Dust suction type PVC (polyvinyl chloride) stabilizing agent sheet cutting processing flow line

A stabilizer and sheet processing technology, which is used in the removal of smoke and dust, chemical/physical/physical-chemical stationary reactors, and dispersed particle filtration. effect and other issues, to achieve the effect of less mixing blind spots, reducing safety and health hazards, and ensuring physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

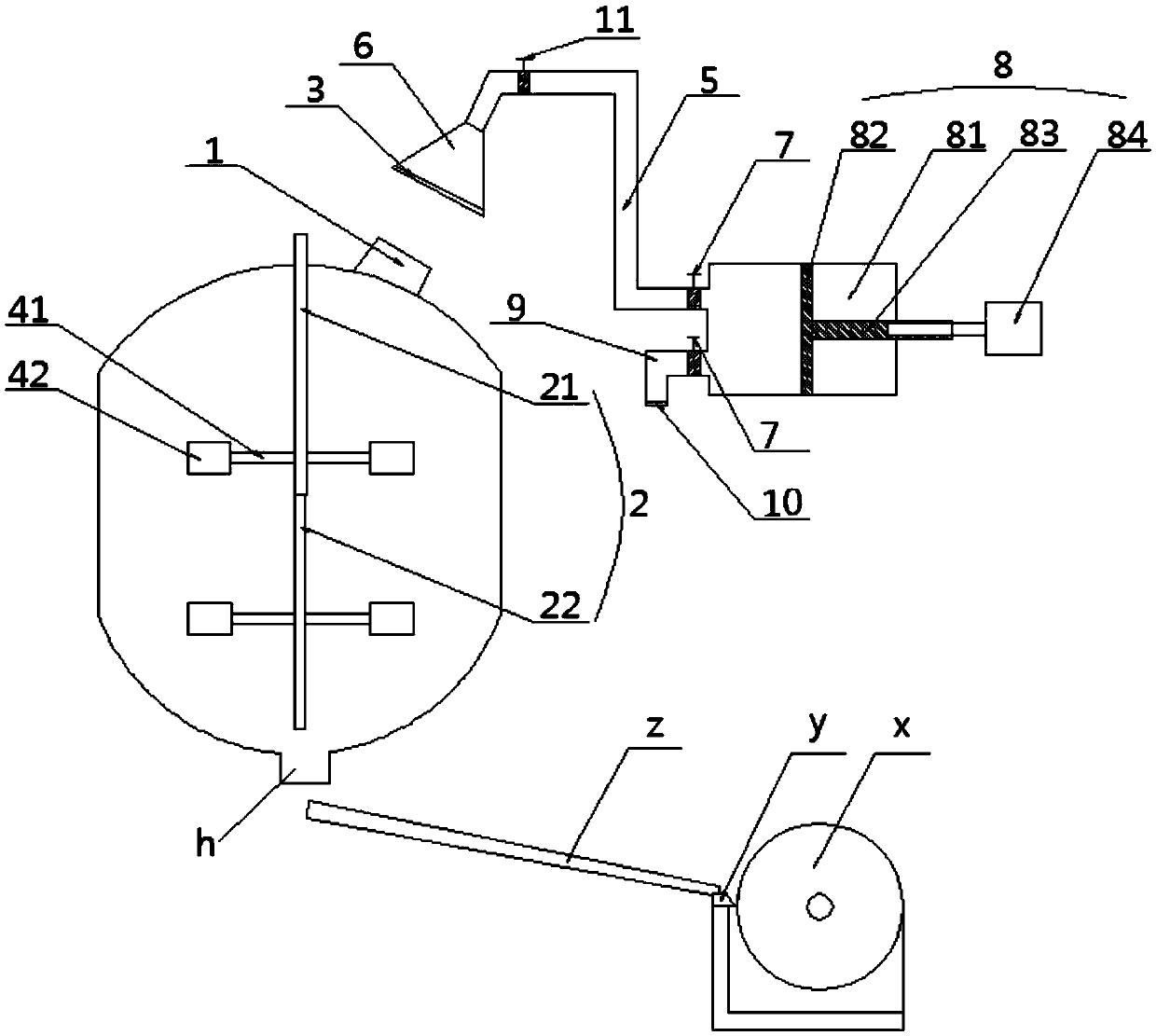

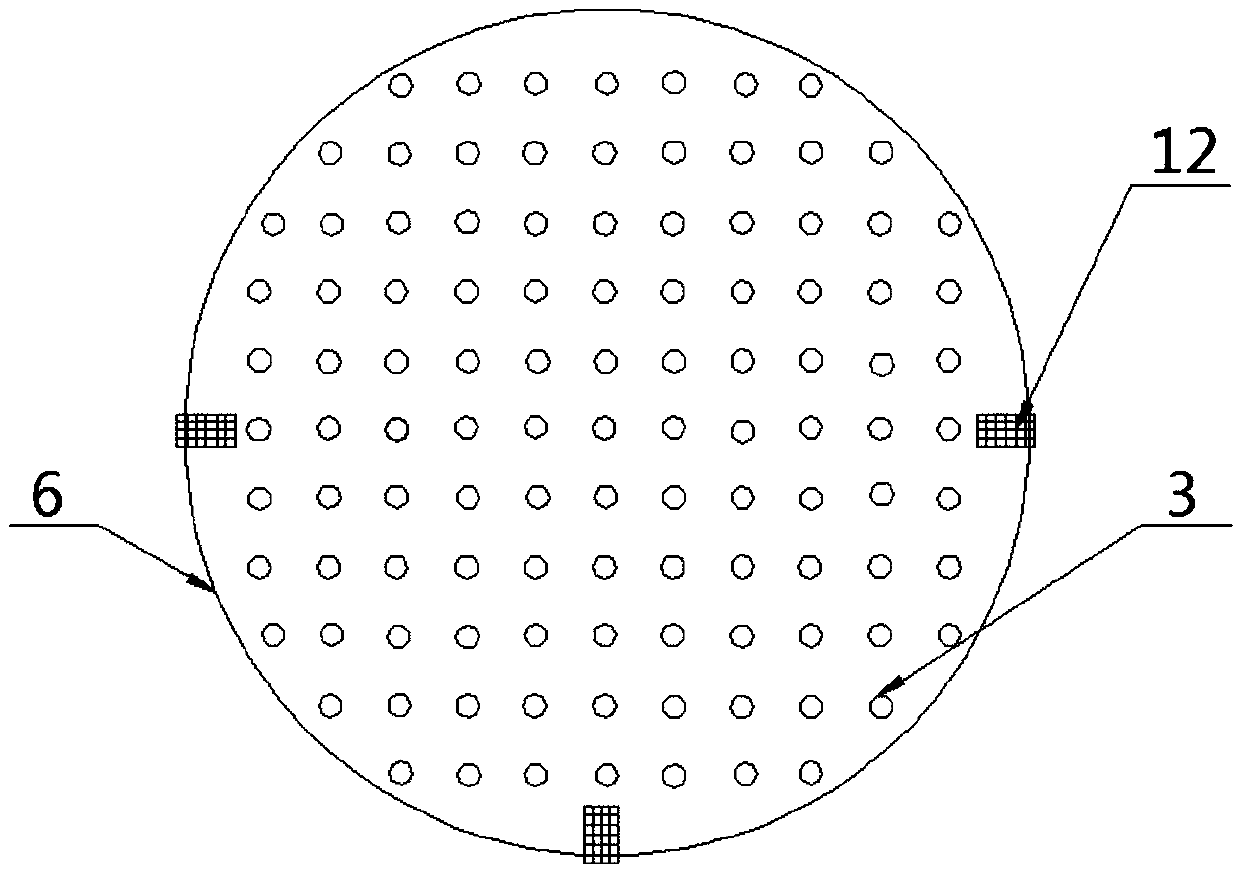

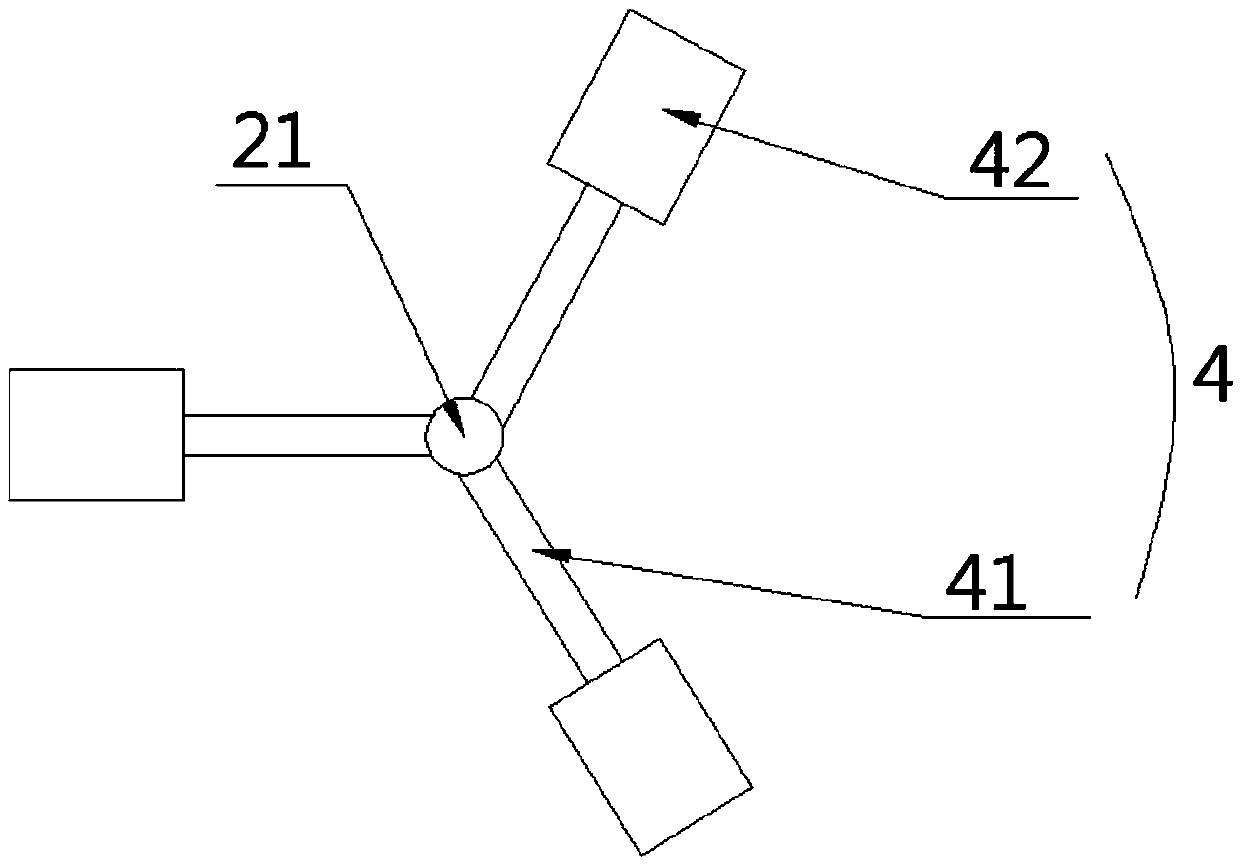

[0017] Such as Figure 1-Figure 3 As shown, a vacuum type PVC stabilizer slice processing line includes a dust suction device, a reaction kettle and a flaking machine x, wherein the top of the reactor is provided with a feeding port 1, and the bottom is provided with a discharge port h. A storage tray y is provided on the flaking machine x, and it is characterized in that: the flaking machine x is located under the reaction kettle, and the reaction kettle and the flaking machine x are connected through a diversion chute z, and the guiding chute The upper end of the flow chute z is located below the outlet h, and the lower end of the flow guide chute z is located above the storage tray y. The dust suction device includes a dust suction hood 6 and an air suction device 8 , the dust suction hood 6 and the suction device 8 are connected by a dust suction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com