A plastering mortar of modified recycled rubber aggregate

A rubber aggregate and plastering mortar technology, which is applied in the field of external wall insulation mortar and plastering mortar, can solve problems such as cracks in the external thermal insulation system, hollowing of the external thermal insulation layer, and large amount of cement, so as to protect the environment, improve toughness, and improve The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The invention uses modified regenerated rubber for the external wall thermal insulation mortar to prepare new external wall thermal insulation mortar.

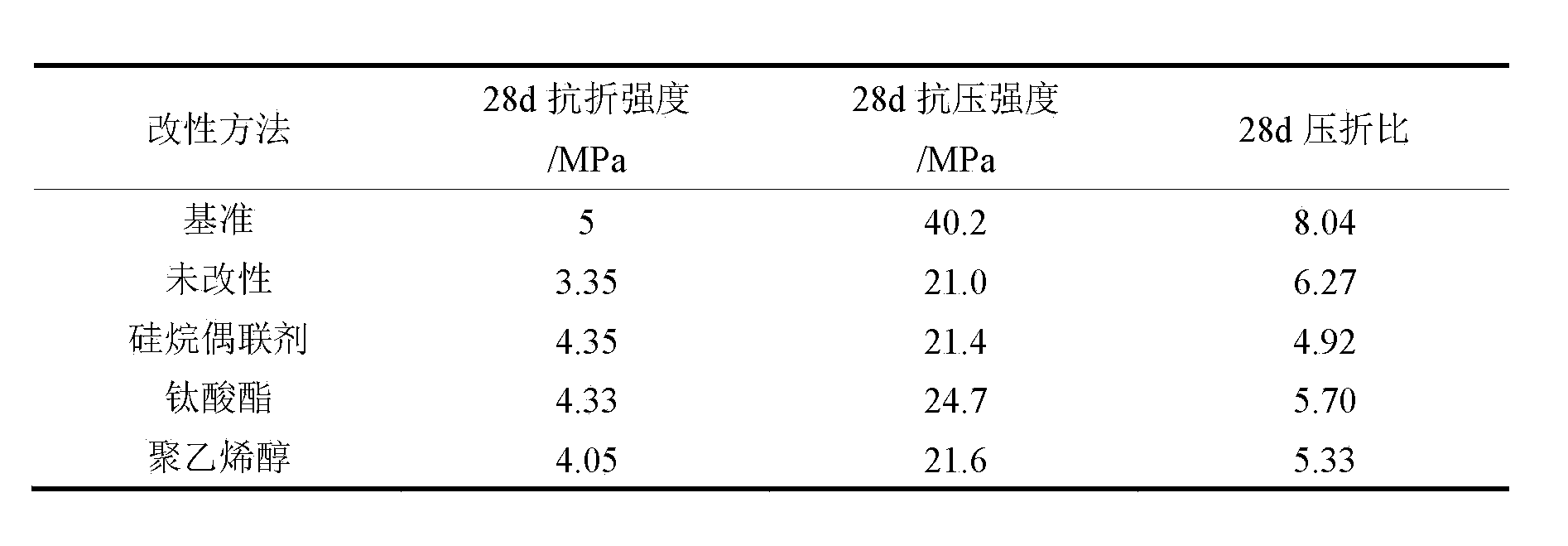

[0016] The preparation method of modified rubber aggregates: Weigh 35~50Kg of rubber aggregates with a particle size of 60 mesh and a silane coupling agent with a mass concentration of 2% of the rubber aggregates, add it to alcohol with a mass concentration of 95%, and make a coupling Coupling agent alcohol solution, fully wet the rubber aggregate particles with the coupling agent alcohol solution, stir evenly, and let it stand until the surface of the rubber aggregate particles is completely dry before use.

[0017] The weight of each component of mortar per ton is: P.O42.5 cement: 310Kg, washed fine sand: 690 Kg, redispersible latex powder (copolymer of vinyl acetate and ethylene): 10~15Kg; hydroxypropyl methyl Cellulose ether: 1.5~2.5Kg; polypropylene fiber with a fiber length of 6mm: 1Kg; modified rubber aggregate: ...

Embodiment 2

[0020] The invention uses modified regenerated rubber for the external wall thermal insulation mortar to prepare new external wall thermal insulation mortar.

[0021] The preparation method of modified rubber aggregates: take a polyvinyl alcohol solution with a mass concentration of 1%, fully soak the rubber aggregates for 1-2 hours, take out the soaked rubber aggregates, and wait until the surface of the rubber aggregate particles is completely dry. use.

[0022] The weight of each component of mortar per ton is: P.O42.5 cement: 380Kg, washed fine sand: 600 Kg, redispersible latex powder (copolymer of vinyl acetate and ethylene): 10~15Kg; hydroxypropyl methyl Cellulose ether: 1.5~2.5Kg; polypropylene fiber with a fiber length of 6mm: 1Kg; modified rubber aggregate: 35~50Kg.

[0023] Step 1: Stir water, redispersible latex powder, hydroxypropyl methyl cellulose ether, polypropylene fibers and rubber aggregates for 30 seconds. Step 2: Add cement and stir for 30 seconds. Step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com