A kind of nanocrystalline cemented carbide and preparation method thereof

A cemented carbide and nanocrystalline technology, which is applied in the field of nanocrystalline cemented carbide for railway line maintenance and screen cleaning locomotives and its preparation, can solve the problems of increased Rockwell hardness and decreased toughness of cemented carbide, and achieves high impact toughness, The effect of eliminating shrinkage stress, high hardness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] According to the present invention, a preparation method of nanocrystalline cemented carbide is also provided, wherein the preparation method comprises the following steps:

[0022] (1) The mixed particles of coarse-grained tungsten carbide, nano-grained tungsten carbide and cobalt powder are subjected to mechanical compression molding;

[0023] (2) sintering the mixed particles formed in step (1) under pressure of an inert gas;

[0024] (3) After the sintering treatment in step (2), the secondary sintering treatment is performed;

[0025] Wherein, the amount of coarse-grained tungsten carbide, nano-grained tungsten carbide and cobalt powder is such that the prepared nanocrystalline cemented carbide can contain 55-75% by weight of coarse-grained tungsten carbide and 15-25% by weight of nanoparticles Tungsten carbide and cobalt powder may contain 10-20% by weight.

[0026] According to the present invention, the amount of the coarse-grained tungsten carbide, the nano-g...

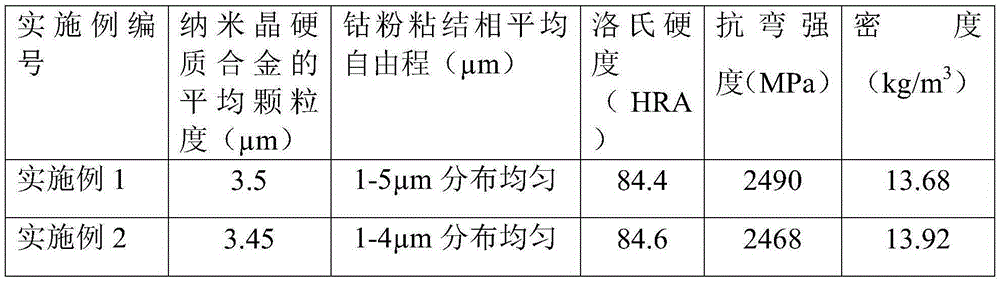

Embodiment 1

[0038] Step (1): The mixed particles of coarse-grained tungsten carbide with a grain size of 12 μm, nano-particle tungsten carbide with a grain size of 0.64 μm and cobalt powder with a grain size of 0.3 μm were prepared at a pressure of 1200 kg / cm 2 Under mechanical pressure forming treatment;

[0039] Step (2): The mixed particles formed in step (1) are sintered under the inert gas nitrogen, under the pressure of the inert gas pressure of 4.7MPa, the sintering temperature is 1435°C, and the sintering time is 115 minutes. ;

[0040] Step (3): after the sintering treatment in step (2), sintering treatment at a temperature of 1395 ° C for 50 minutes;

[0041] Wherein, the amount of coarse-grained tungsten carbide, nano-grained tungsten carbide and cobalt powder is such that the prepared nanocrystalline cemented carbide contains 60 wt % of coarse-grained tungsten carbide, 23 wt. % of nano-grained tungsten carbide and 17 wt. % cobalt powder.

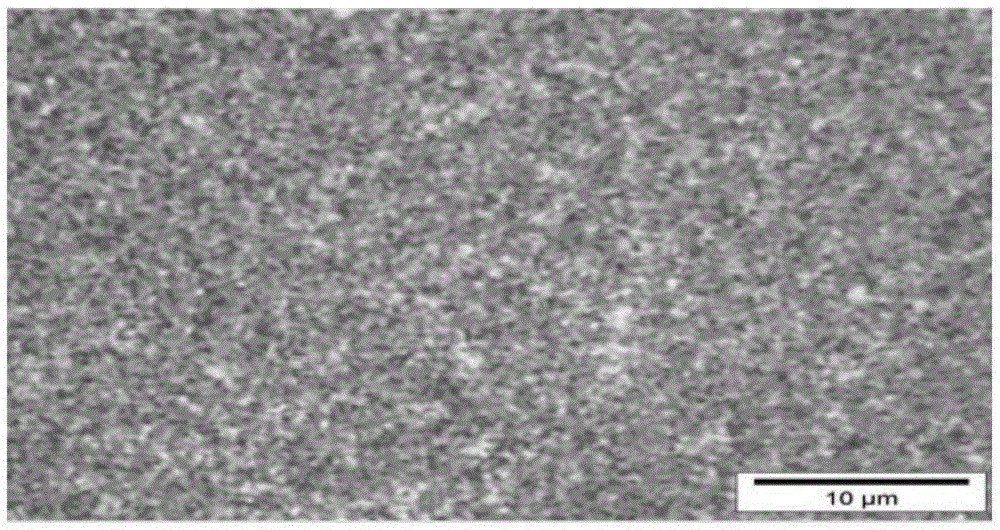

[0042] figure 1It is a metallogra...

Embodiment 2

[0046] Step (1): The mixed particles of coarse-grained tungsten carbide with a grain size of 14 μm, nano-particle tungsten carbide with a grain size of 0.68 μm and cobalt powder with a grain size of 0.8 μm were prepared at a pressure of 1800 kg / cm 2 Under mechanical pressure forming treatment;

[0047] Step (2): The mixed particles formed in step (1) are sintered under the inert gas nitrogen, under the pressure of the inert gas pressure of 4.5 MPa, the sintering temperature is 1445 ° C, and the sintering time is 125 minutes. ;

[0048] Step (3): after the sintering treatment in step (2), sintering treatment at a temperature of 1405 ° C for 70 minutes;

[0049] Wherein, the amount of coarse-grained tungsten carbide, nano-grained tungsten carbide and cobalt powder is such that the prepared nanocrystalline cemented carbide contains 70 wt % of coarse-grained tungsten carbide, 18 wt. % of nano-grained tungsten carbide and 12 wt. % cobalt powder.

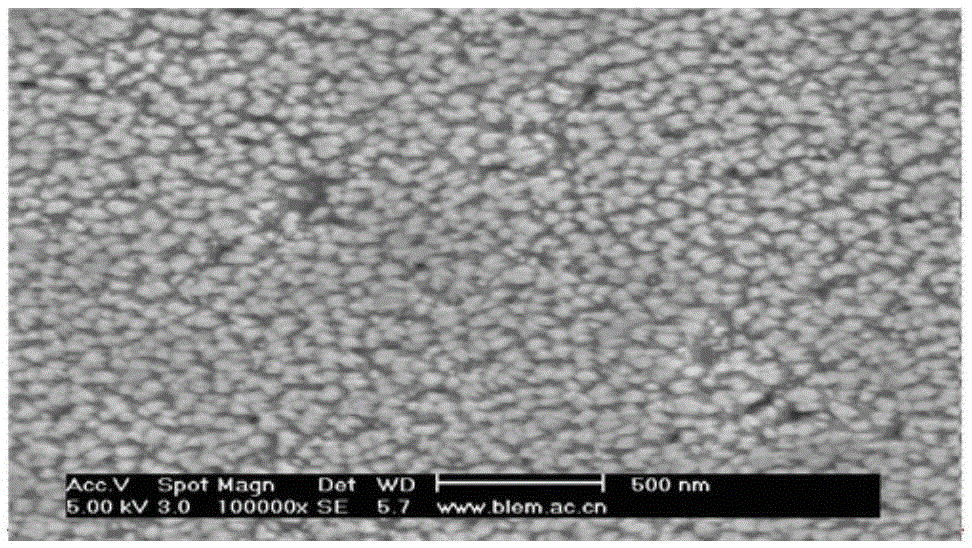

[0050] The average particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com