Film coating device and film coating method thereof

A technology of film covering device and film device, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., which can solve the problem of small production volume demanders who are not attractive, non-planar products that cannot be filmed, and low production efficiency, etc. problems, to achieve the effects of reducing labor costs, improving film covering efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

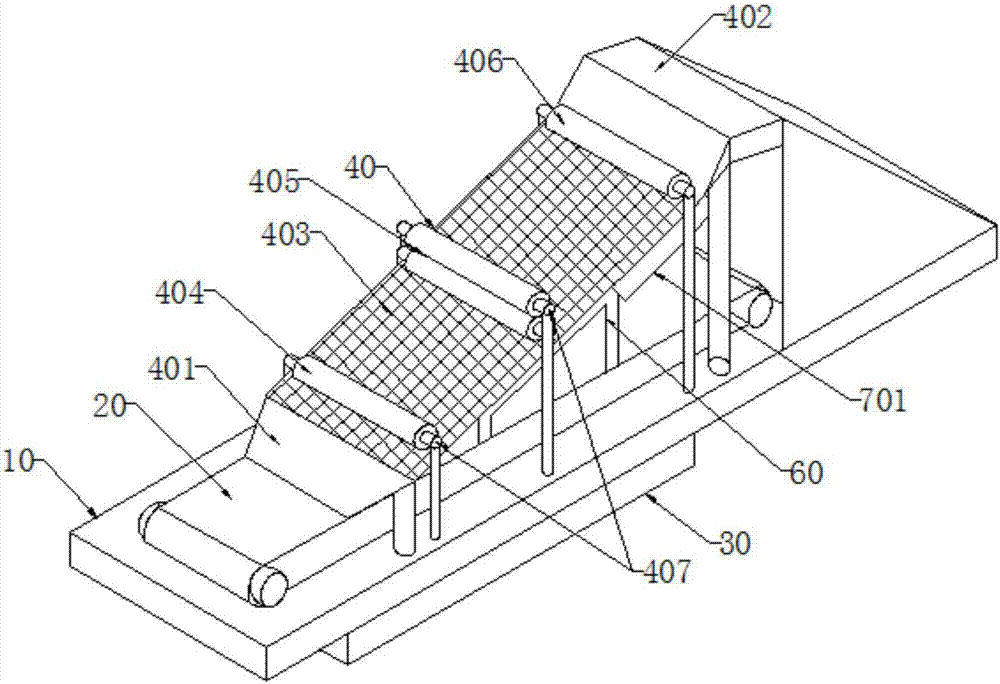

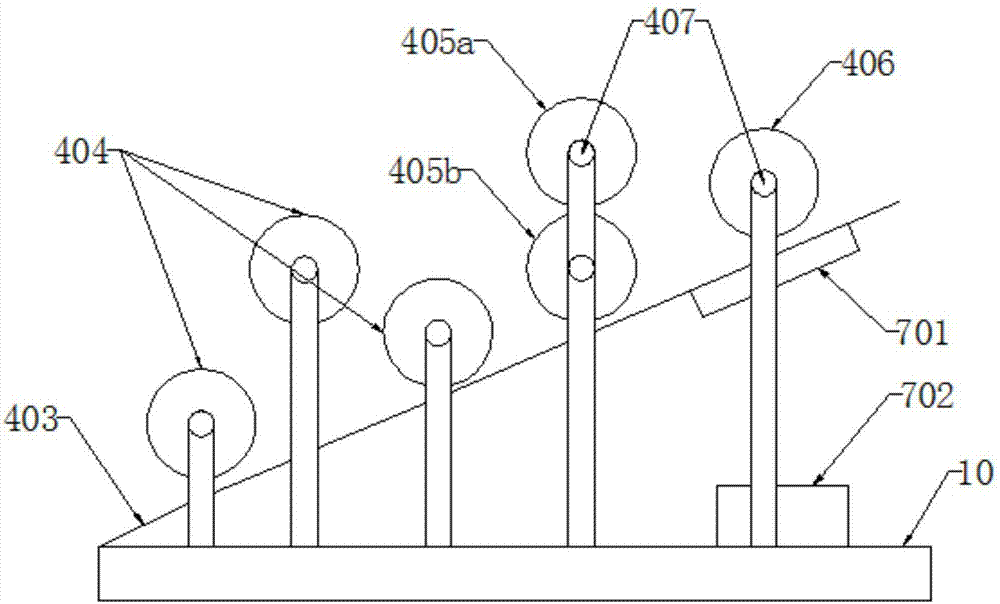

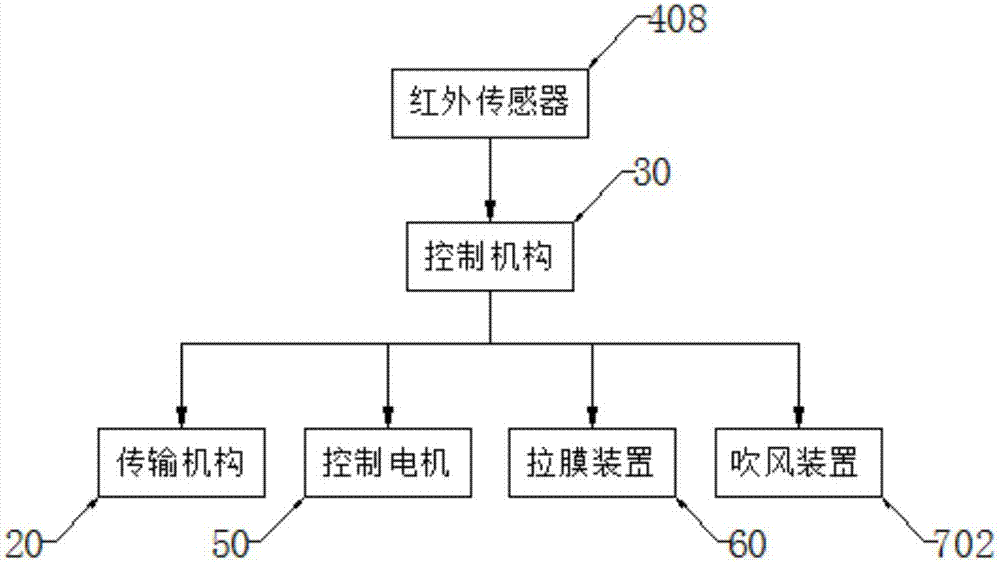

[0042] Such as Figure 1-Figure 3 As shown, a coating device includes a base 10, a transmission mechanism 20, a control mechanism 30 and a coating mechanism 40, the control mechanism 30 is arranged below the base 10, and the transmission mechanism 20 is installed above the base 10 On the surface, the film covering mechanism 40 is arranged above the transmission mechanism 20, and the transmission mechanism 20 runs through the film covering mechanism 40. The film covering mechanism 40 includes a feed port 401, a discharge port 402, a film release plate 403, a flattening roller 404, Laminating roll 405 and auxiliary cooling roll 406, described film release plate 403 has an upward inclination angle of 45°, flattening roll 404, film coating roll 405 and auxiliary cooling roll 406 are located above the film release plate 403 successively, and are close to the film release plate Diaphragm 403; the transmission mechanism 20 moves along the direction of the feed port 401, the feed port...

Embodiment 2

[0044] A film covering device, comprising a base 10, a transmission mechanism 20, a control mechanism 30 and a film covering mechanism 40, the control mechanism 30 is arranged below the base 10, the transmission mechanism 20 is installed on the upper surface of the base 10, the The film covering mechanism 40 is arranged above the transmission mechanism 20, and the transmission mechanism 20 runs through the film covering mechanism 40. The film covering mechanism 40 includes a feed port 401, a discharge port 402, a film release plate 403, a flattening roller 404, and a film covering roller. 405 and auxiliary cooling roller 406, the film releasing plate 403 has an upward inclination of 60°, the flattening roller 404, the laminating roller 405 and the auxiliary cooling roller 406 are sequentially located above the film releasing plate 403, and are close to the film releasing plate 403 The transmission mechanism 20 moves along the feed port 401 direction, the feed port 401 connects ...

Embodiment 3

[0046] A film covering device, comprising a base 10, a transmission mechanism 20, a control mechanism 30 and a film covering mechanism 40, the control mechanism 30 is arranged below the base 10, the transmission mechanism 20 is installed on the upper surface of the base 10, the The film covering mechanism 40 is arranged above the transmission mechanism 20, and the transmission mechanism 20 runs through the film covering mechanism 40. The film covering mechanism 40 includes a feed port 401, a discharge port 402, a film release plate 403, a flattening roller 404, and a film covering roller. 405 and auxiliary cooling roller 406, the film release plate 403 has an upward inclination angle of 50 °, the flattening roller 404, the film roll 405 and the auxiliary cooling roll 406 are located above the film release plate 403 in turn, and are close to the film release plate 403 The transmission mechanism 20 moves along the feed port 401 direction, the feed port 401 connects the entrance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com