Multi-blade stirring-type dust collecting reaction system

A reaction system, stirring technology, applied in chemical/physical/physical-chemical stationary reactors, removing smoke and dust, dispersing particle filtration, etc. Harm and other problems, to avoid the flying of powdery raw materials, to ensure health, and to reduce the loss rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

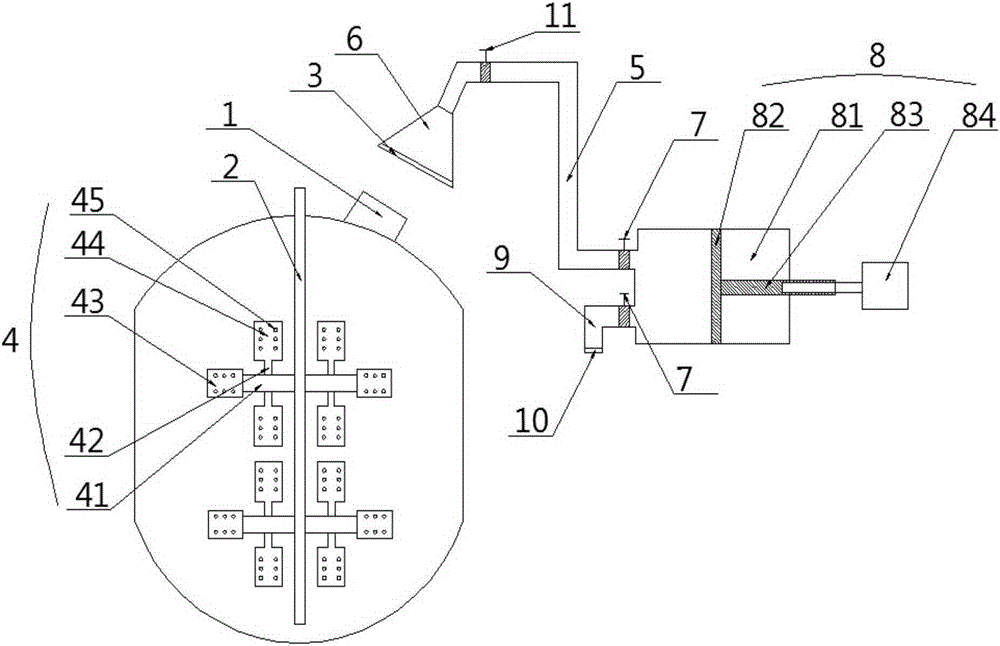

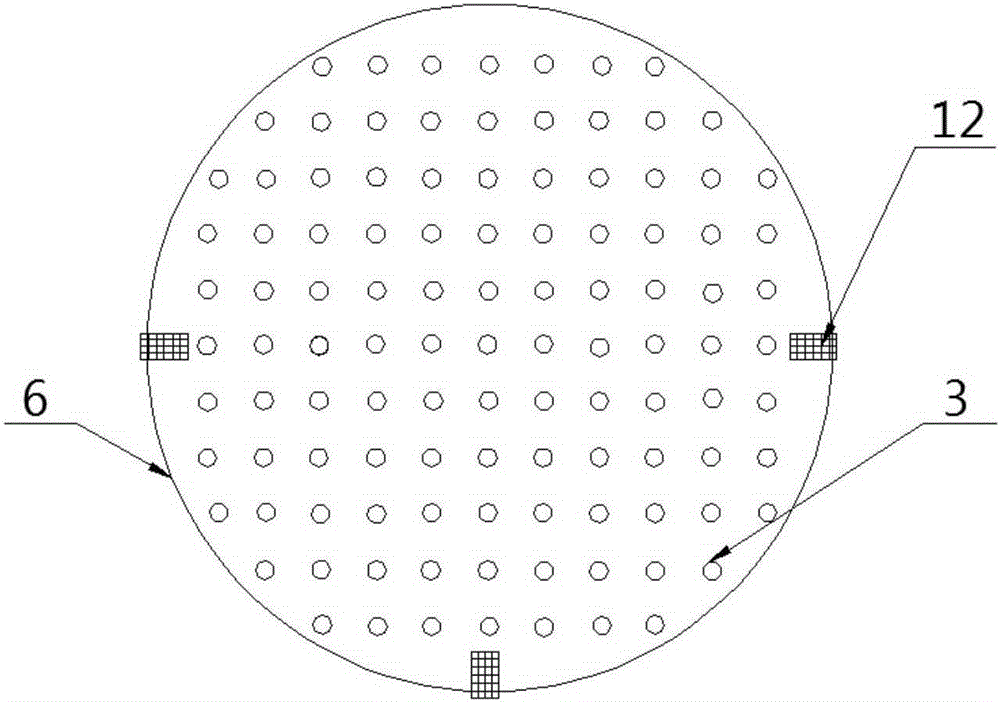

[0015] Such as figure 1 , 2 Shown, a kind of multi-leaf agitation type dust suction reaction system comprises a dust suction device and a reactor, wherein the top of the reactor is provided with a feeding port 1, and the dust suction device includes a dust suction hood 6 and an air extraction device 8, so The dust suction hood 6 is connected with the suction device 8 through a dust suction pipe 5 , and the dust suction hood 6 is located above the feeding port 1 .

[0016] The reactor is provided with a stirring main shaft 2, and the top of the stirring main shaft 2 protrudes from the reactor, and two sets of stirring paddles 4 are installed on the stirring spindle 2, and the stirring paddles 4 include horizontal connecting rods arranged horizontally. 41 and two longitudinal connecting rods 42, the middle part of the transverse connecting rod 41 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com