Preparation method of anti-cracking high-strength board materials

A high-strength, anti-cracking technology, applied in the direction of manufacturing tools, impregnated wood, wood impregnation, etc., can solve the problems of furniture aesthetics, poor consistency, short service life, easy aging, etc., to improve surface crack resistance and improve surface quality. Quality, effect of shrinkage stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

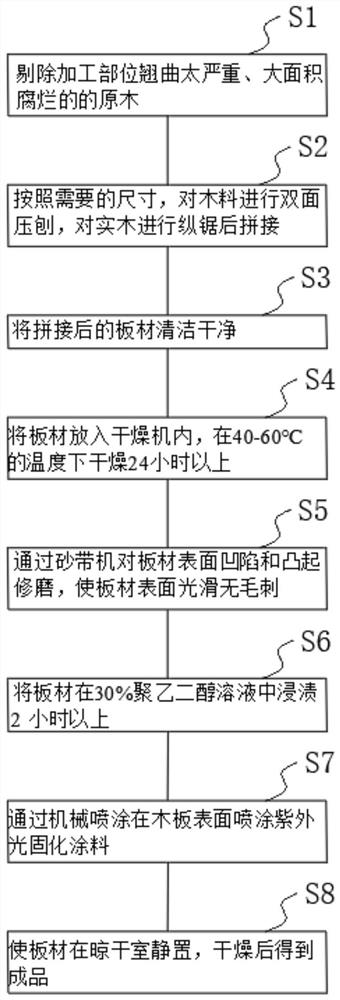

[0035] Such as figure 1 Shown, a kind of preparation method of anti-cracking high-strength plate comprises the following steps:

[0036] S1. Screening,

[0037] Remove the logs that are too warped or rotted in a large area at the processing part, and cut off the materials with uneven ends.

[0038] Screen the quality of processed parts such as: too serious warping (ultimately affecting the product effect), large area of decay (no space for processed parts)

[0039] S2. Stitching,

[0040] According to the required size, double-sided planing is carried out on the wood. The planing amount generally does not exceed 1cm each time. When passing through the planing mouth, the force should be light, and it is strictly forbidden to return the material above the planer; when encountering knots, slow down the pushing speed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com