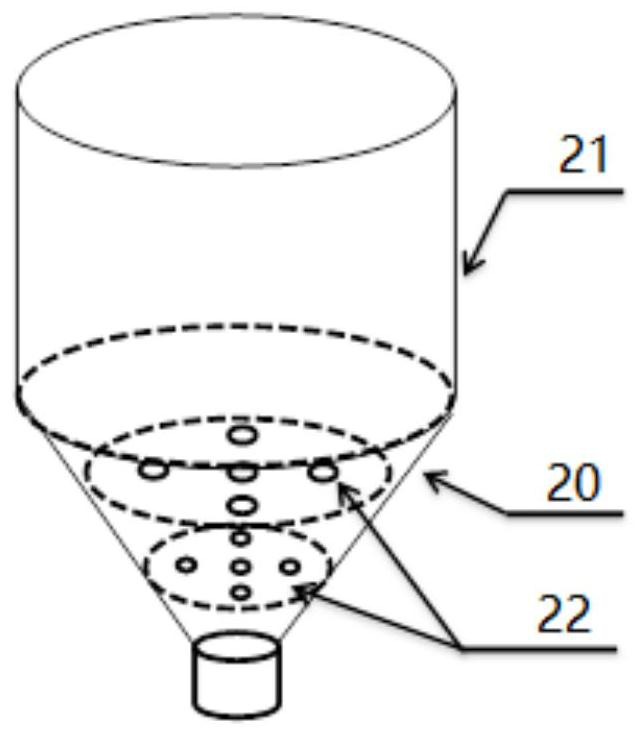

Novel dust collection reaction system

InactiveCN105344304AWell mixedImprove securityDispersed particle filtrationDirt cleaningPhysical well beingEngineering

The invention discloses a novel dust collection reaction system. The novel dust collection reaction system comprises a dust absorption device and a reaction kettle, wherein a feed opening is formed in the top of the reaction kettle; the dust absorption device comprises a suction hood and evacuating equipment; the suction hood is located above the feed opening and connected with the feed opening by a dust collection tube; the evacuating equipment comprises an evacuating cylinder with a piston arranged therein; the piston is connected with a piston rod; one end of the piston rod extends out from the rear end of the evacuating cylinder and is connected with a lead screw motor; a lead screw of the lead screw motor extends into the sleeve-shaped piston rod and is in threaded connection with the sleeve-shaped piston rod; a stirring main shaft is arranged in the reaction kettle and comprises a first main shaft and a second main shaft; the first main shaft is sleeve-shaped and movably sleeves the second main shaft; the upper ends of the first main shaft and the second main shaft respectively penetrate the reaction kettle; stirring paddles are respectively mounted on the first main shaft and the second main shaft. The novel dust collection reaction system can suck powdered raw materials floating at the feed opening in the feeding process and prevent the powdered raw materials from flying upwards, thereby guaranteeing the body health of workers and safety production of factories.

Owner:CHONGQING TAIYUE TECH

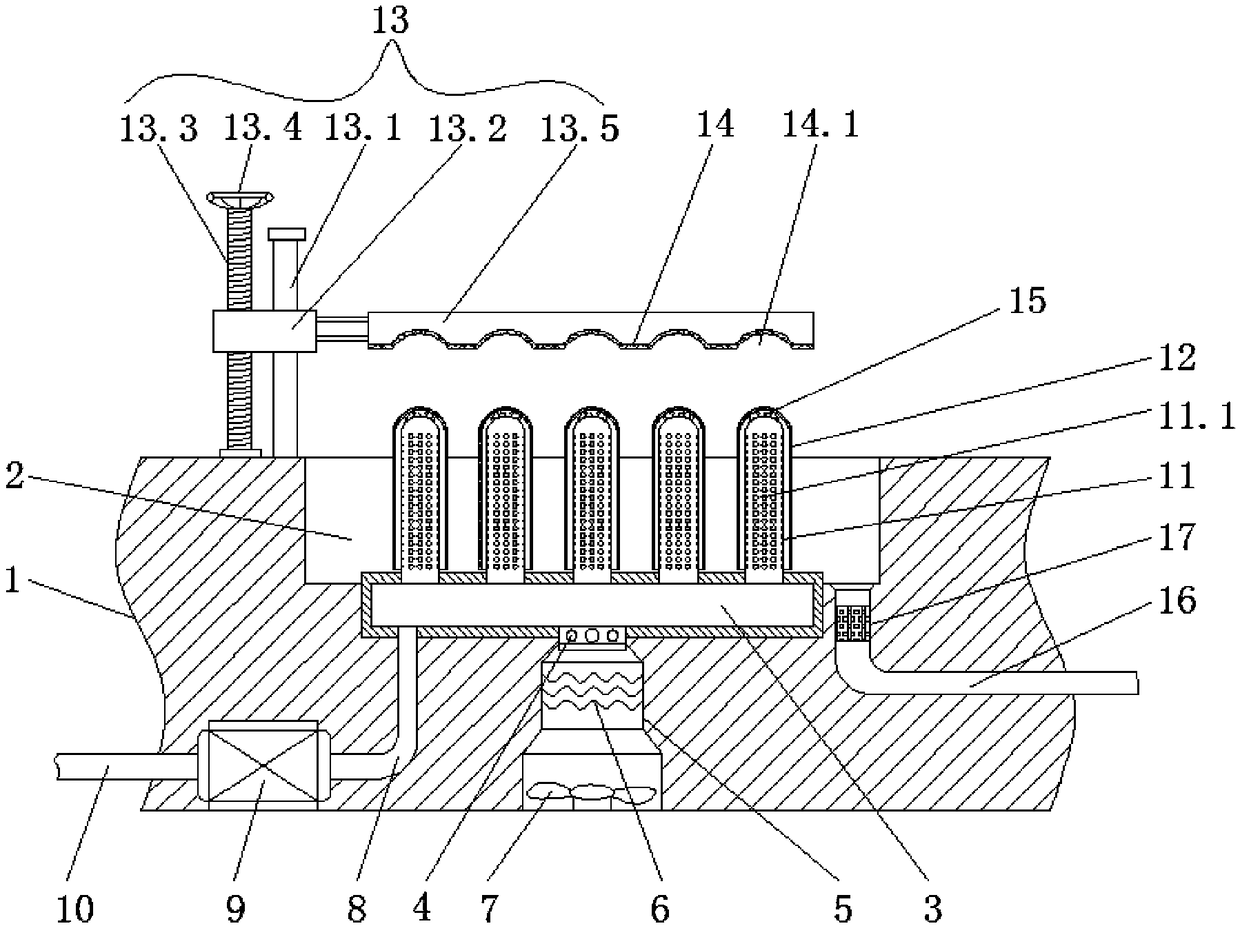

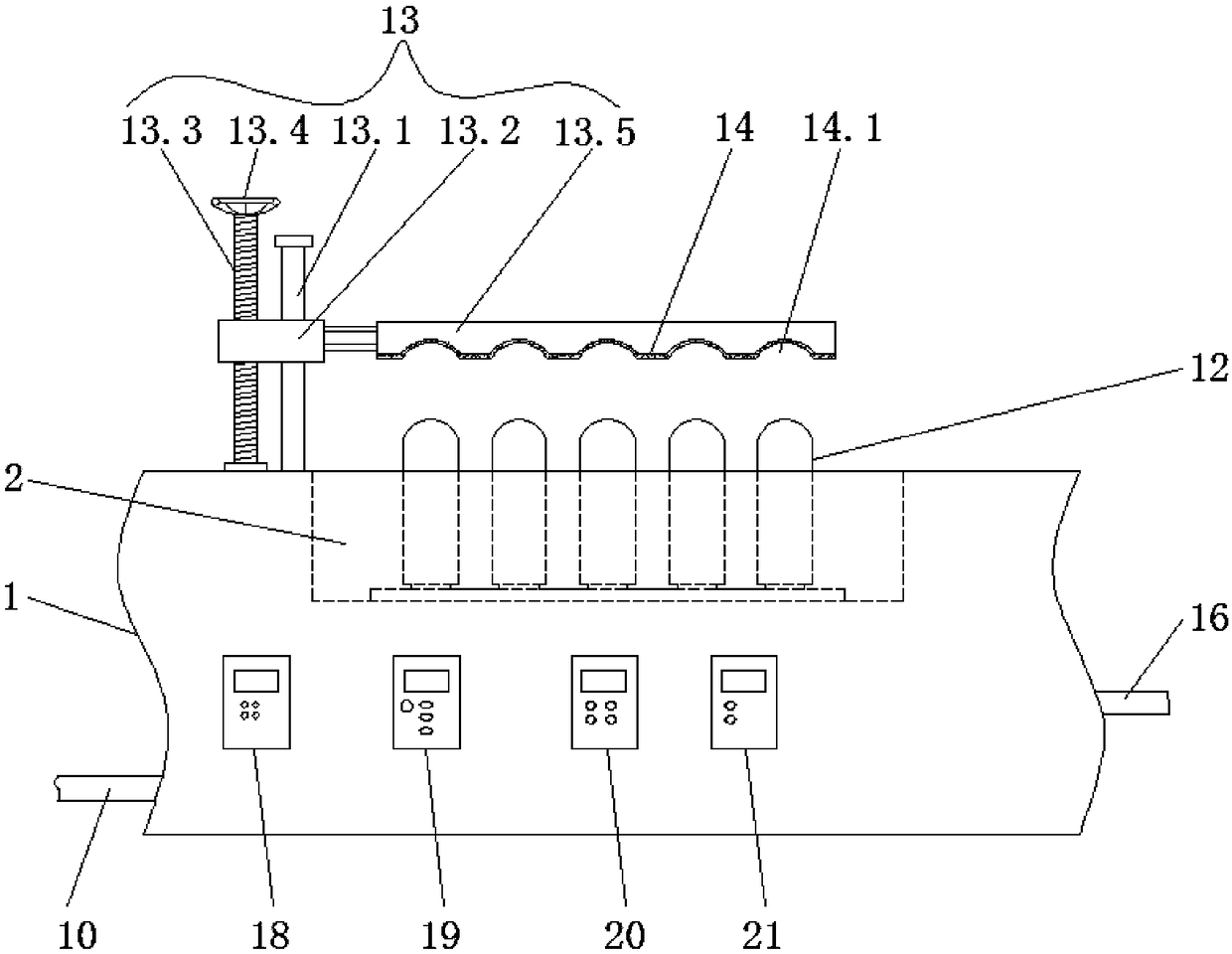

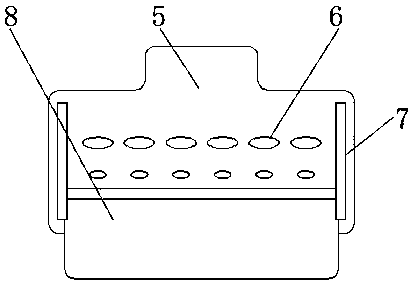

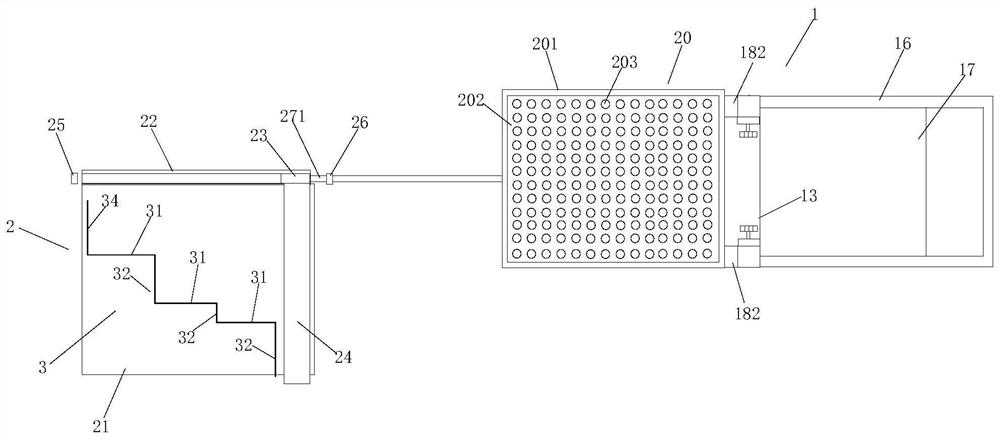

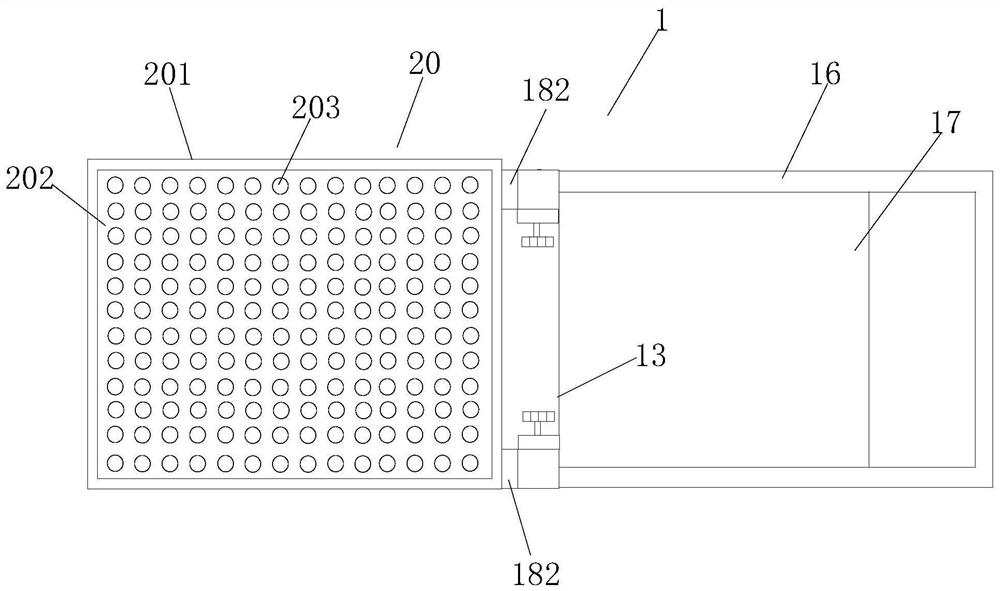

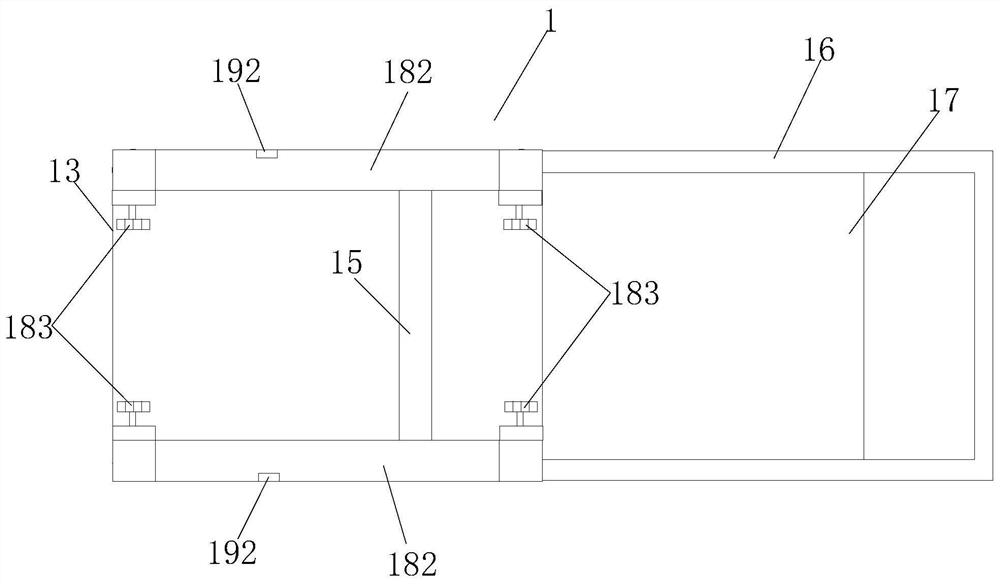

Integrated test tube cleaning experiment table for teaching

PendingCN109382149AQuick washPrevent looseningHollow article cleaningDrying gas arrangementsEngineeringWater pipe

The invention discloses an integrated test tube cleaning experiment table for teaching and relates to the technical field of teaching equipment. The experiment table comprises a cleaning table, wherein a cleaning tank is formed in the cleaning table, a cavity is formed in the inner bottom of the cleaning tank, the bottom of the cavity is connected with a valve, the valve is connected with a ventilation pipe, an electric heating wire is arranged in the ventilation pipe, the bottom of the ventilation pipe is connected with a fan, the bottom of the cavity is connected with a first water pipe connected with a water pump, the water pump is connected with a second water pipe, a plurality of hollow columns communicated with the cavity and used for hanging test tubes upside down are connected withthe top of the cavity, through holes communicated with the inner cavities of the hollow columns are formed in the hollow columns, and a limit clamping mechanism for tightly pressing the test tubes isarranged in a position, close to the cleaning tank, of the cleaning table. The experiment table has the advantages of being simple in structure, high in practicability and capable of cleaning and drying the test tubes once and shortening reuse time.

Owner:大竹县庙坝中学

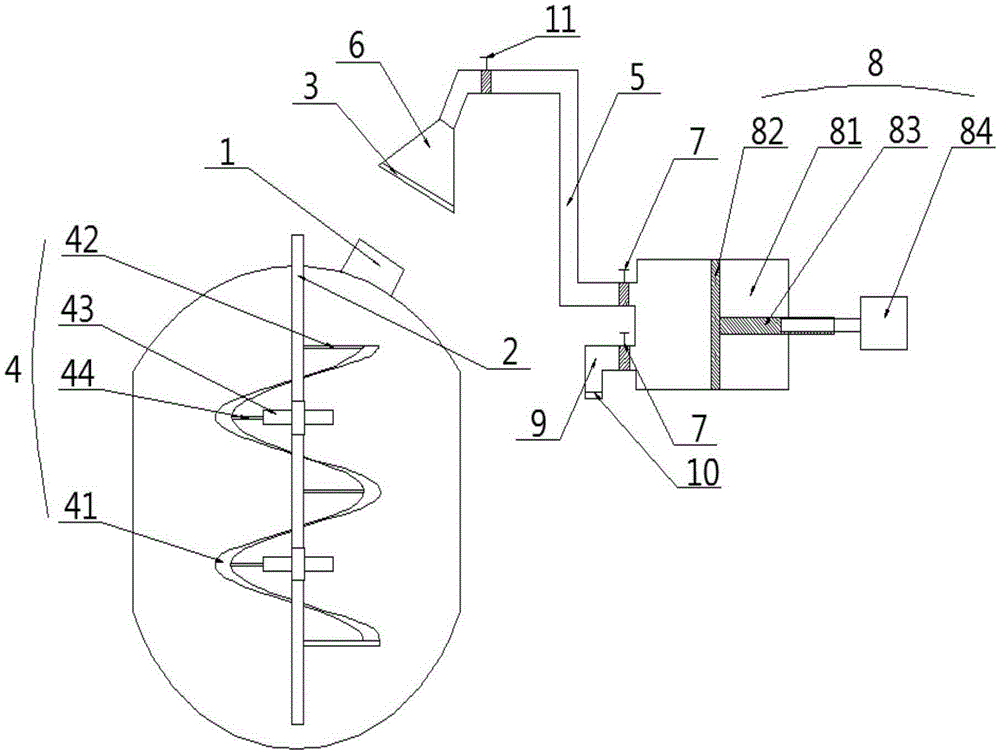

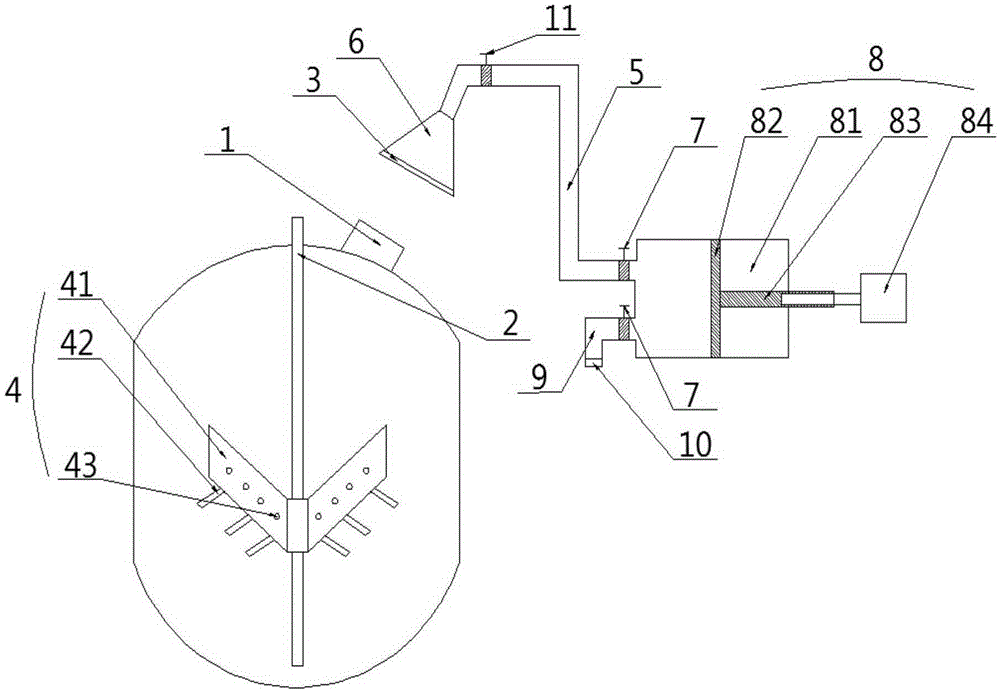

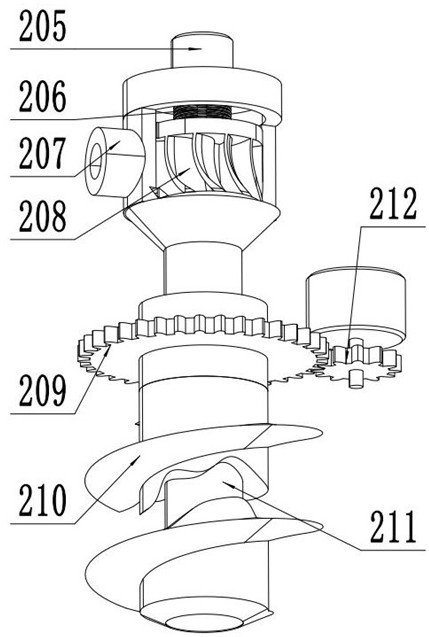

Dust collection reaction system with combined stirring paddle

ActiveCN105344305AAvoid flyingKeep healthyDispersed particle filtrationRotary stirring mixersEngineeringTurbine

The invention discloses a dust collection reaction system with a combined stirring paddle. The dust collection reaction system comprises a dust collection device and a reaction still, wherein a feeding opening is formed in the top of the reaction still; the dust collection device comprises a dust hood positioned above the feeding opening and a suction device; the dust hood and the suction device are connected through a dust collection pipe; the suction device comprises a suction pump in which a piston is arranged; the piston is connected with a piston rod; one end of the piston rod extends out of the rear end of the suction pump and is connected with a screw rod motor; a screw rod of the screw rod motor extends into the sleeve-shaped piston rod and is in threaded connection with the piston rod; a stirring main shaft is arranged in the reaction still; the upper end of the stirring main shaft extends out of the reaction still; the stirring paddle is arranged on the stirring main shaft, and comprises a helix ribbon type stirring vane and turbine type stirring vanes. Through the adoption of the system, in a feeding process, powdery raw materials floating at the feeding opening can be sucked, so that flying of the powdery raw materials is avoided, and body health of workers and safety production of factories are ensured.

Owner:CHONGQING TAIYUE TECH

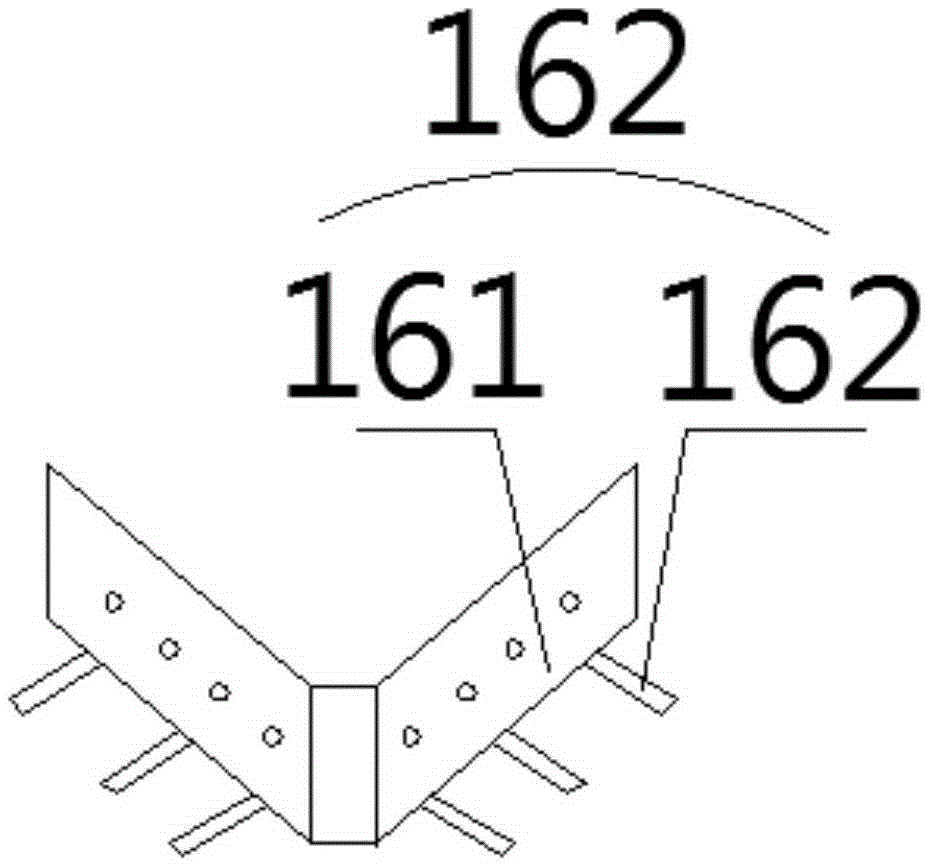

Dust collecting reaction system with stirring device

InactiveCN105396539AWell mixedImprove securityGas treatmentDispersed particle filtrationEngineeringReaction system

The invention discloses a dust collecting reaction system with a stirring device. The dust collecting reaction system with the stirring device comprises a dust collecting device and a reaction kettle. A feeding port is formed in the top of the reaction kettle. The dust collecting device comprises a dust collecting cover and an air extractor. The dust collecting cover is located above the feeding port. The dust collecting cover and an air extracting device are connected through a dust collecting pipe. The air extractor comprises an air extracting barrel internally provided with a piston. The piston is connected with a piston rod. One end of the piston rod stretches out of the rear end of the air extracting barrel and is connected with a screw motor. A lead screw of the screw motor stretches into the sleeve-shaped piston rod and is in threaded connection with the piston rod. A stirring main shaft is arranged in the reaction kettle. The upper portion of the stirring main shaft stretches out of the reaction kettle. The stirring main shaft is provided with a stirring paddle which comprises V-shaped stirring blades, and stirring side sheets are arranged on the lower sides of the stirring blades. The dust collecting reaction system can extract powdery raw materials floating on the feeding port, the powdery raw materials are prevented from flying, and body health of workers and safe production of a factory are guaranteed.

Owner:CHONGQING TAIYUE TECH

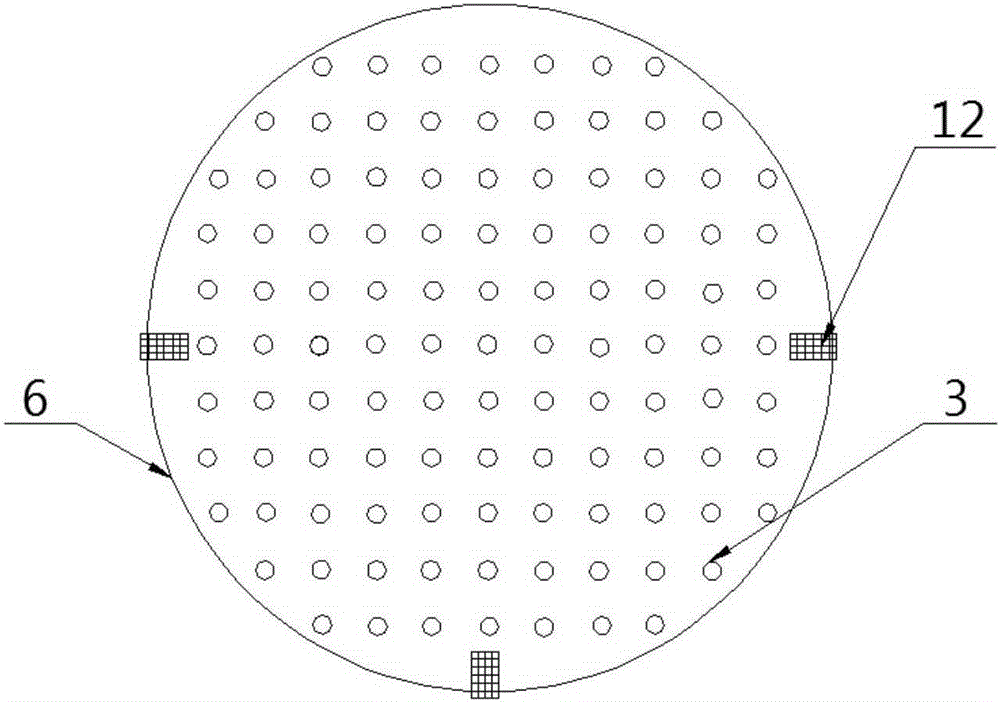

PVC stabilizer cut-off vane system

InactiveCN105498667ANo pollutionCan adjust the size of the windDispersed particle filtrationTransportation and packagingMechanical engineeringRaw material

The invention discloses a PVC stabilizer cut-off vane system, comprising a dust suction device, a reaction kettle and a cut-off vane machine. The reaction kettle is provided with a charging port in the top and a discharging port in the bottom, the cut-off vane machine is provided with a storage disk, the cut-off vane machine is located below the reaction kettle, the reaction kettle and the cut-off vane machine are connected by a flow guide chute of which the upper end is positioned below the discharging port, the lower end of the flow guide chute is positioned above the storage disk; the reaction kettle comprises a spiral stirring paddle and a limiting column; the dust suction device comprises a dust suction hood and an air extractor which are connected by a dust suction pipe; the dust suction hood is positioned above the charging port; the reaction kettle comprises a stirring shaft provided with a stirring paddle and a slave paddle is mounted between the stirring paddle and the stirring shaft. The PVC stabilizer cut-off vane system has the beneficial effects that by the dust suction device, dust generated during charging is adsorbed to the dust suction hood, raw materials are recycled by a filter net, and the filter net on a dust discharging pipe can discharge clean gas without polluting environment.

Owner:CHONGQING TAIYUE TECH

Multi-blade stirring-type dust collecting reaction system

InactiveCN105344306AAvoid flyingKeep healthyDispersed particle filtrationDirt cleaningPhysical well beingEngineering

The invention discloses a multi-blade stirring-type dust collecting reaction system which comprises a dust collecting device and a reaction kettle, wherein a feeding opening is formed in the top of the reaction kettle; the dust collecting device comprises a dust collecting cover and an air suction device; the dust collecting cover is positioned above the feeding opening; the dust collecting cover and the air suction device are connected through a dust collecting pipe; the air suction device comprises an air suction cylinder in which a piston is arranged; the piston is connected with a piston rod; one end of the piston rod stretches out from the back end surface of the air suction cylinder and is connected with a screw rod motor; a screw rod of the screw rod motor stretches into the sleeve-shaped piston rod, and is in threaded connection with the piston rod; one end of the dust collecting pipe is connected with the front end surface of the air suction cylinder; a stirring main shaft is arranged in the reaction kettle; the upper part of the stirring main shaft stretches out of the reaction kettle; at least one set of stirring paddles is mounted on the stirring main shaft. Powdery raw materials floating at the feeding opening in the feeding process can be sucked, powdery raw material flying can be avoided, and health of workers and safe production of a factory can be ensured.

Owner:CHONGQING TAIYUE TECH

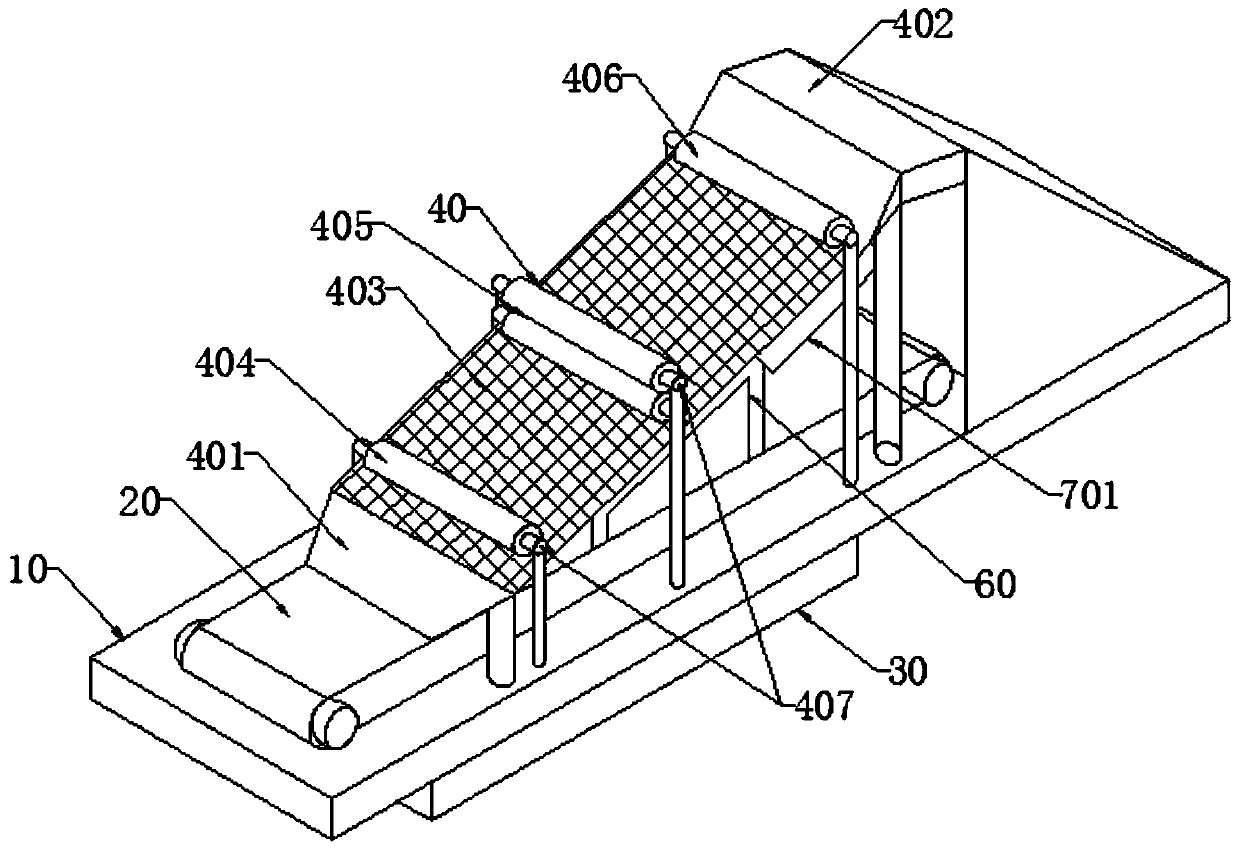

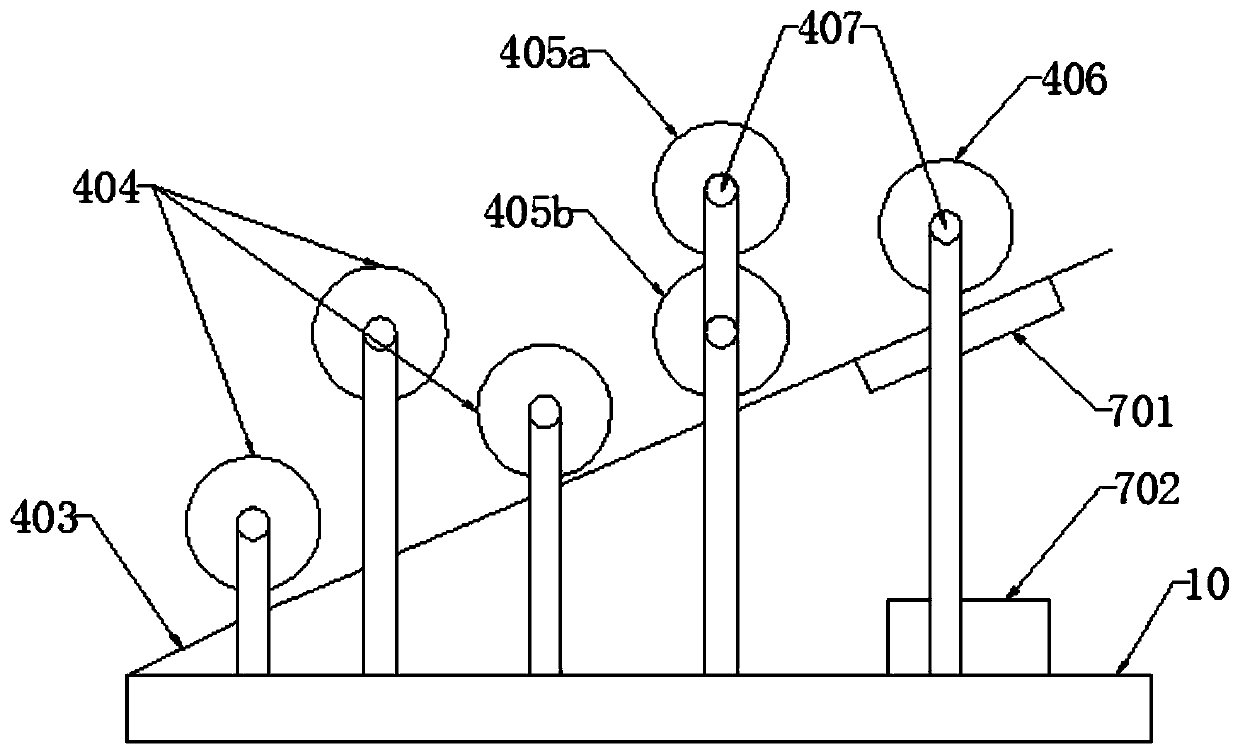

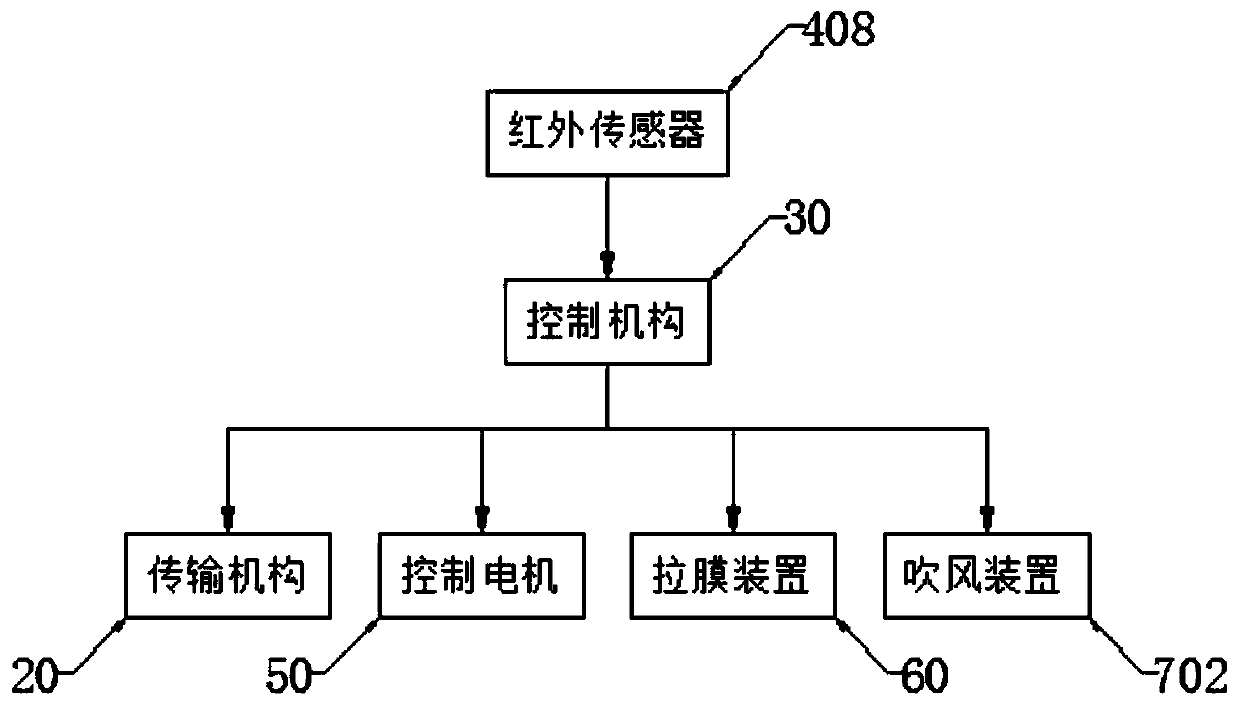

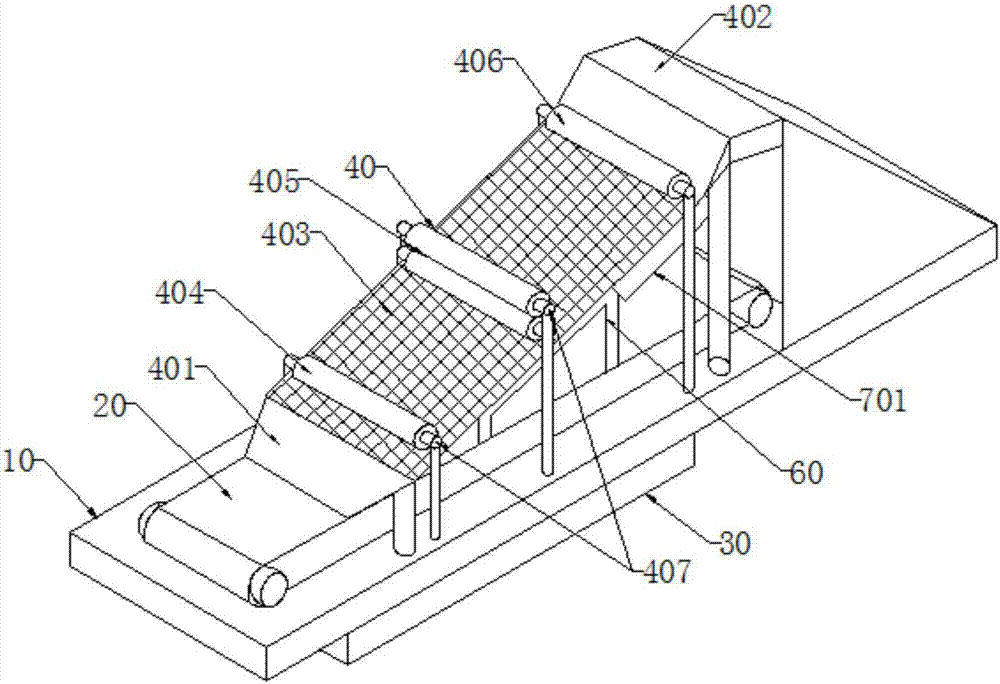

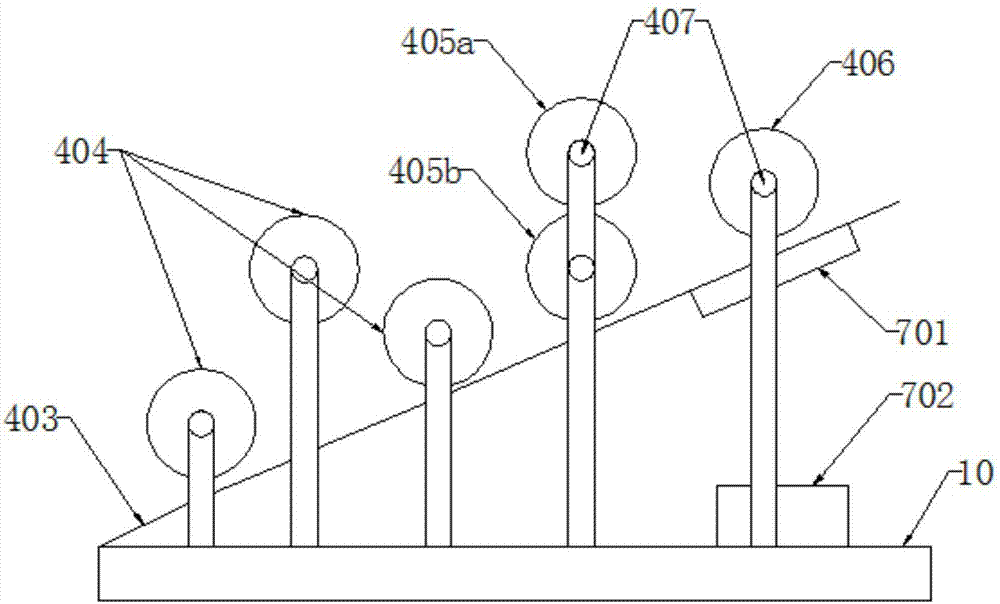

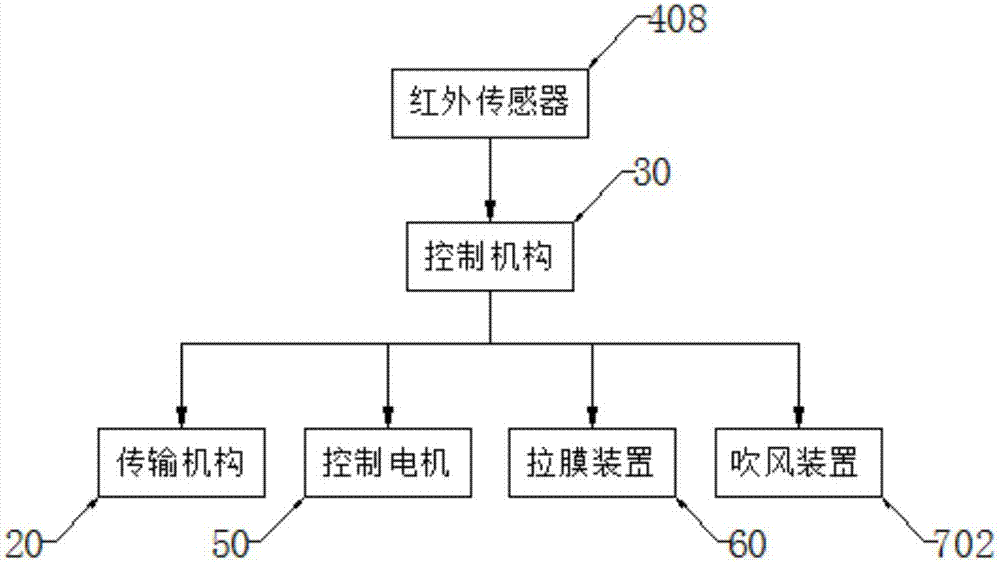

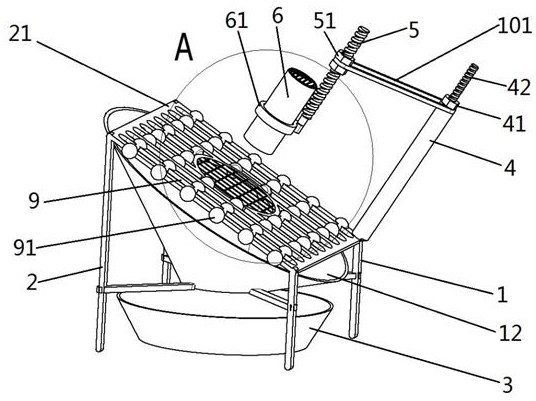

Film covering device and film covering method thereof

ActiveCN107972914BSimple structureEasy to useWrapping material feeding apparatusWebs handlingAgricultural engineeringFilm-coated tablet

The invention discloses a film coating device which comprises a base, a transmission mechanism arranged above the base, a control mechanism arranged below the base and a film coating mechanism arranged above the transmission mechanism, wherein the film coating mechanism comprises a feeding hole, a discharging hole, a film placement plate, a planishing roller, a film coating roller and an auxiliarycooling roller; the film placement plate is positioned between the feeding hole and the discharging hole and has an upward dip angle of 45-60 degrees; the planishing roller, the film coating roller and the auxiliary cooling roller are sequentially positioned above the film placement plate; two transmission rollers are arranged on two sides of each of the planishing roller, the film coating rollerand the auxiliary cooling roller; the transmission rollers are externally connected with a control motor; and the control mechanism controls and is connected with the transmission mechanism and the control motor. The invention further discloses a film coating method of the film coating device. The film coating device can realize automatic film coating to reduce the labor cost, can adjust the filmcoating direction and time, tightens the coated film, realizes a stagger planishing process to enable the films to be level and smooth enough and unified in structure and meet various production demands and improves the production efficiency and the film coating quality.

Owner:温州市创新晶彩科技有限公司

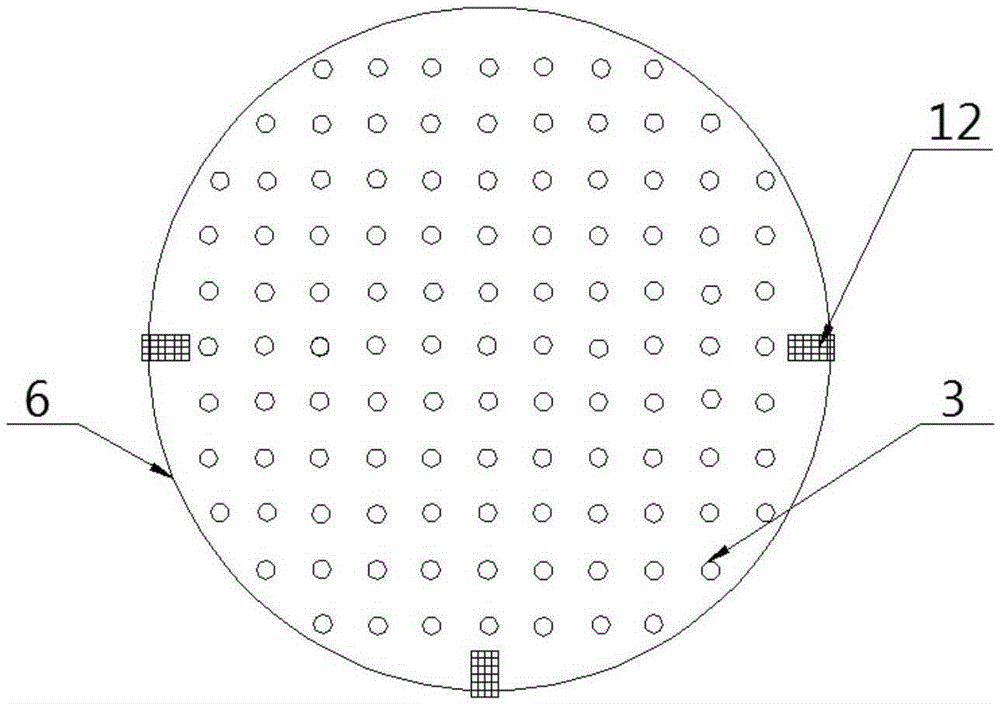

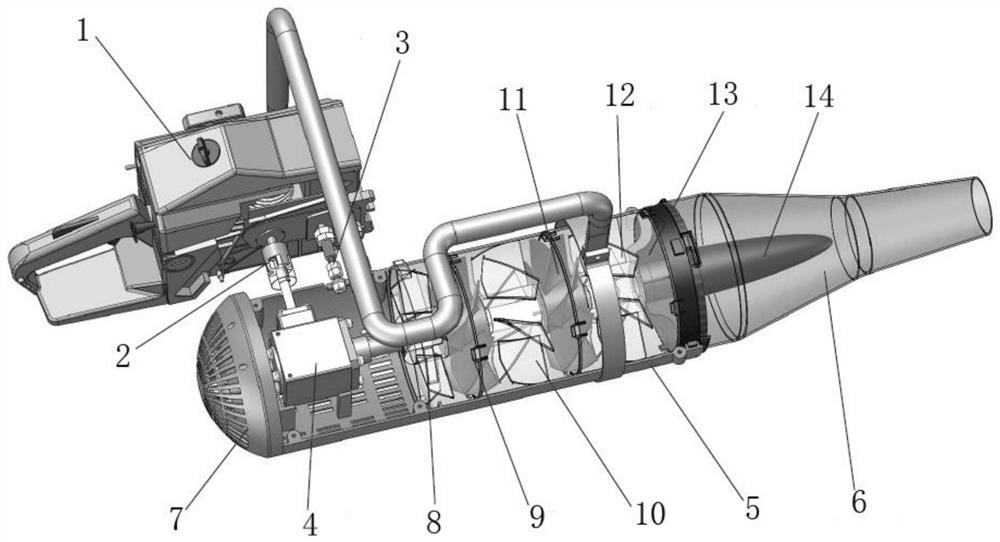

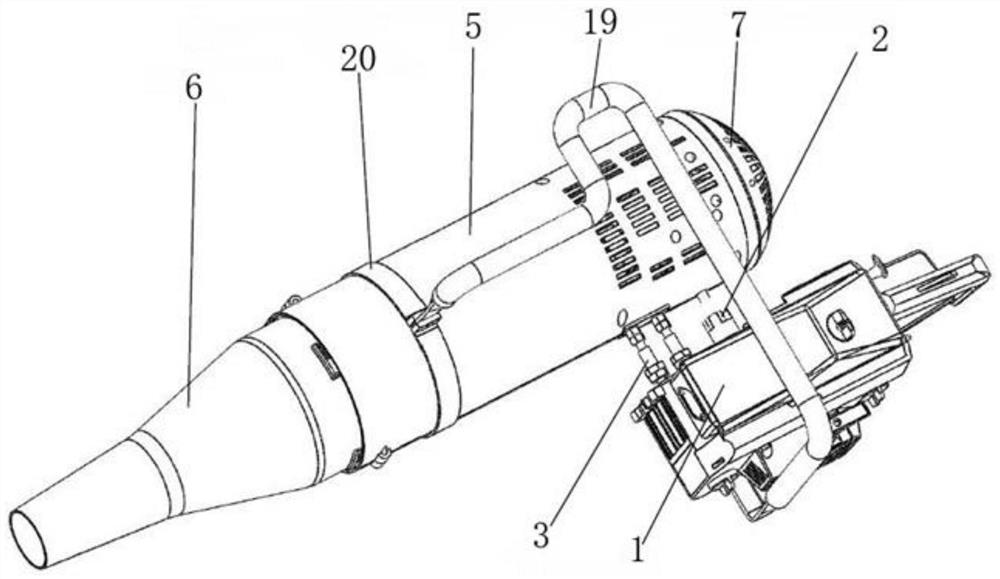

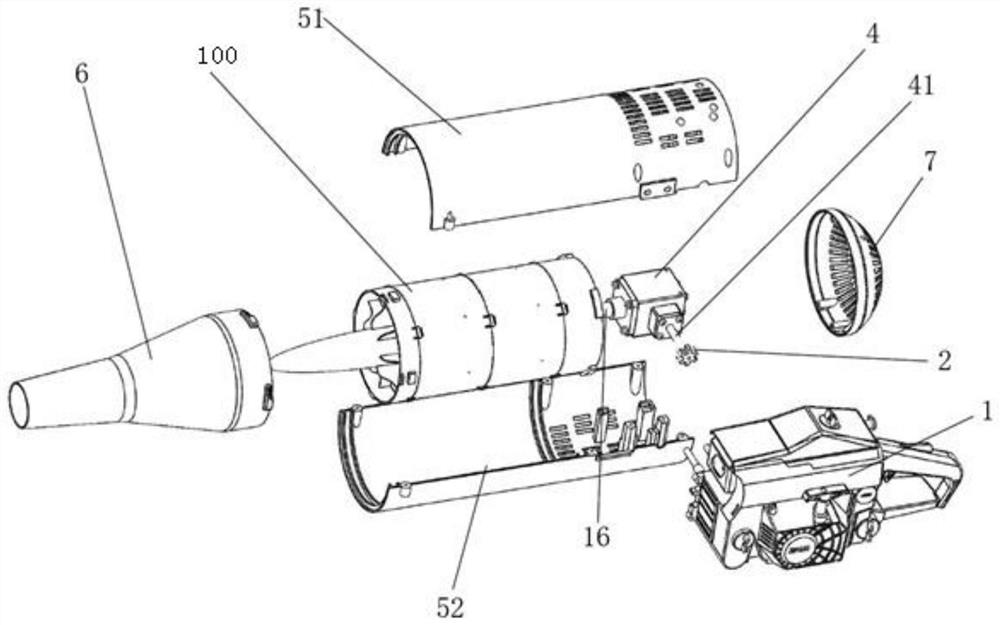

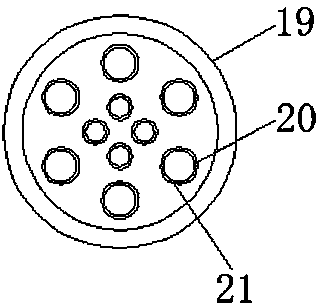

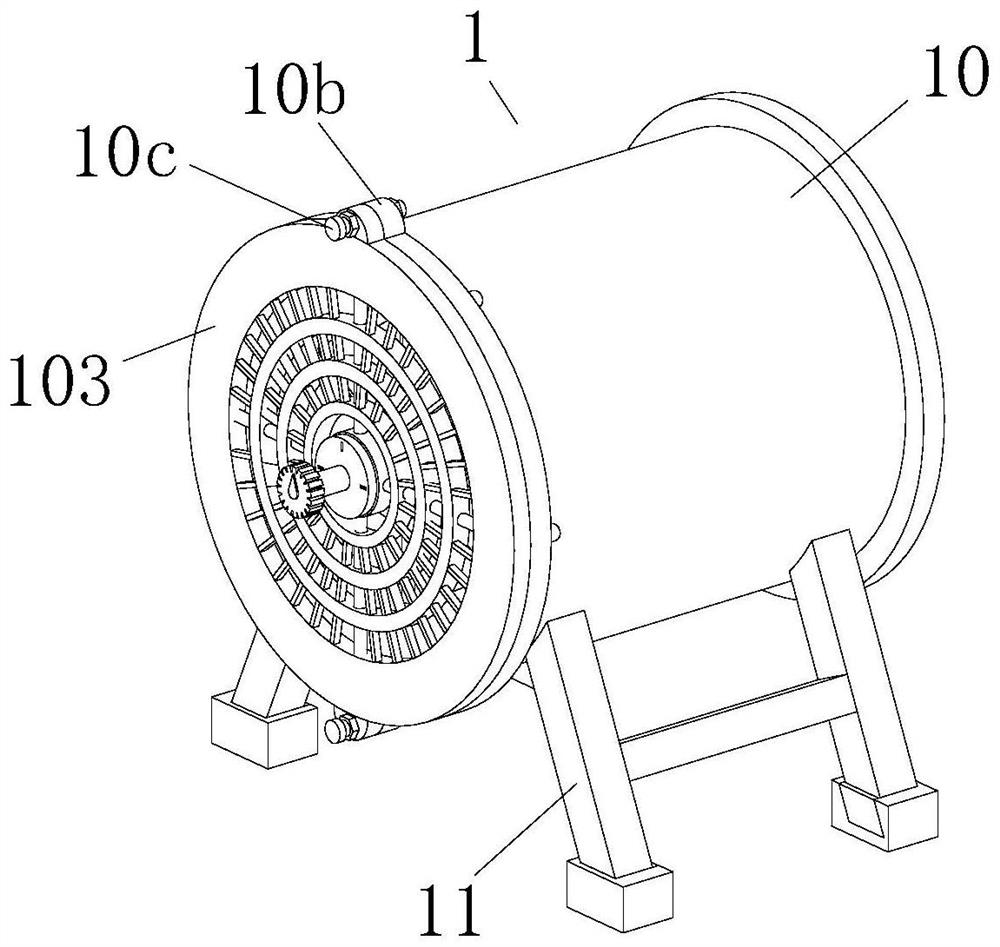

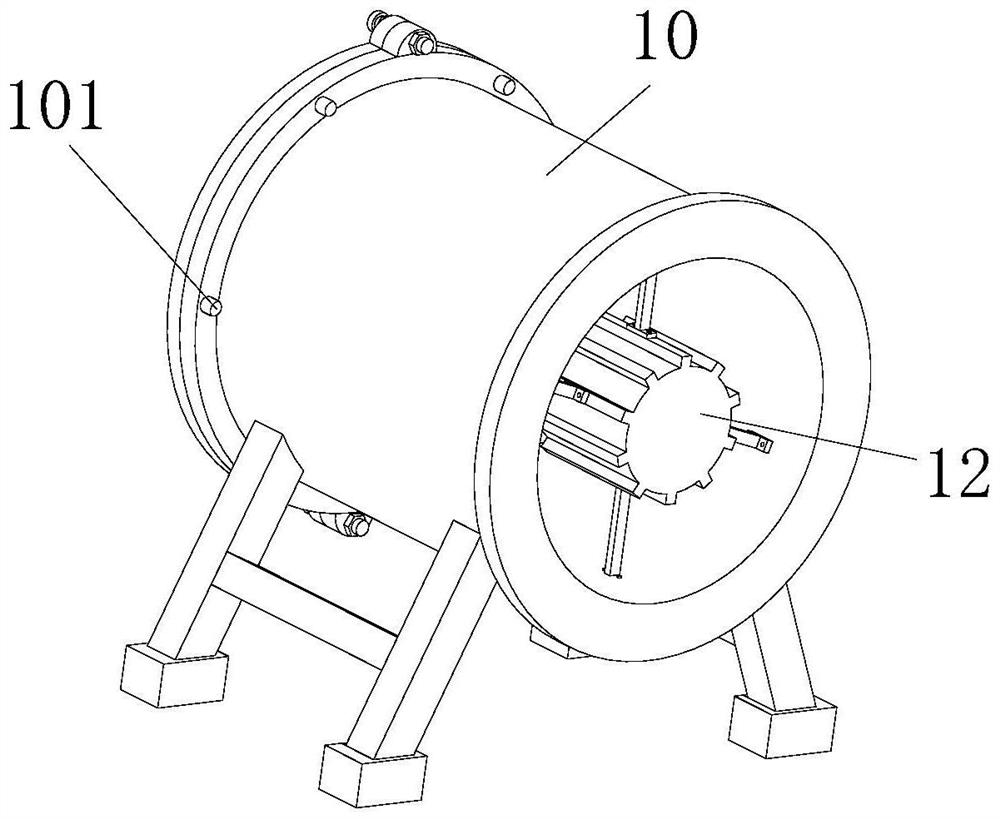

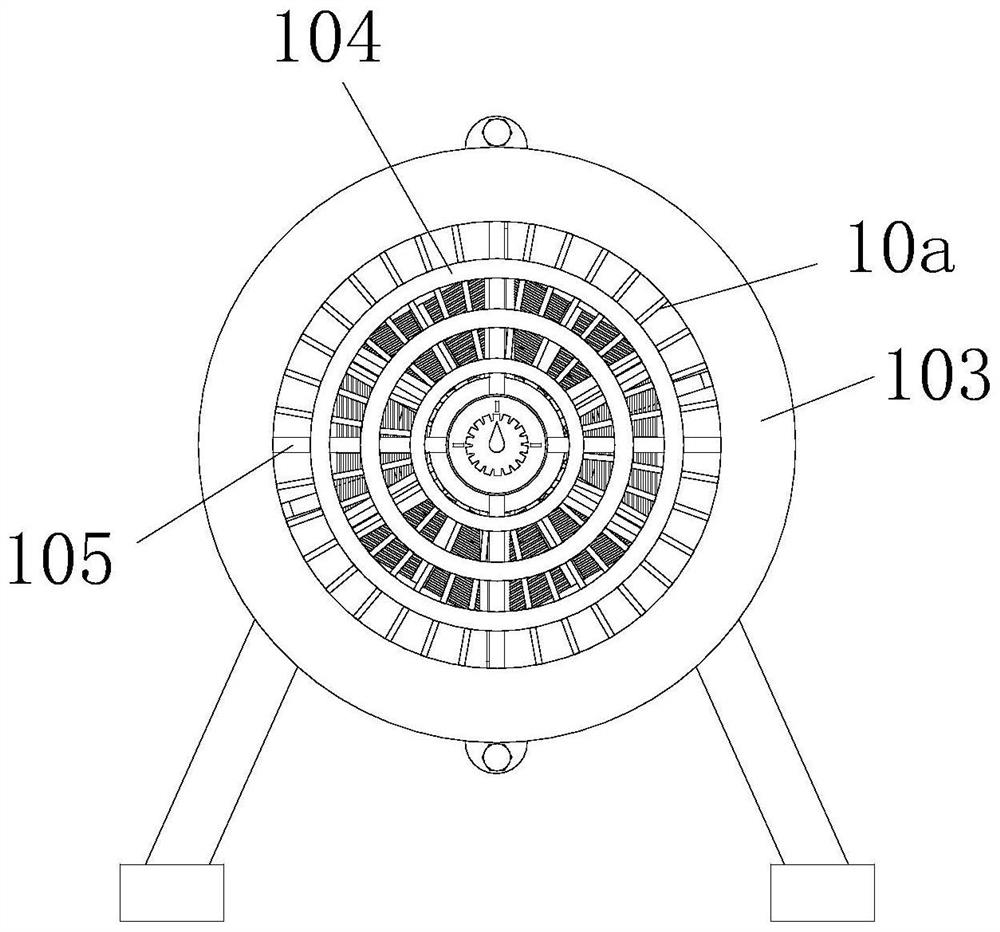

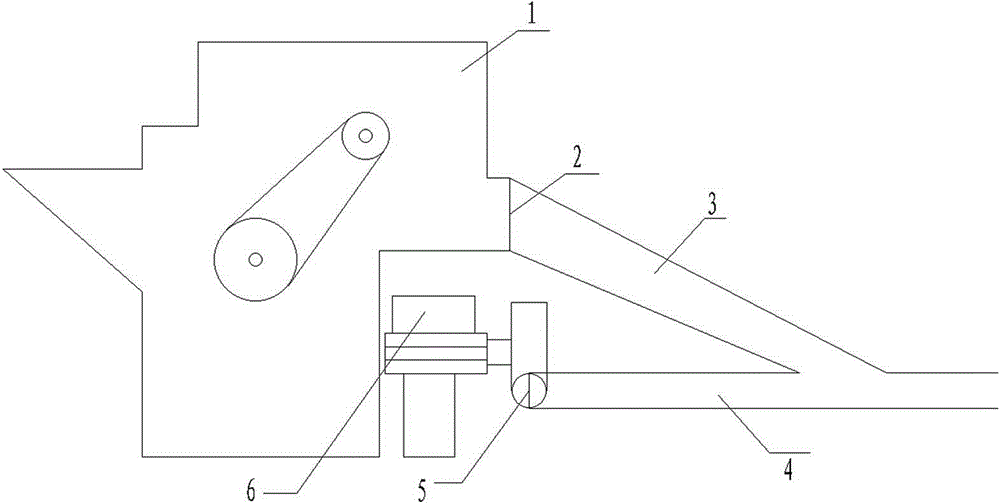

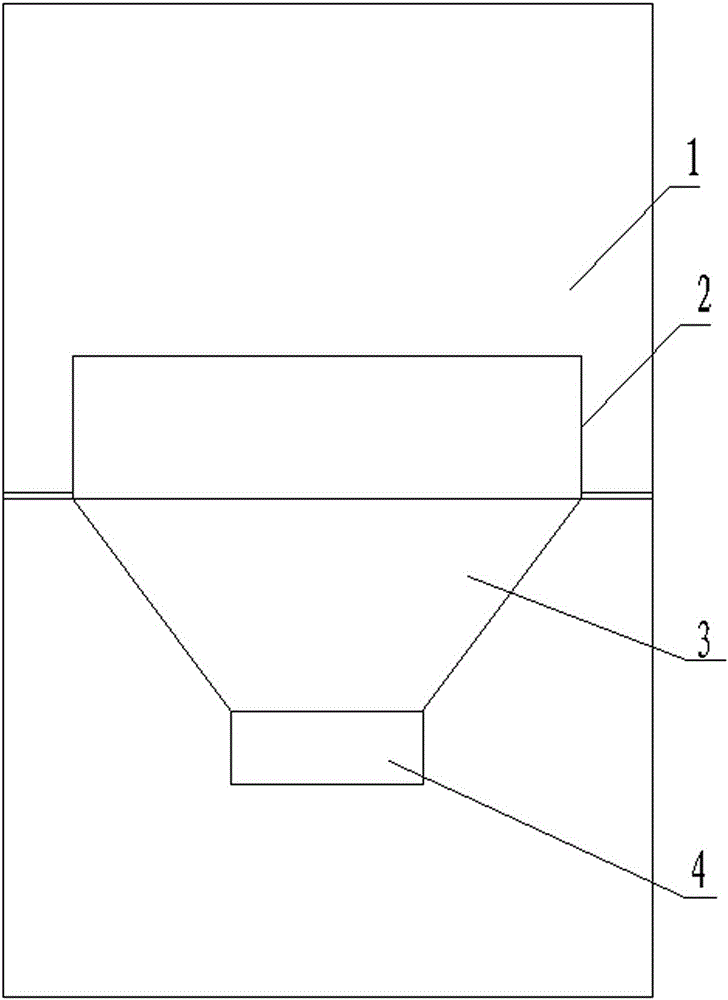

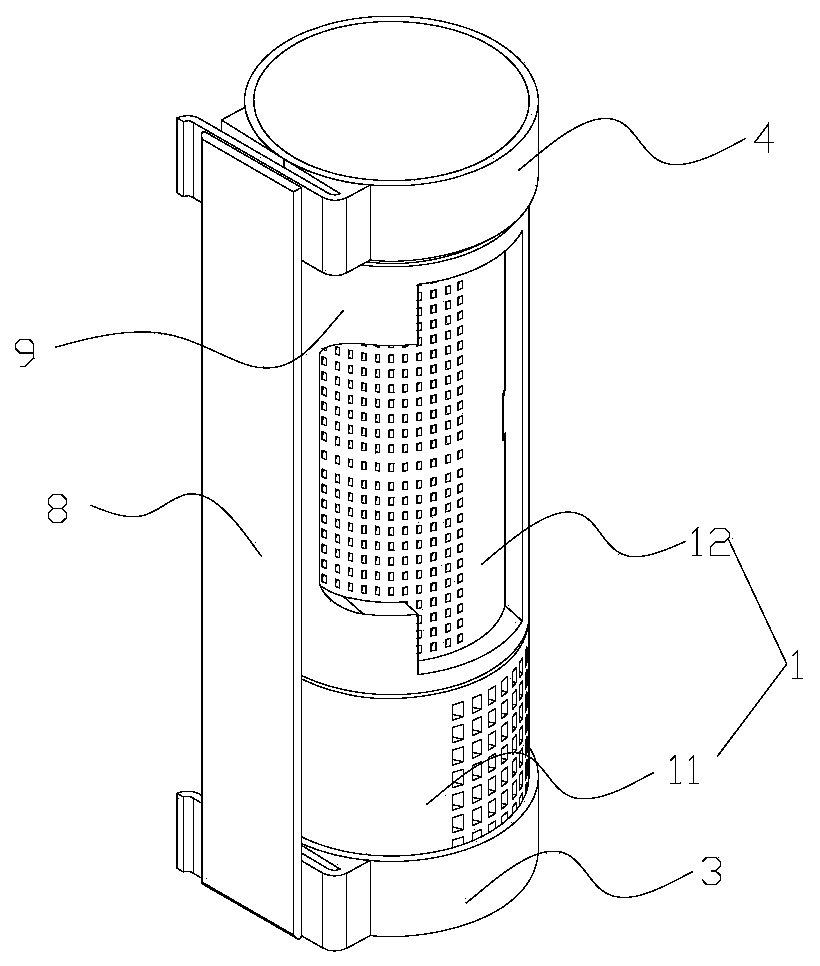

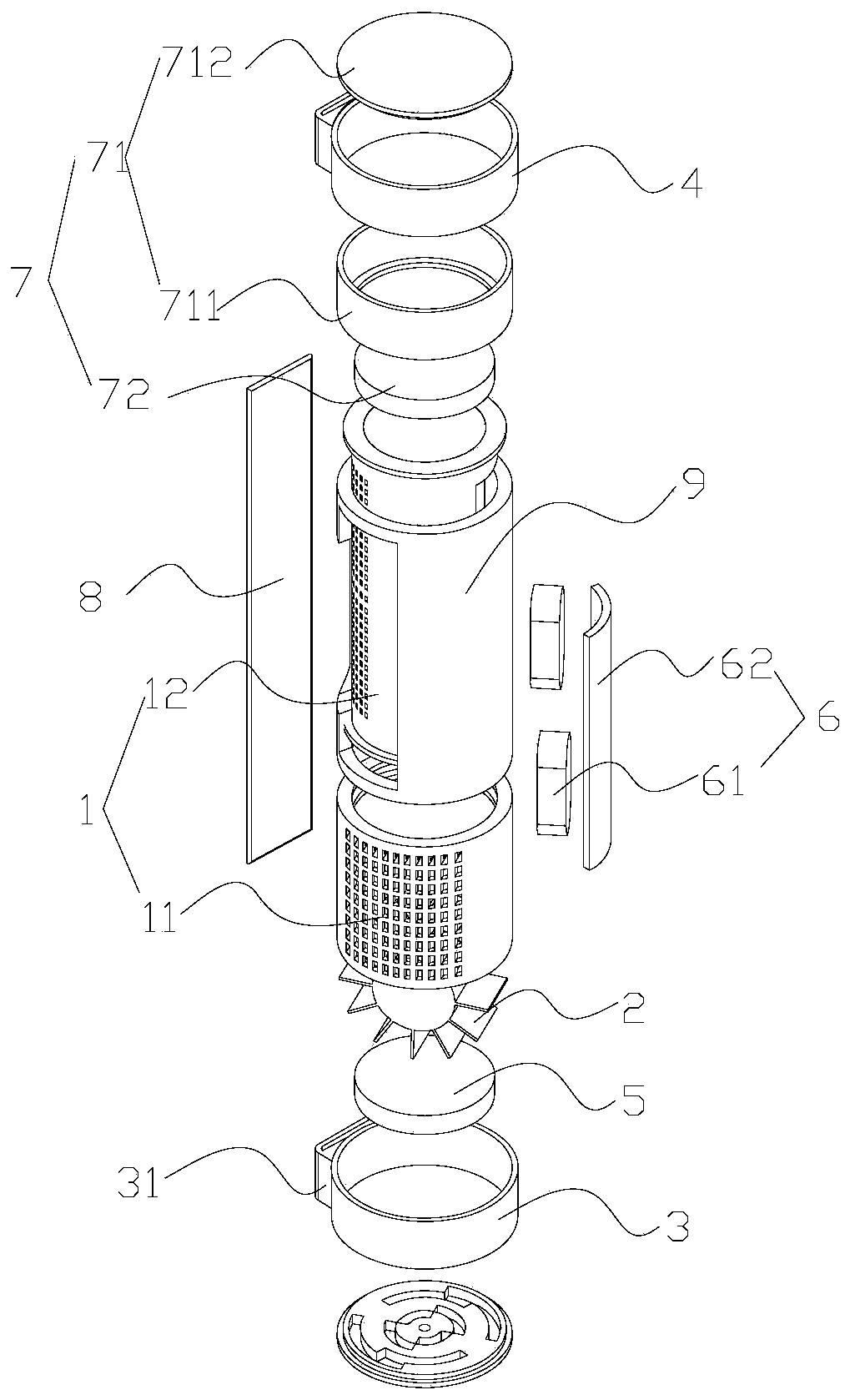

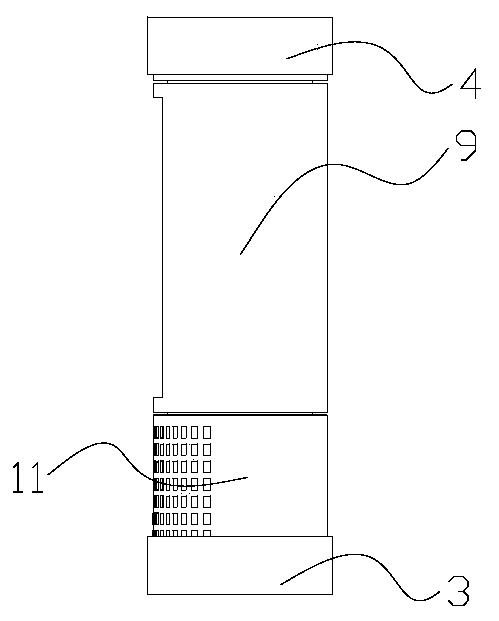

Axial flow type jet fan

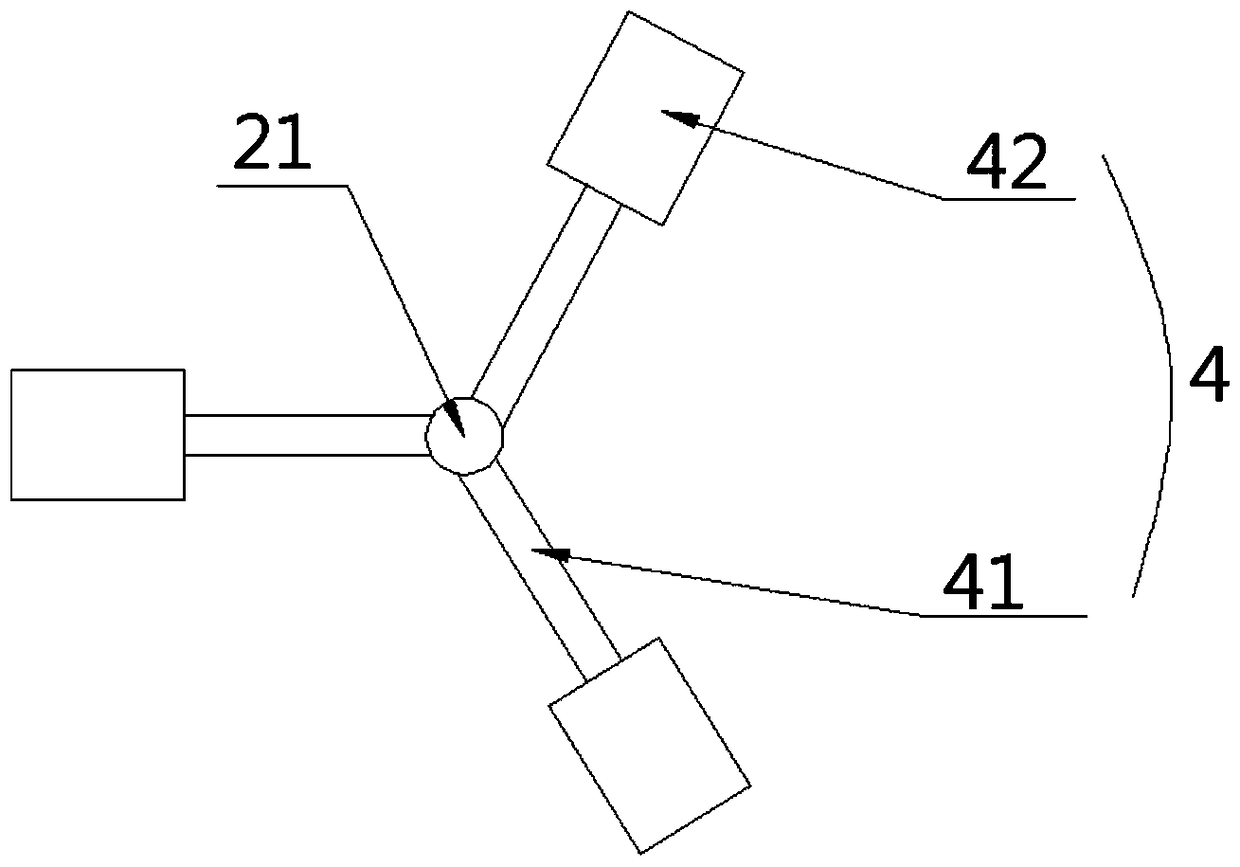

InactiveCN111648986AIncrease pressure and flowImprove work efficiencyPump componentsPump installationsImpellerAir volume

The invention provides an axial flow type jet fan. The axial flow type jet fan comprises a small power source, a shell, a conical air duct, a gear box and a two-stage axial flow fan assembly; the small power source is arranged on the outer part of the shell, the gear box is installed at an air inlet of the shell, an input shaft of the gear box is in transmission connection with the small power source; the conical air duct is installed at the air outlet of the shell, a flow guide cone is arranged in the conical air duct and connected with the two-stage axial flow fan assembly; and the two-stageaxial flow fan assembly is arranged in the inner part of the shell and comprises an inlet rectification grid, a first movable impeller, a first guide vane, a second movable impeller, a second guide vane and an outlet rectification grid, and the inlet rectification grid, the first movable impeller, the first guide vane, the second movable impeller, the second guide vane and the outlet rectification grid are sequentially installed on an output shaft of the gear box. The axial flow type jet fan is simple in structure, light in weight, convenient to use, high in fire extinguishing air speed, large in air volume, high in wind power and good in fire extinguishing effect.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

Film coating device and film coating method thereof

ActiveCN107972914ASimple structureEasy to useWrapping material feeding apparatusWebs handlingAgricultural engineeringFilm-coated tablet

The invention discloses a film coating device which comprises a base, a transmission mechanism arranged above the base, a control mechanism arranged below the base and a film coating mechanism arranged above the transmission mechanism, wherein the film coating mechanism comprises a feeding hole, a discharging hole, a film placement plate, a planishing roller, a film coating roller and an auxiliarycooling roller; the film placement plate is positioned between the feeding hole and the discharging hole and has an upward dip angle of 45-60 degrees; the planishing roller, the film coating roller and the auxiliary cooling roller are sequentially positioned above the film placement plate; two transmission rollers are arranged on two sides of each of the planishing roller, the film coating rollerand the auxiliary cooling roller; the transmission rollers are externally connected with a control motor; and the control mechanism controls and is connected with the transmission mechanism and the control motor. The invention further discloses a film coating method of the film coating device. The film coating device can realize automatic film coating to reduce the labor cost, can adjust the filmcoating direction and time, tightens the coated film, realizes a stagger planishing process to enable the films to be level and smooth enough and unified in structure and meet various production demands and improves the production efficiency and the film coating quality.

Owner:温州市创新晶彩科技有限公司

PVC stabilizing agent sheet cutting system

The invention discloses a PVC stabilizing agent sheet cutting system. The system comprises a dust absorbing device and a reactor. The top of the reactor is provided with a feed inlet. The dust absorbing device comprises a suction hood and an air exhausting device. The suction hood is arranged above the feed inlet. The suction hood and the air exhausting device are connected through a dust absorbing pipe. The air exhausting device comprises an air exhausting cylinder, a position is arranged in the air exhausting cylinder, the piston is connected to a piston rod, one end of the piston rod stretches out the air exhausting cylinder, then the end surface of piston rod is connected to a screw rod motor; the screw rod of the screw rod motor stretches into the sleeve-shaped piston rod, the screw rod and the piston rod are connected through threads, one end of the dust absorbing pipe is connected to the front end surface of the air exhausting cylinder, at least one auxiliary stirring shaft is arranged around the main stirring shaft in the reactor, and the lower ends of the main stirring shaft and auxiliary stirring shaft are both provided with a stirring paddle. The provided system can absorb and suck powdery raw materials, which float around the feed inlet, to avoid floating powdery raw materials, so that the health of workers and safe production can be guaranteed.

Owner:CHONGQING TAIYUE TECH

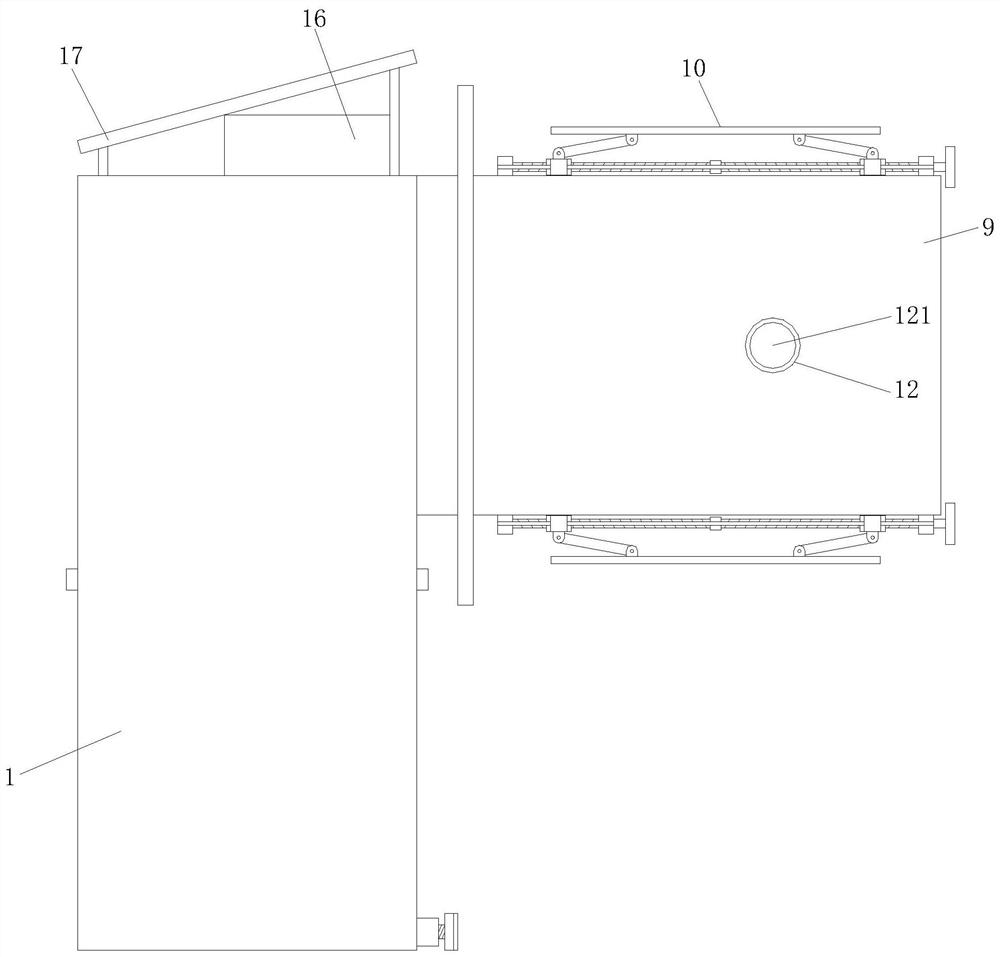

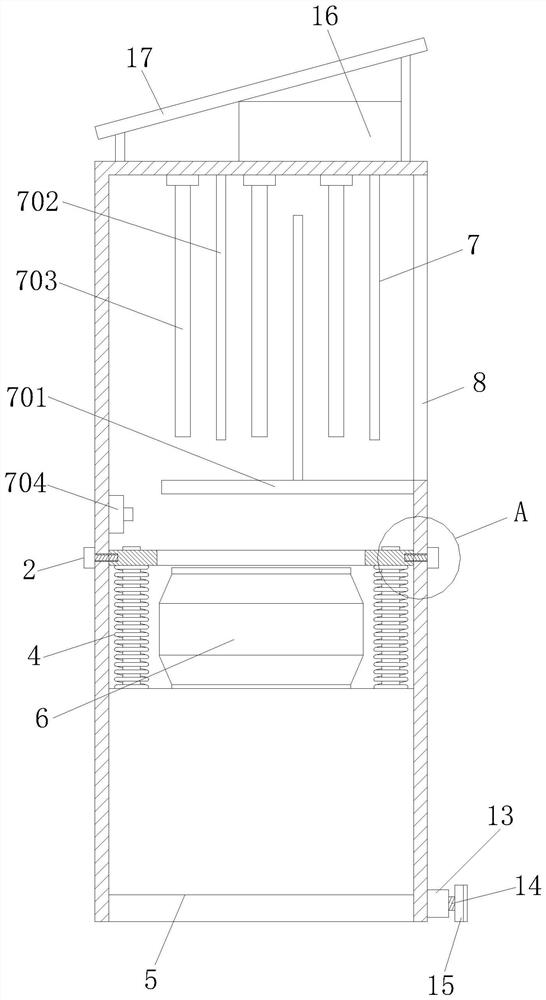

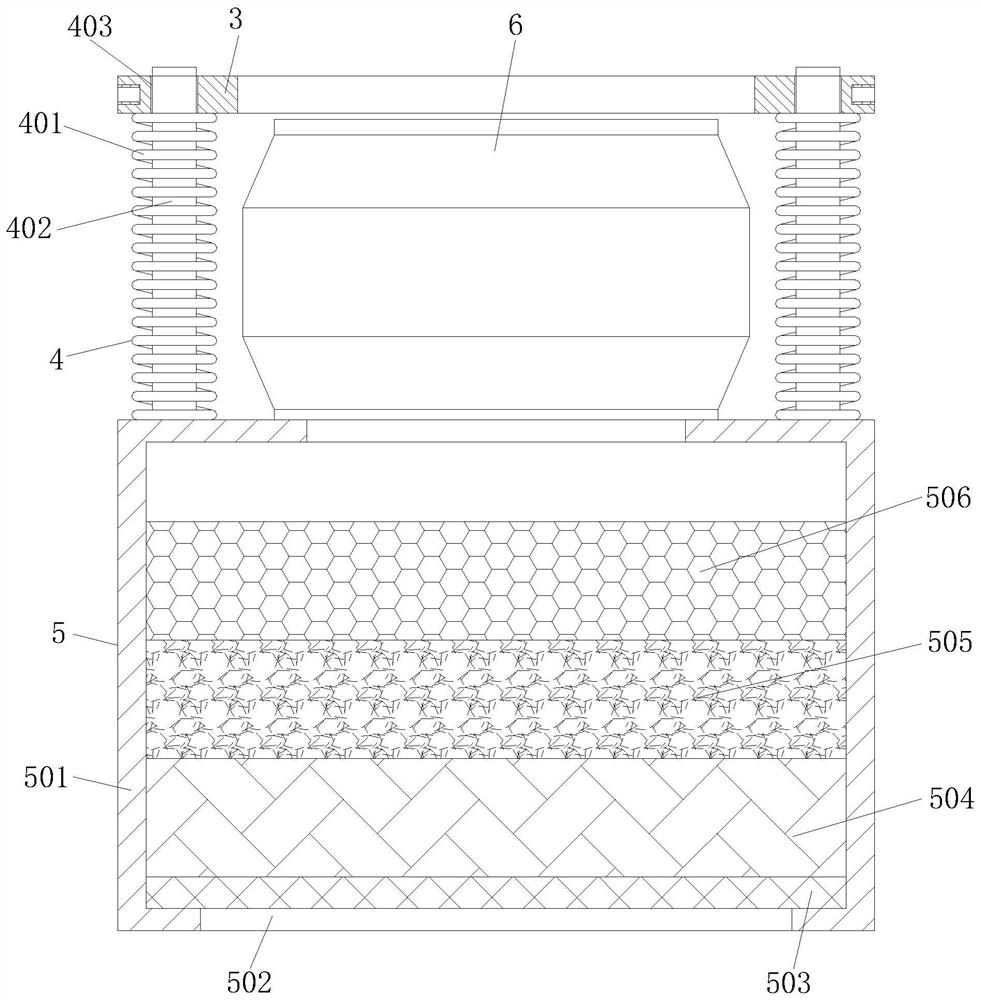

Efficient ventilation structure for steel structure workshop

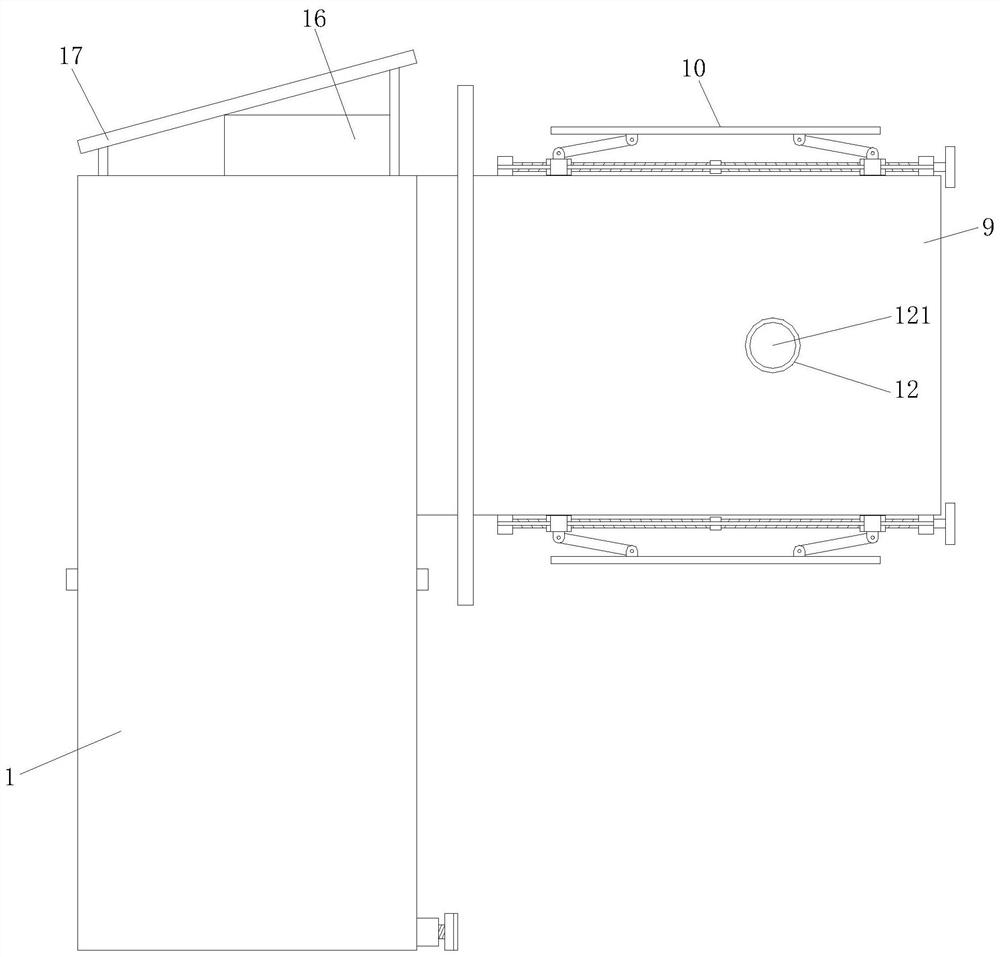

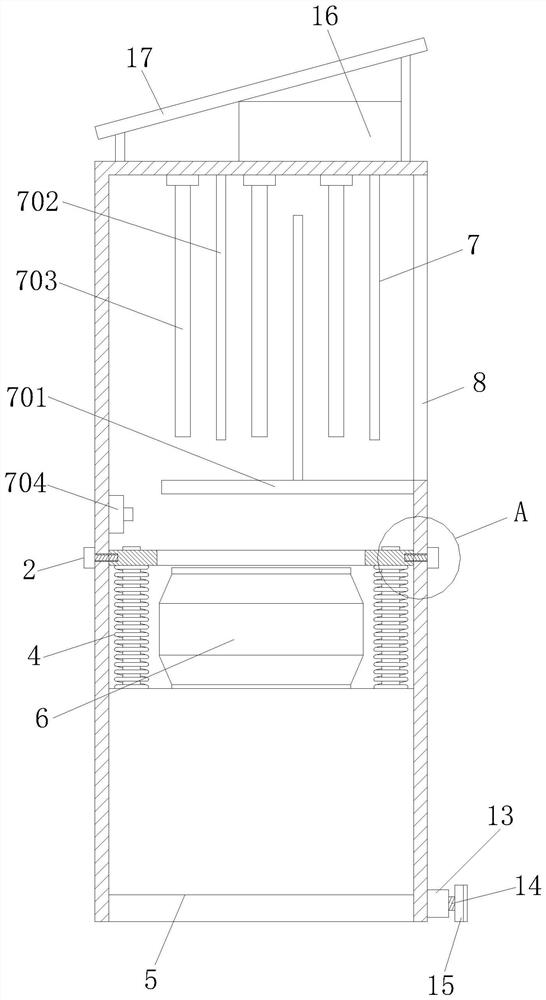

ActiveCN112594837AEfficient ventilation structureWith vibration functionDucting arrangementsMechanical apparatusVentilation tubeClassical mechanics

The invention discloses an efficient ventilation structure for a steel structure workshop, and relates to the technical field of steel structure workshops. The efficient ventilation structure comprises a first ventilation pipe, wherein a rectangular frame is fixedly installed between the inner walls of the first ventilation pipe through a locking mechanism, a filtering mechanism is fixedly installed on the lower surface of the rectangular frame through a buffer piece, a draught fan is fixedly installed on the upper surface of a rectangular box, a dehumidification mechanism is arranged at the position, close to the upper side, in the first ventilation pipe, a second rectangular opening is formed in the right side face of the first ventilation pipe, a second ventilation pipe is fixedly installed on the right side face, corresponding to the second rectangular opening, of the first ventilation pipe, and supporting mechanisms are arranged on the upper side face and the lower side face of the second ventilation pipe correspondingly. According to the ventilation structure, the filtering mechanism has a vibration function and makes dust fall off, the filtering mechanism is not prone to being blocked, the dehumidification mechanism is then used for conveniently dehumidifying entering air and preventing moisture from entering a room, the ventilation structure is conveniently disassembledand assembled through the supporting mechanism, and use is more convenient.

Owner:HUNAN GALAXY STEEL STRUCTURE ENG CO LTD

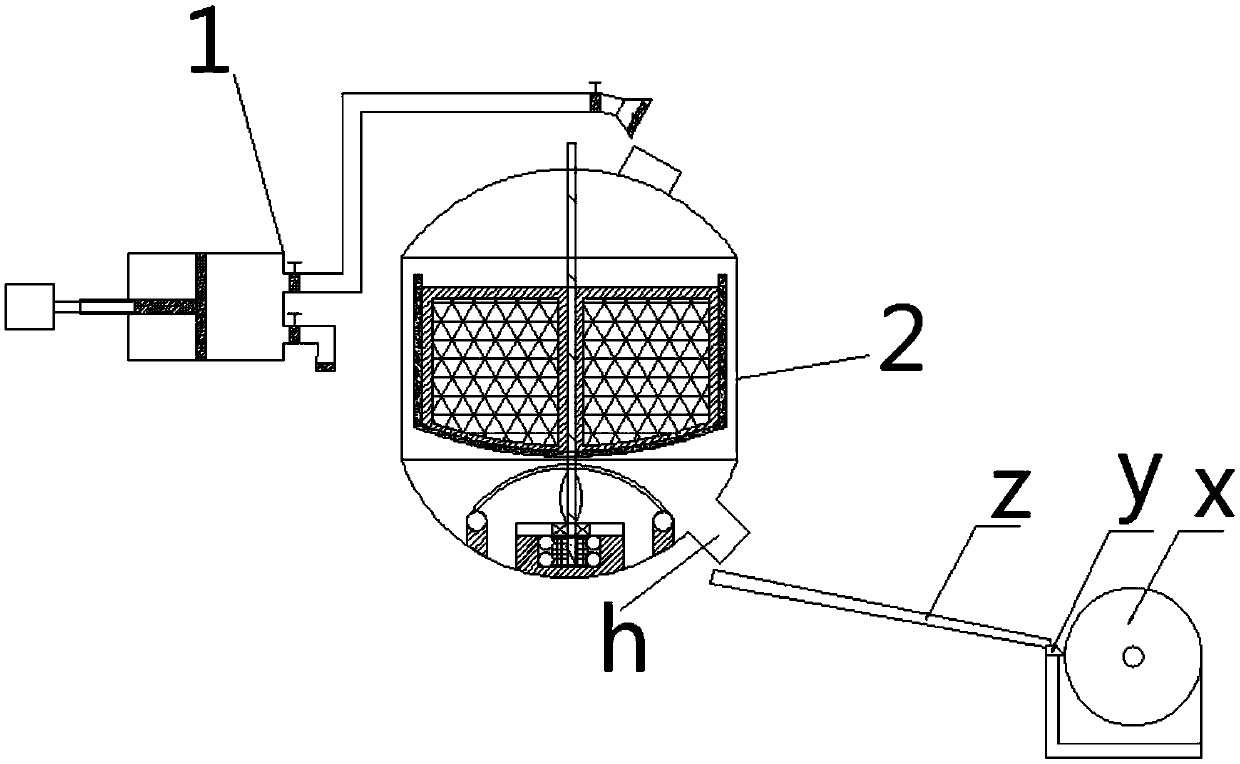

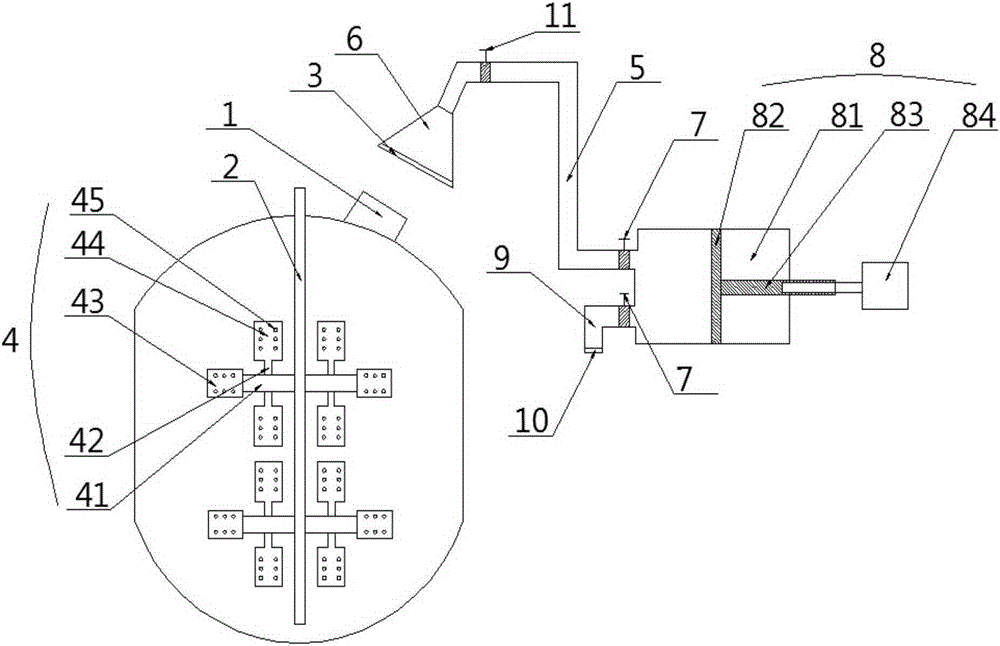

Vacuuming type pvc stabilizer flake processing line

ActiveCN105498666BWell mixedImprove securityDispersed particle filtrationTransportation and packagingHealth safetyPulp and paper industry

The invention discloses a dust-absorbing PVC stabilizer slicing processing line, which comprises a dust-absorbing device, a reaction kettle and a flaking machine. The feeding tray and the flaking machine are located under the reaction kettle, and the reactor is connected to the flaking machine through a diversion chute. The upper end of the diversion chute is located below the discharge port, and the lower end is located above the storage tray; the dust collection device includes a dust collection hood And the air extraction device, the dust suction hood is connected with the air extraction device through the dust suction pipe, the dust suction hood is located above the feeding port, the air extraction device includes an air suction tube with a piston, the piston is connected to the piston rod, and one end of the piston rod extends out of the suction tube The end is connected with the screw motor. There is a stirring spindle in the reactor. The stirring spindle includes the first and second spindles. The first spindle is in the shape of a sleeve. The second spindle is movably sleeved in the first spindle. Stirring paddles are all installed, and the invention can suck the floating powdery raw materials to ensure workers' health and safe production.

Owner:CHONGQING TAIYUE TECH

A high-efficiency ventilation structure for steel structure workshop

ActiveCN112594837BWith vibration functionAvoid easy cloggingDucting arrangementsMechanical apparatusVentilation tubePipe

The invention discloses a high-efficiency ventilation structure for steel structure factory buildings, and relates to the technical field of steel structure factory buildings. It includes a first ventilation pipe, a rectangular frame is fixedly installed between the inner walls of the first ventilation pipe through a locking mechanism, a filter mechanism is fixedly installed on the lower surface of the rectangular frame through a buffer member, and the upper surface of the rectangular box is fixed A fan is installed, and a dehumidification mechanism is provided near the upper side of the first ventilation pipe, and a second rectangular opening is opened on the right side of the first ventilation pipe, and the right side of the first ventilation pipe corresponding to the second rectangular opening is The second ventilation pipe is fixedly installed on the surface, and the upper and lower sides of the second ventilation pipe are provided with supporting mechanisms. The present invention enables the filter mechanism to have a vibration function, so that the dust falls and the filter mechanism is not easy to be blocked, and then the dehumidification mechanism is used to facilitate the dehumidification of the incoming air to prevent moisture from entering the house, and the support mechanism is used to facilitate the disassembly and assembly of the ventilation structure , more convenient to use.

Owner:HUNAN GALAXY STEEL STRUCTURE ENG CO LTD

Metal cleaning device with uniform heating function

InactiveCN108380529ASpread evenlyImprove cleaning efficiencyCleaning using toolsSlide plateEngineering

The invention discloses a metal cleaning device with a uniform heating function. The metal cleaning device comprises a device wall plate, a cleaning plate and a load plate, wherein an air inlet is formed in the interior part of the device wall plate, a warm air blower is arranged on the outer side of the device wall plate, and a fan is arranged in the interior part of the warm air blower; an air sweeping plate is arranged on the inner wall of the device wall plate, an air outlet hole is formed in the surface of the air sweeping plate, sliding plates are fixed on the left side and the right side of the air sweeping plate correspondingly, and a baffle plate is arranged below the air sweeping plate; an air collecting cover is arranged above the device wall plate, a support is arranged in theair collecting cover in a penetrating mode, a connecting rod is arranged below the support, a spray head is arranged below a cleaning disc, and the cleaning disc is located below the connecting rod; and a suction disc is inlaid in the surface of a load disc, and the load disc is located above an air cylinder. The metal cleaning device with the uniform heating function is higher in cleaning efficiency and can be uniformly heated, and good in oil stain cleaning effect and making metal products can be conveniently placed.

Owner:扬州全球鹰机械制造有限公司

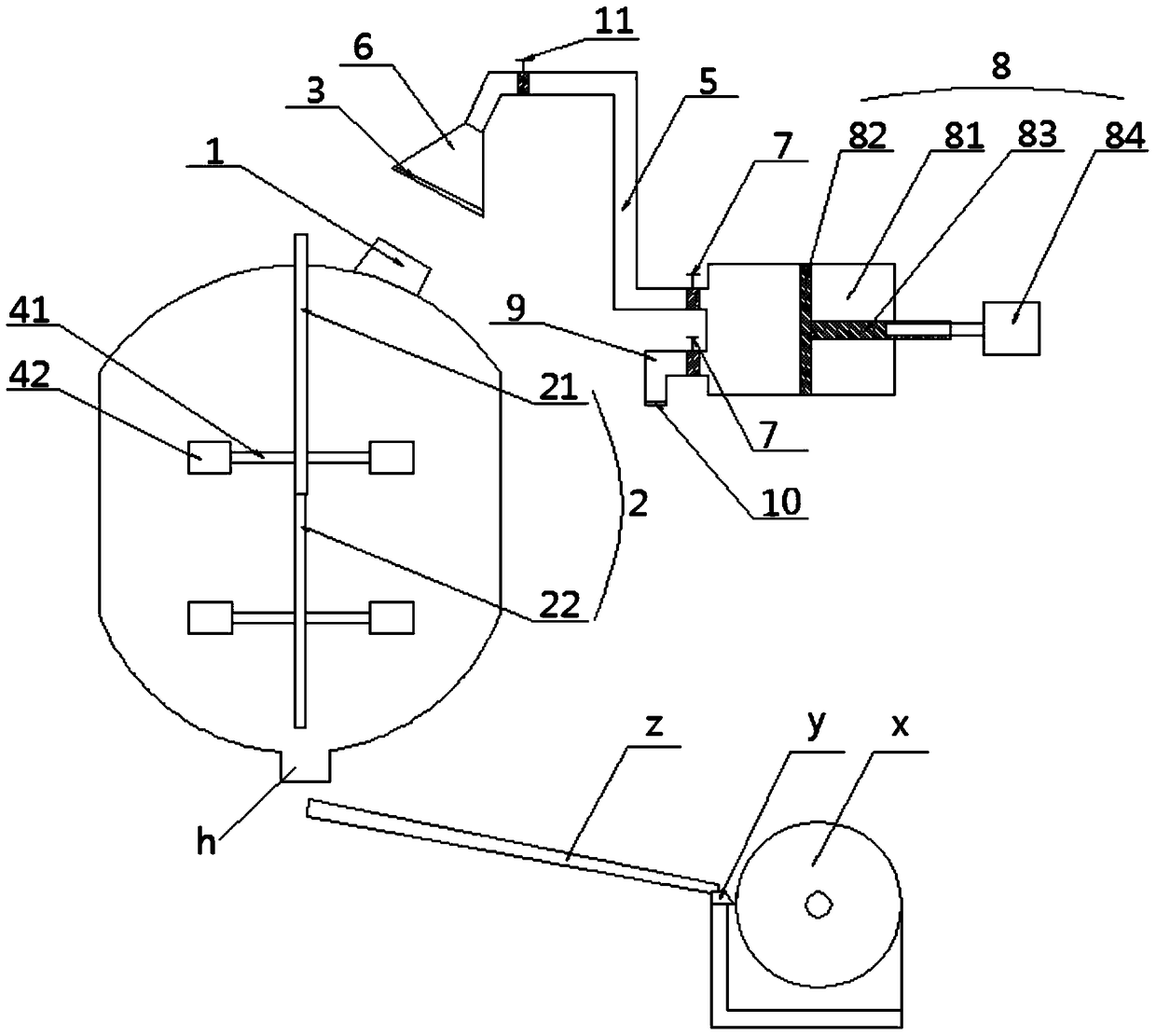

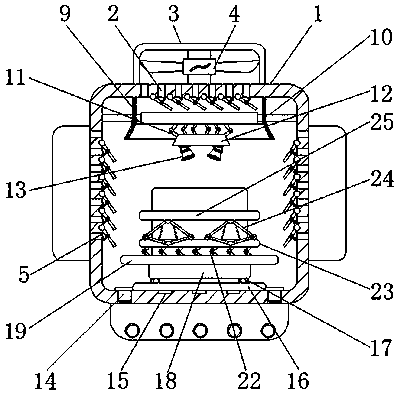

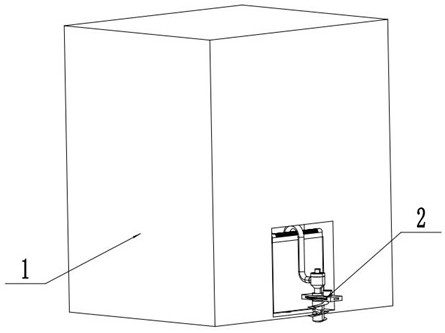

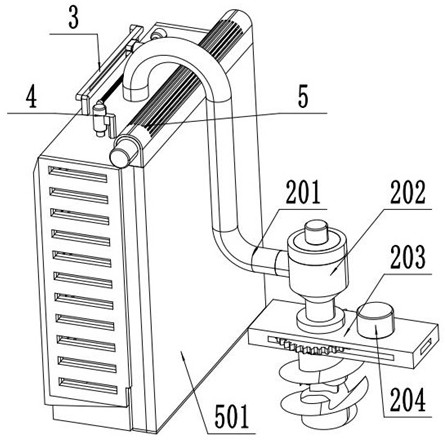

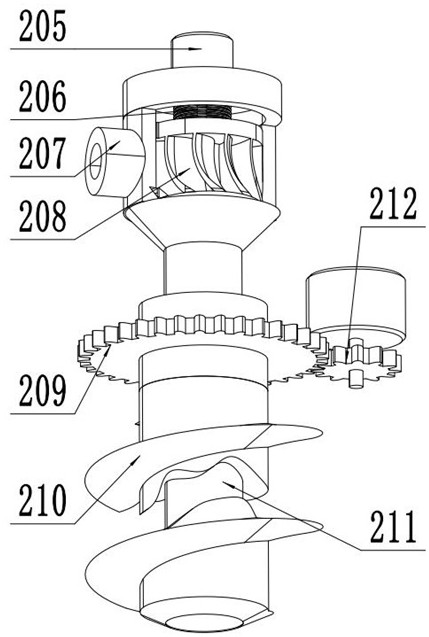

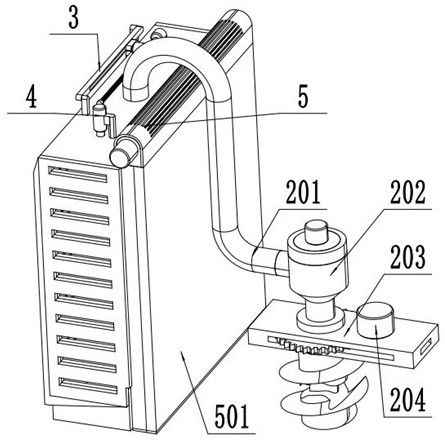

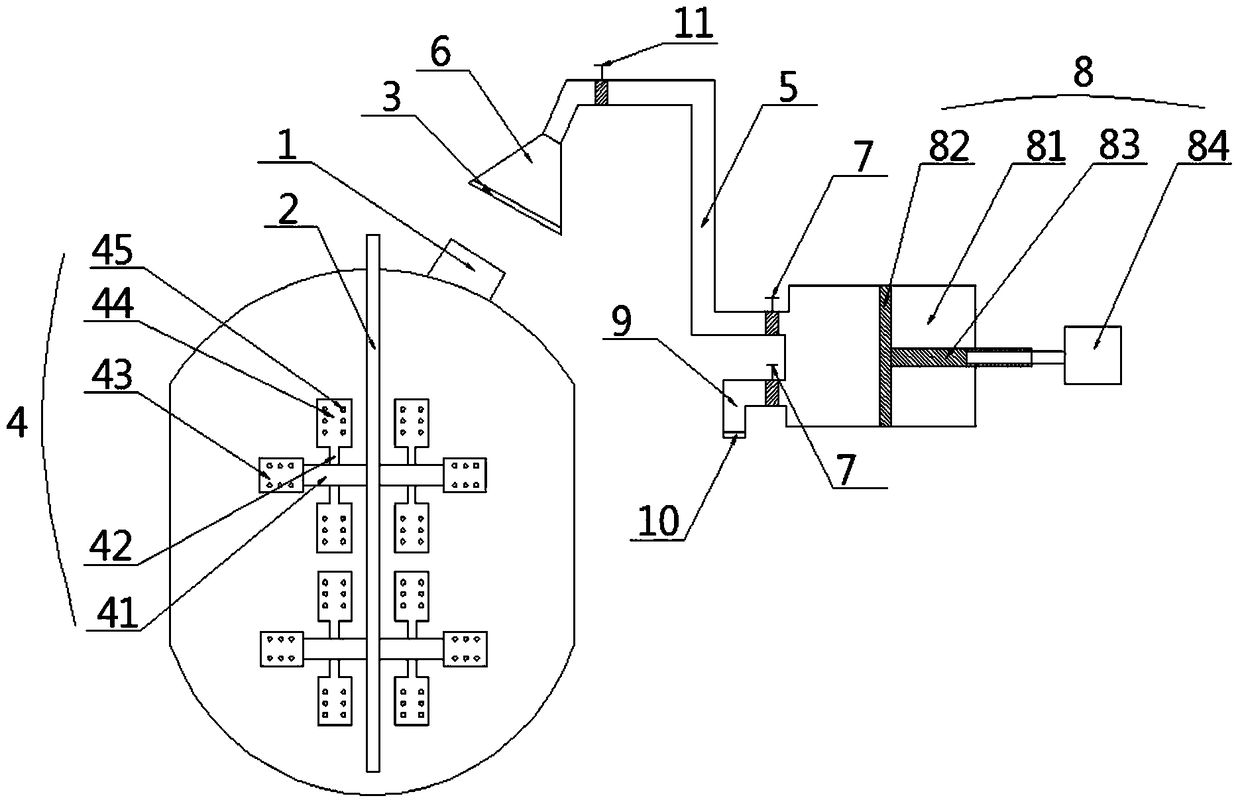

A kind of refrigeration equipment suitable for electrical cabinets under high temperature conditions

ActiveCN113518548BChange sizeControl contact areaConstructionsPump installationsWind runCooling effect

The invention discloses a refrigeration device suitable for electrical cabinets under high-temperature conditions, which relates to the technical field of refrigeration, and includes a water supply mechanism, a diffuser mechanism, a cooling mechanism, and an air supply mechanism installed in the electrical cabinet, and the diffuser mechanism makes the airflow flow, The cooling mechanism includes a number of water guide plates arranged in the refrigeration box, two adjacent water guide plates are arranged alternately and every two water guide plates are rotatably connected by cooling connecting rods, and one end of the lowermost water guide plate is set There are counterweights to guide the flow of water, and the air supply mechanism realizes multi-angle air supply. The invention uses underground cold water, controls the contact area between air flow and cold water flow, and adjusts the wind direction and speed to cool down the electrical cabinet. It is energy-saving and environmentally friendly, and has a good cooling effect. , high cooling efficiency.

Owner:徐州金宸制冷设备有限公司

Electric appliance cabinet refrigeration equipment suitable for high-temperature condition

ActiveCN113518548AChange sizeControl contact areaConstructionsPump installationsAir velocityWater flow

The invention discloses electric appliance cabinet refrigeration equipment suitable for a high temperature condition, and relates to the technical field of refrigeration. The electric appliance cabinet refrigeration equipment comprises a water supply mechanism, an air dispersion mechanism and a cooling mechanism which are installed in an electric appliance cabinet, the air supply mechanism and the air dispersion mechanism enable air flow to flow, and the cooling mechanism comprises a plurality of water guide plates arranged in a refrigeration box; two adjacent water guide plates are arranged in a staggered mode, every two water guide plates are rotationally connected through a cooling connecting rod, a balancing weight is arranged at one end of the lowermost water guide plate, water flow is guided to flow, and the air supply mechanism achieves multi-angle air supply. According to the invention, underground cold water is used in a cycled way, the contact area between the air flow and the cold water flow is controlled, and the wind direction and speed are adjusted to cool the electric appliance cabinet; and thus, the energy is saved, the environment is protected, the refrigeration effect is good, and the refrigeration efficiency is high.

Owner:徐州金宸制冷设备有限公司

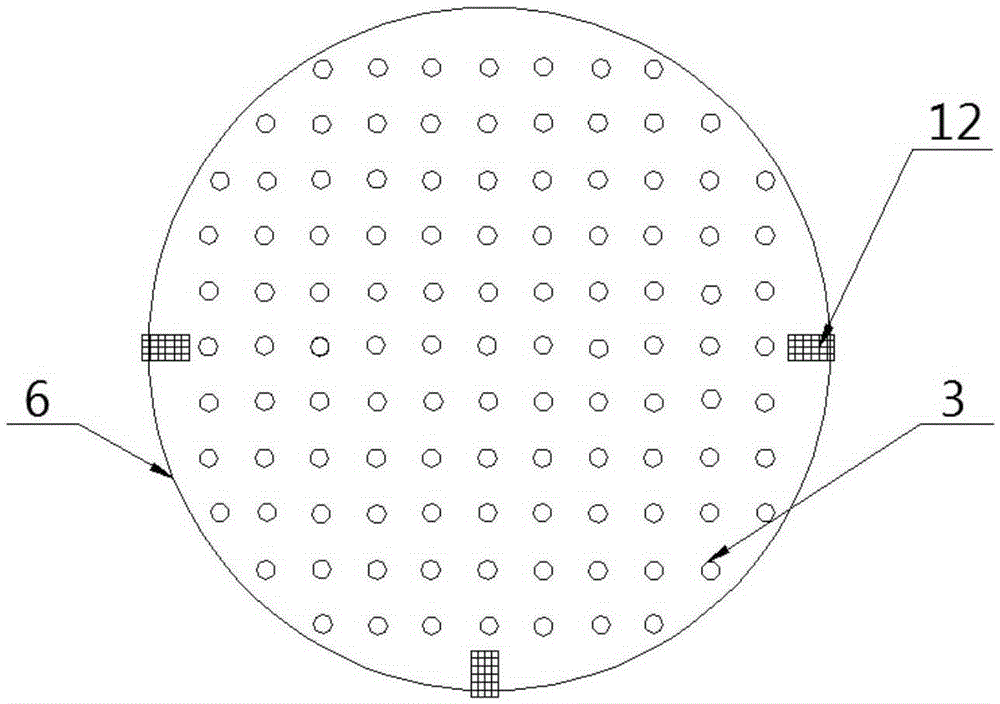

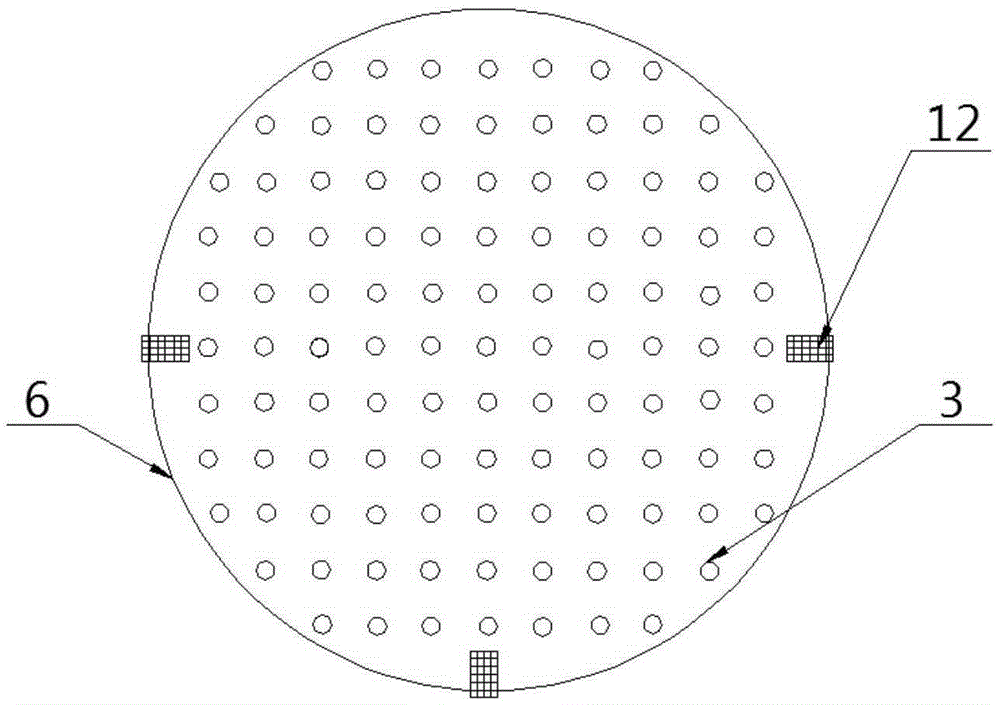

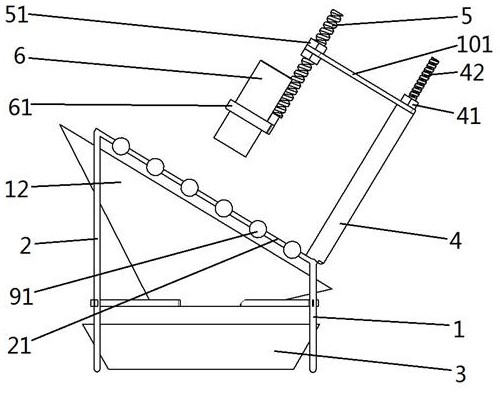

Silkworm cocoon removing device

InactiveCN113243342AIngenious designAdjust the size of the windAnimal husbandryEngineeringAir blower

The invention relates to a silkworm cocoon removing device. The silkworm cocoon removing device is characterized in that a first supporting leg set, a second supporting leg set, a second adjusting screw rod, an air blower and a supporting plate serve as a main body; the second supporting leg set is higher than the first supporting leg set; a fixing frame fixedly connected with the second adjusting screw rod is arranged at the bottom of the second adjusting screw rod, and the air blower fixedly connected with the fixing frame is arranged in the fixing frame. Silkworm cocoons in silkworm cocoon lattices are blown off to the lower end of a steel wire mesh through the air blower, meanwhile, adhesion between the silkworm cocoons and the silkworm cocoon lattices is pulled apart through the steel wire mesh in the process of moving the silkworm cocoon lattices, and the design is ingenious; the position relation between the second adjusting screw rod and a kidney-shaped connecting frame and the position relation between the first adjusting screw rod and the kidney-shaped connecting frame are locked through a fixing nut set and a locking nut respectively, so that the position of the air blower and the size of the air blowing force of the air blower to a cocoon inlet can be adjusted, and therefore the device can adapt to the silkworm cocoon lattices of different thicknesses; and the device is moved by holding the silkworm cocoon lattices, silkworm cocoons in the silkworm cocoon lattices are completely removed, use is easy, and operation is convenient.

Owner:宿迁米喆机械设计有限公司

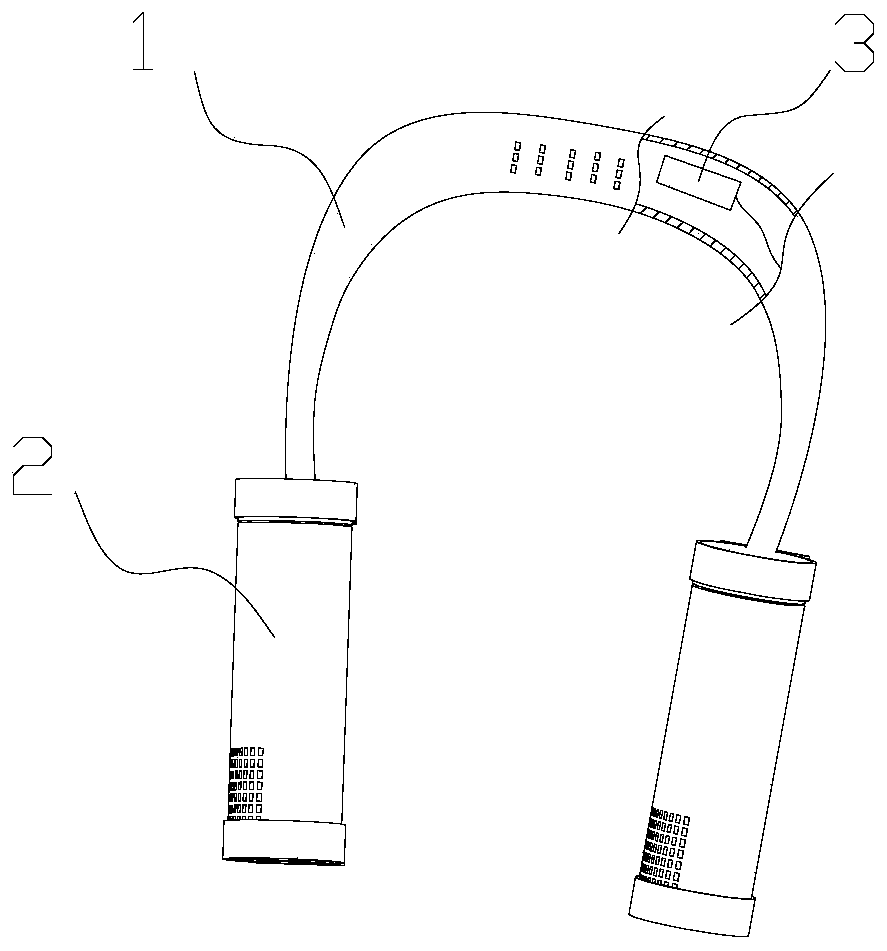

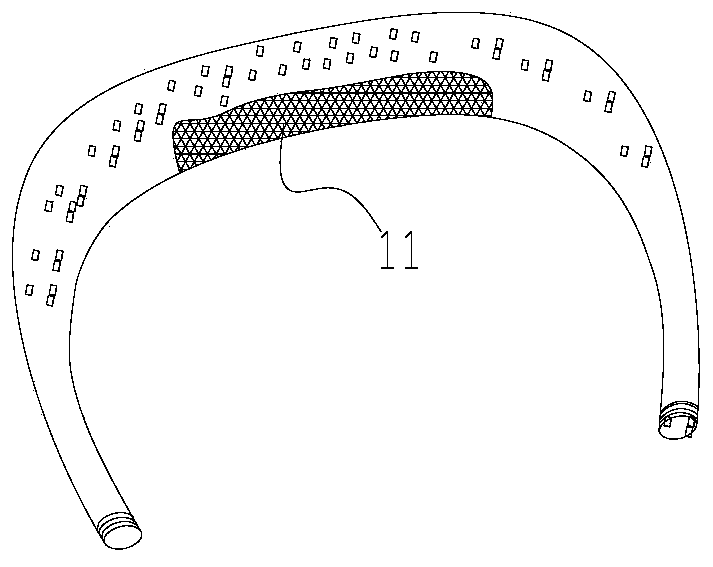

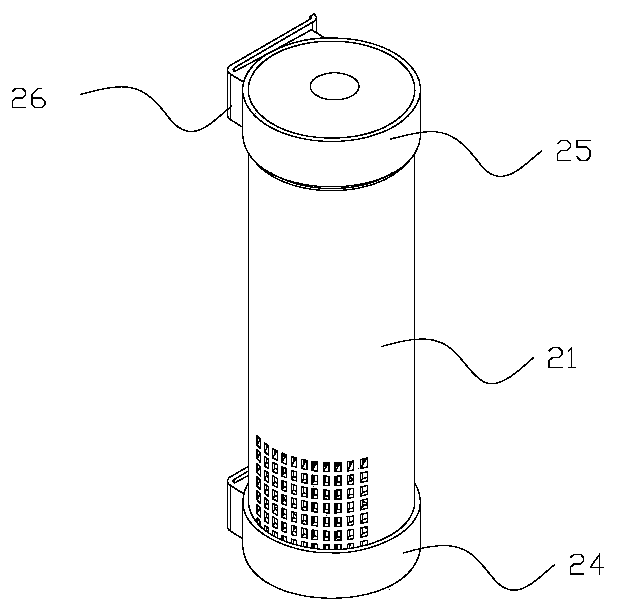

Hanging type air conditioner

The invention discloses a hanging type air conditioner. The hanging type air conditioner comprises a hanging ring for hanging, an air conditioner body and a power supply device, wherein a cavity is formed in the hanging ring; the air conditioner body is detachably mounted at the end of the hanging ring; the power supply device is mounted in the hanging ring or / and the air conditioner body; the airconditioner body comprises a housing, a draught fan assembly and a filtering piece; the draught fan assembly is fixed in the housing; the housing is provided with an air inlet; the housing or / and thehanging ring is provided with an air outlet; and the draught fan assembly is mounted in the housing and connected with the power supply device. The hanging type air conditioner has the beneficial effects that the hanging ring is used for the neck, and the two hands can be liberated; and the air conditioner body introduces air through the air inlet, the air is purified through the filtering pieceand then is led out through the air outlet in the housing or / and the hanging ring, the face, the neck and the head can be cooled, and the functions of purifying and temperature adjusting are achieved.

Owner:泗县恒星烫画机械股份有限公司

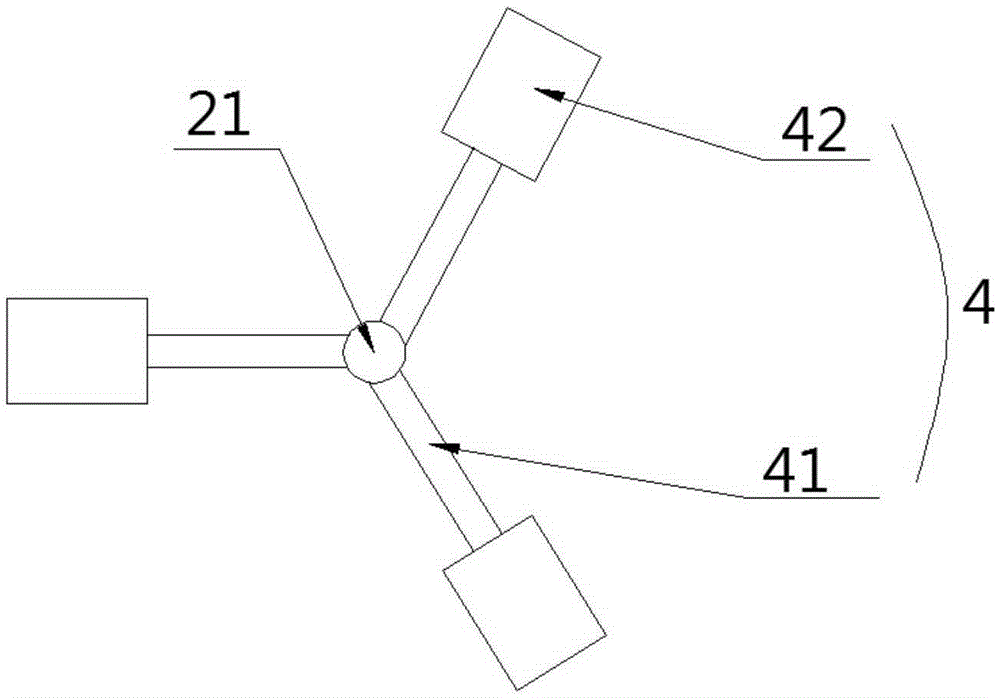

Wind detection and displacement adjustment unit and its intelligent adjustment of doors and windows

ActiveCN112282610BAdjust the size of the windAdjustable sizeVentilation arrangementPower-operated mechanismStructural engineeringControl theory

The invention provides a wind force detection displacement adjustment unit and an intelligent adjustment door and window thereof. The adjustment unit includes a second ventilation area opened on a vertical door and window, and a second chute is arranged directly above the second ventilation area; Under the combined action of the first electromagnet and the second electromagnet on the left and right sides of the slot, the sliding shaft fixedly connected with the wind measuring plate in the second chute can slide left and right; the wind measuring plate can drive the sliding shaft to approach and move away from it. The direction of the door and window is rotated, and the sliding shaft drives the moving baffle plate used to adjust the size of the actual ventilation area to move; the second ventilation area is also provided with a leveling structure, and the leveling structure includes a first cross bar parallel to the second chute , each first crossbar is distributed in the order from left to right and the height gradually decreases, and the upper first crossbar in each adjacent two first crossbars is fixedly connected with the lower first crossbar through the first connecting rod; each A pressure sensor is provided on the upper surface of each of the first cross bars for detecting whether the wind measuring plate is in contact with the corresponding first cross bar.

Owner:佛山市南海金帝凯斯门窗科技有限公司

Dust suction type PVC (polyvinyl chloride) stabilizing agent sheet cutting processing flow line

ActiveCN105498666AWell mixedImprove securityDispersed particle filtrationTransportation and packagingPolyvinyl chlorideHealth safety

The invention discloses a dust suction type PVC (polyvinyl chloride) stabilizing agent sheet cutting processing flow line, which comprises a dust suction device, a reaction kettle and a sheet forming machine, wherein a feeding opening is formed in the top of the reaction kettle; a discharging opening is formed in the bottom of the reaction kettle; a material storage disc is arranged on the sheet forming machine; the sheet forming machine is positioned under the reaction kettle; the reaction kettle is connected with the sheet forming machine through a flow guide inclined groove; the upper end of the flow guide inclined groove is positioned under the discharging opening; the lower end of the flow guide inclined groove is positioned above the material storage disc; the dust suction device comprises a dust suction cover and a gas suction device; the dust suction cover is connected with the gas suction device through a dust suction pipe; the dust suction cover is positioned above the feeding opening; the exhaust device comprises an exhaust tube provided with a piston; the piston is connected with a piston rod; one end of the piston rod extends out of the back end of the gas extraction tube and is connected with a screw motor; a stirring main shaft is arranged in the reaction kettle, and comprises a first main shaft and a second main shaft; the first main shaft is in a sleeve barrel shape; the second main shaft is movably arranged in the first main shaft in a sleeving way; a stirring paddle is respectively arranged on the first main shaft and the second main shaft. The flow line provided by the invention has the advantages that floating powdery raw materials can be sucked, and the health of workers and the safe production can be ensured.

Owner:CHONGQING TAIYUE TECH

pvc stabilizer stirring section line

ActiveCN105498377BWell mixedImprove securityDispersed particle filtrationTransportation and packagingBiochemical engineeringPiston rod

The invention discloses a PVC stabilizer stirring and slicing assembly line, which comprises a dust suction device, a reaction kettle and a flaking machine. The flake machine is located under the reaction kettle, and the reactor and the flake machine are connected through a diversion chute. The upper end of the diversion chute is located below the discharge port, and the lower end is located above the storage tray; the dust collection device includes a dust collection hood and an air extraction device. , the two are connected by a suction pipe, the dust cover is located above the feeding port, the air extraction device includes an air pump with a piston, the piston is connected to a piston rod, and one end of the piston rod extends out of the rear end of the air pump and is connected to the screw motor , one end of the dust suction pipe is connected to the front end of the air pump, a stirring spindle is arranged in the reactor, the upper part of the stirring spindle extends out of the reactor, and at least one set of stirring paddles is installed on the stirring spindle. Suction the powdery raw materials to avoid the flying of powdery raw materials and ensure the health and safety of workers.

Owner:CHONGQING TAIYUE TECH

Improved axial flow fan

PendingCN113915149ARealize the angle adjustment functionRealize the adjustment functionPump componentsPump controlGear wheelElectric machinery

Owner:毛辉

A dust suction reaction system with a combined stirring paddle

ActiveCN105344305BWell mixedImprove securityDispersed particle filtrationRotary stirring mixersPhysical healthScrew thread

The invention discloses a dust suction reaction system with a combined stirring paddle, which includes a dust suction device and a reactor. The top of the reactor is provided with a feeding port, and the dust suction device includes a dust suction cover and an air suction device located above the feeding port. , the two are connected by a dust suction pipe, the air extraction device includes an air extraction cylinder with a piston inside, the piston is connected with a piston rod, one end of the piston rod extends out of the rear end of the air extraction cylinder and is connected with the screw motor, and the screw rod of the screw motor It extends into the sleeve-shaped piston rod and is threaded with it. There is a stirring shaft in the reactor. Type stirring blade, the present invention can suck the powdery raw materials floating at the feeding port during the feeding process, avoid the flying of powdery raw materials, and ensure the health of workers and the safe production of the factory.

Owner:CHONGQING TAIYUE TECH

Wind power detection displacement adjusting unit and intelligent adjusting door and window thereof

ActiveCN112282610AAdjust the size of the windAdjustable sizeVentilation arrangementPower-operated mechanismStructural engineeringControl theory

The invention provides a wind power detection displacement adjusting unit and an intelligent adjusting door and window thereof. The adjusting unit comprises a second ventilation area, wherein the second ventilation area is formed on a vertical door and window, and a second chute is formed right above the second ventilation area; a sliding shaft which is fixedly connected with a wind measuring plate in the second chute can slide from left to right under the combined action of a first electromagnet and a second electromagnet on the left and right sides of the second chute, the sliding shaft canbe driven to rotate in the direction which is close to or away from the door and window by the wind measuring plate, and a movable baffle which is used for adjusting the size of an actual ventilationarea is driven to move by the sliding shaft; a stage adjusting structure is further arranged in the second ventilation area, the stage adjusting structure comprises first transverse rods which are parallel to the second chute, all of the first transverse rods are distributed from left to right, the heights of the first transverse rods are gradually reduced, and the first transverse rod on the upper side in every two adjacent first transverse rods is fixedly connected with the first transverse rod on the lower side through a first connecting rod; and a pressure sensor is arranged on the upper surface of each first transverse rod and is used for detecting whether the wind measuring plate is abutted with the corresponding first transverse rod or not.

Owner:佛山市南海金帝凯斯门窗科技有限公司

Drying equipment and application thereof

ActiveCN112893049ARelieve shrinkage stressAvoid or reduce cracksPretreated surfacesLiquid spraying apparatusCoated surfacePtru catalyst

The invention discloses drying equipment and application thereof, belongs to the technical field of overall configuration catalyst preparation equipment, and solves the problem that the coating firmness is poor due to the fact that a coating cracks or strips in the drying process of a coated slurry coating of an existing honeycomb metal matrix. According to the drying equipment, hot air is provided by an arranged hot air supply assembly, atomized water is provided by a water supply assembly, and the hot air and the atomized water are mixed through an air-water mixer to form an air-water mixture, and then the air-water mixture dries a to-be-dried product placed on a supporting platform. According to the drying equipment, the slurry coating loaded on the honeycomb metal matrix is dried with the hot air with certain humidity, so that shrinkage stress caused by the difference between the drying rate of the surface of the coating and the drying rate of the interior of the coating in the drying process of the slurry coating can be effectively relieved, and then the probability that the surface of the coating cracks is avoided or reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A multi-blade stirring dust suction reaction system

InactiveCN105344306BReduce ups and downsWell mixedDispersed particle filtrationDirt cleaningEngineeringMechanical engineering

The invention discloses a multi-blade stirring-type dust collecting reaction system which comprises a dust collecting device and a reaction kettle, wherein a feeding opening is formed in the top of the reaction kettle; the dust collecting device comprises a dust collecting cover and an air suction device; the dust collecting cover is positioned above the feeding opening; the dust collecting cover and the air suction device are connected through a dust collecting pipe; the air suction device comprises an air suction cylinder in which a piston is arranged; the piston is connected with a piston rod; one end of the piston rod stretches out from the back end surface of the air suction cylinder and is connected with a screw rod motor; a screw rod of the screw rod motor stretches into the sleeve-shaped piston rod, and is in threaded connection with the piston rod; one end of the dust collecting pipe is connected with the front end surface of the air suction cylinder; a stirring main shaft is arranged in the reaction kettle; the upper part of the stirring main shaft stretches out of the reaction kettle; at least one set of stirring paddles is mounted on the stirring main shaft. Powdery raw materials floating at the feeding opening in the feeding process can be sucked, powdery raw material flying can be avoided, and health of workers and safe production of a factory can be ensured.

Owner:CHONGQING TAIYUE TECH

Conveying device of fluff feeder

The invention discloses a conveying device of a fluff feeder. The conveying device comprises a pipeline, and is characterized by further comprising a slideway connected with a cotton fabric outlet of the fluff feeder; the slideway is connected with an output channel of a blower through a hook arranged at the lower end of the slideway; a variable-speed resistor is arranged on the blower. The conveying device is relatively high in conveying capacity and low in cost, and has the advantages that the conveying speed can be adjusted freely, and not too much working space is occupied while the production efficiency is improved.

Owner:安徽中福毛纺制帽有限公司

Air shield device

PendingCN111380140AAchieve angle adjustmentAdjustable temperatureBreathing filtersAir heatersEngineeringAir conditioning

The invention discloses an air shield device. A shell, a draught fan assembly, a first rotation barrel, a second rotation barrel, a filter piece and a power supply device are included. The first rotation barrel can be rotationally in cup joint to one end of the shell, and the second rotation barrel can be rotationally in cup joint to the other end of the shell. The draught fan assembly is fixed inthe shell. The shell comprises an air inlet shell and an air outlet shell. One end of the air inlet shell can be rotationally connected with one end of the air outlet shell. The air inlet shell is provided with an air inlet, and the air outlet shell is provided with an air outlet. The draught fan assembly is connected with the power supply device. The air shield device has the beneficial effectsthat air is purified, the temperature is adjusted, saliva, droplets and other impurities are hindered, and the air shield device is more suitable for being used outdoors.

Owner:泗县恒星烫画机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com