Drying equipment and application thereof

A technology of drying equipment and equipment, applied in liquid spraying device, pretreatment surface, spraying device, etc., can solve problems such as poor coating firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

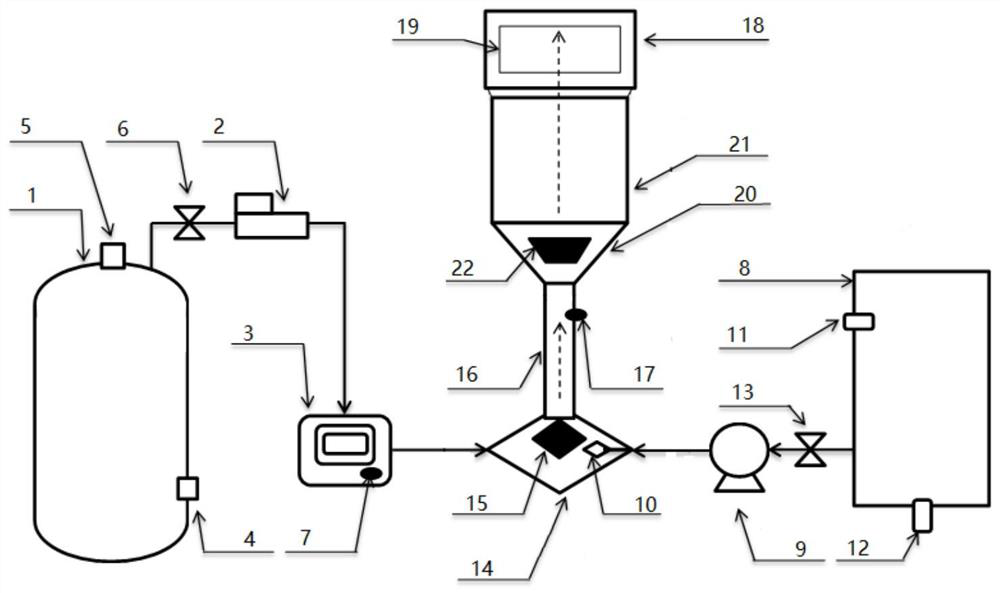

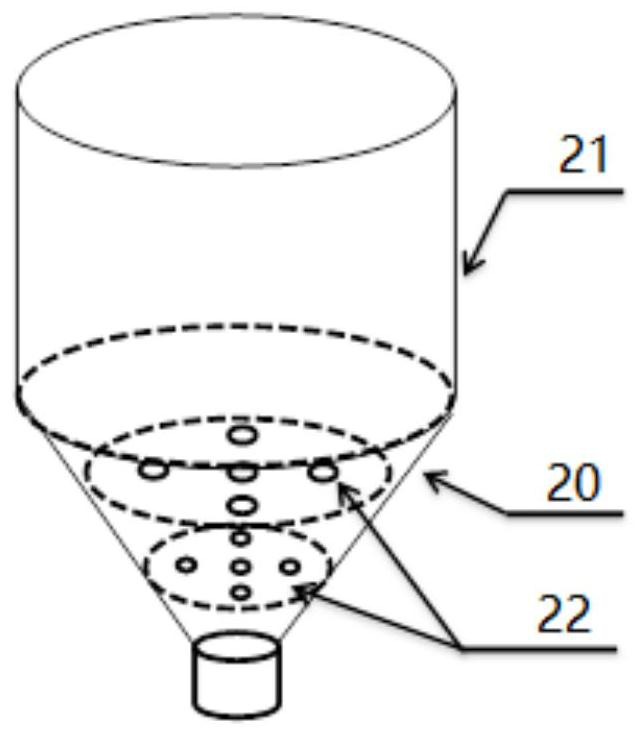

Method used

Image

Examples

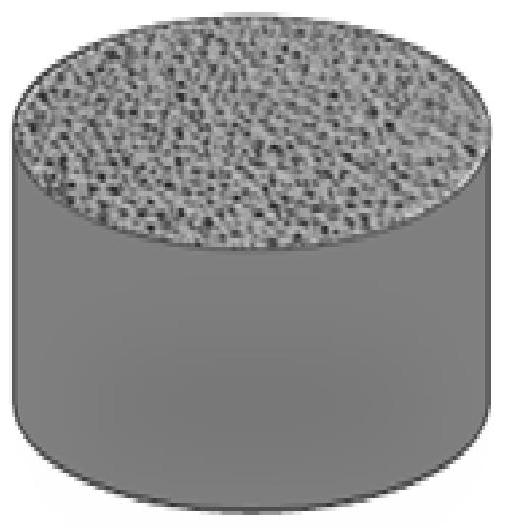

Embodiment 1

[0086] Preparation of washcoat slurry: select a cylindrical honeycomb metal substrate with a size of 400cpsi The alumina slurry coating is loaded by the slurry coating method, the coating load is about 15% of the mass of the honeycomb metal substrate, and the drying equipment of the present invention is used for drying treatment, and the sample is marked as Example-1.

[0087] Drying process parameters: the temperature is 90°C, the relative humidity is 85%, and the drying time is 15 minutes.

Embodiment 2

[0089] Preparation of washcoat slurry: same as in Example 1, the sample is marked as Example-2.

[0090] Drying process parameters: the temperature is 90°C, the relative humidity is 60%, and the drying time is 15 minutes.

Embodiment 3

[0092] Preparation of washcoat slurry: same as in Example 1, the sample is marked as Example-3.

[0093] Drying process parameters: the temperature is 90°C, the relative humidity is 35%, and the drying time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com