A preparation method of low-shrinkage, high-hardness, high-wear-resistant transparent polyimide hardened film

A technology of transparent polyimide and hardened film, used in polyether coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of other failures, screen crease damage, volume shrinkage, etc., to avoid warpage , reducing and warping, reducing the effect of volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

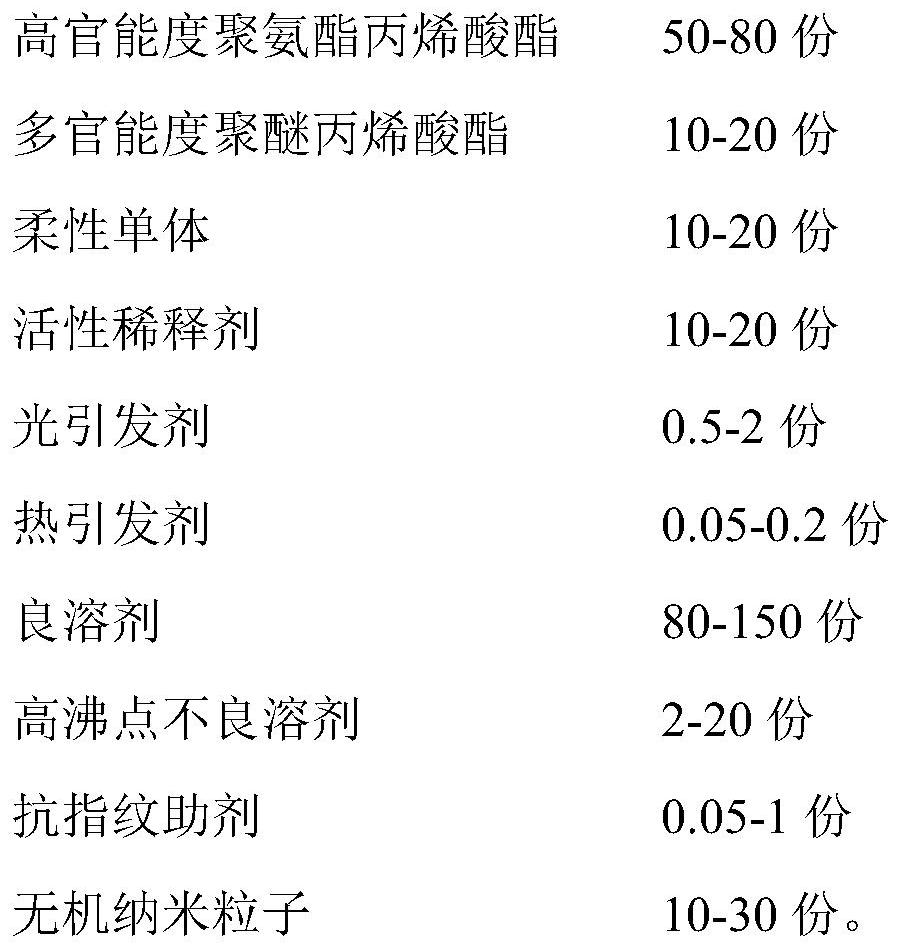

Method used

Image

Examples

Embodiment Construction

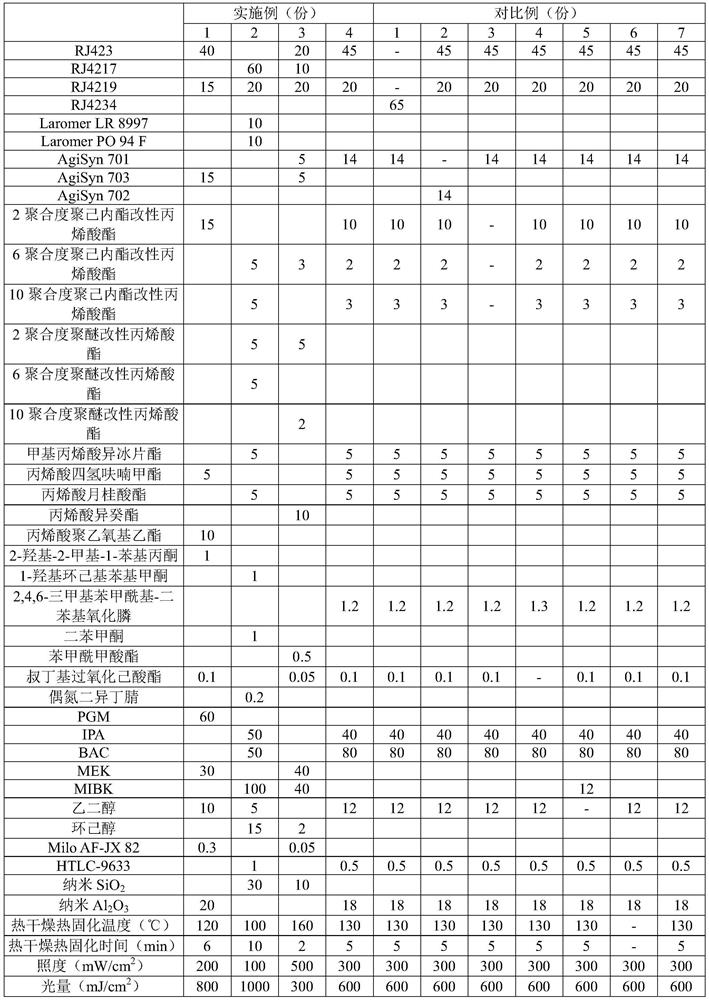

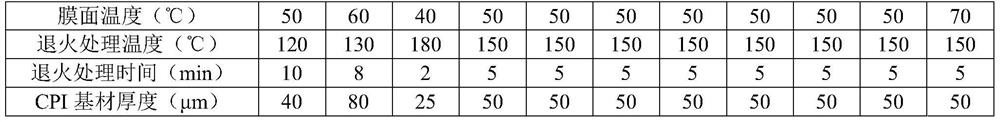

[0022] The present invention is described in further detail now in conjunction with embodiment.

[0023] The high-functionality urethane acrylate used in this application is 6-functionality urethane acrylate (RJ423), 9-functionality urethane acrylate (RJ4217) and 15-functionality urethane acrylate (RJ4219); The acrylates are BASF's 3.4-functionality polyether acrylate (Laromer LR 8997) and 3.5-functionality polyether acrylate (Laromer PO 94F), and DSM's 4-functionality polyether acrylate (AgiSyn 701) and 4-functionality Polyether acrylate (AgiSyn 703); anti-fingerprint additives are Milo AF-JX 82 perfluoropolyether anti-fingerprint oil and perfluoropolyether anti-fingerprint oil additive HTLC-9633.

[0024] The urethane acrylate used in the comparative example is the 2-functional urethane acrylate (RJ4234) of Liangzhi Chemical; the multi-functional polyether acrylate used in the comparative example is the 2-functional polyether acrylate (AgiSyn 702) of DSM.

[0025] The prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com