Drive structure and control method of switched reluctance motor based on three-level inverter

A technology of switched reluctance motors and three-level inverters, applied in the direction of AC motor control, control systems, electrical components, etc., can solve the problems of not being able to adapt to different working conditions, restricting control flexibility, and being unable to adjust in real time, to achieve The effect of improving safety and reliability, reducing difficulty of selection, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

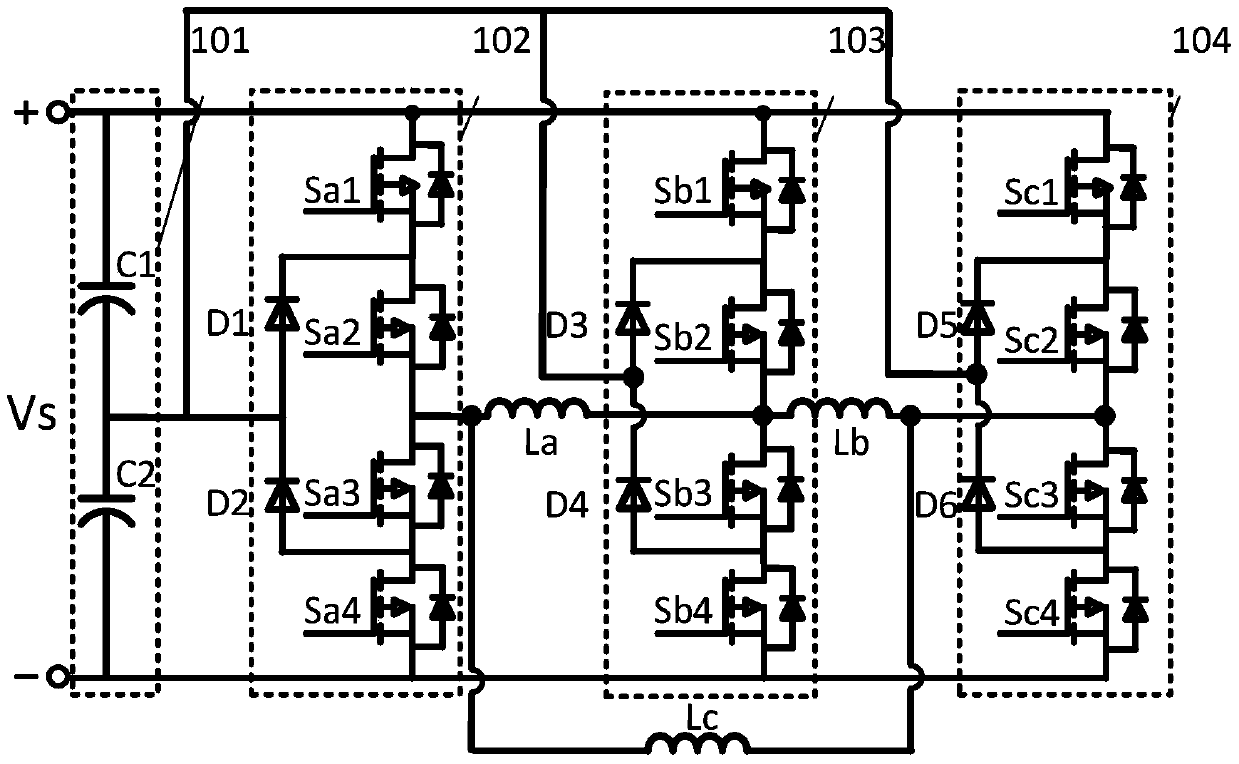

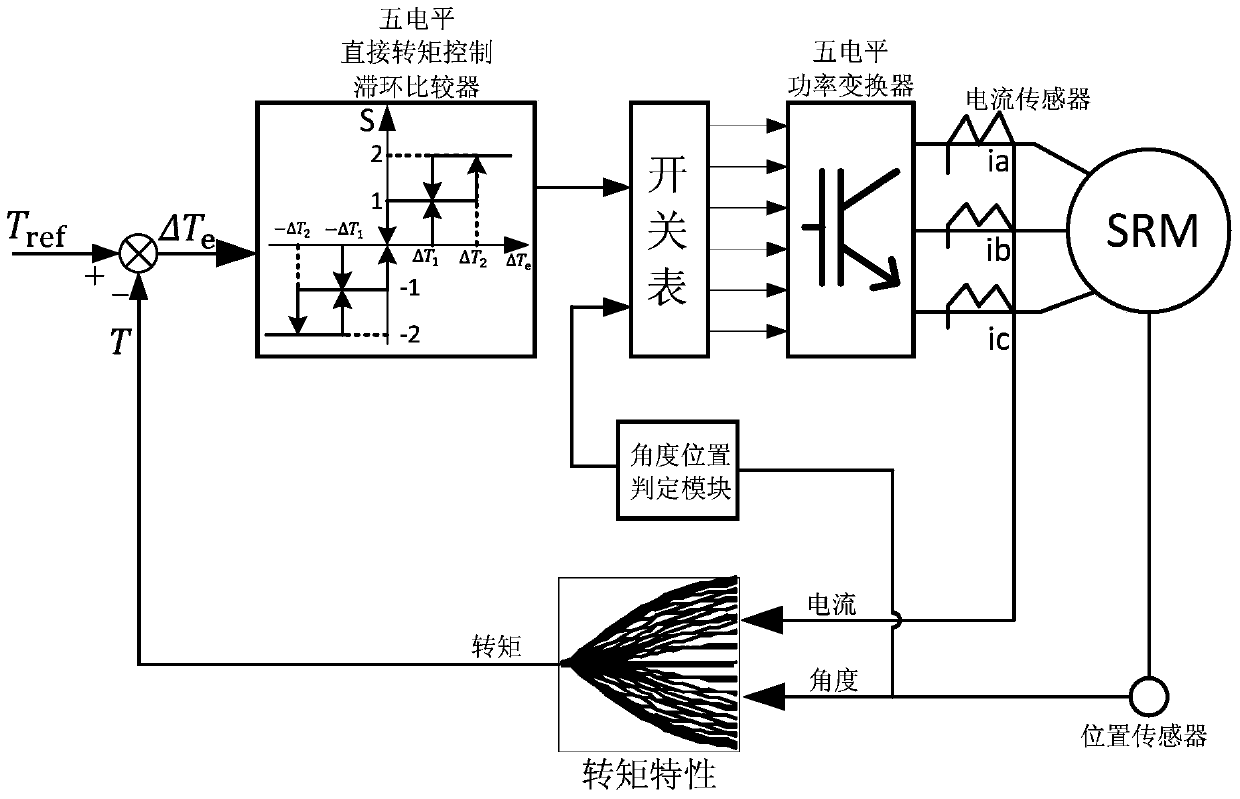

[0063] Combine below figure 1 and image 3 Illustrate the specific embodiment of the present invention:

[0064] The driving structure of a switched reluctance motor based on a three-level inverter described in this embodiment is as follows: figure 1 As shown, it includes a power supply Vs, a switched reluctance motor phase A winding La, a switched reluctance motor phase B winding Lb, a switched reluctance motor phase C winding Lc, a capacitor module 101, a first bridge arm 102, and a second bridge arm 103 , the third bridge arm 104;

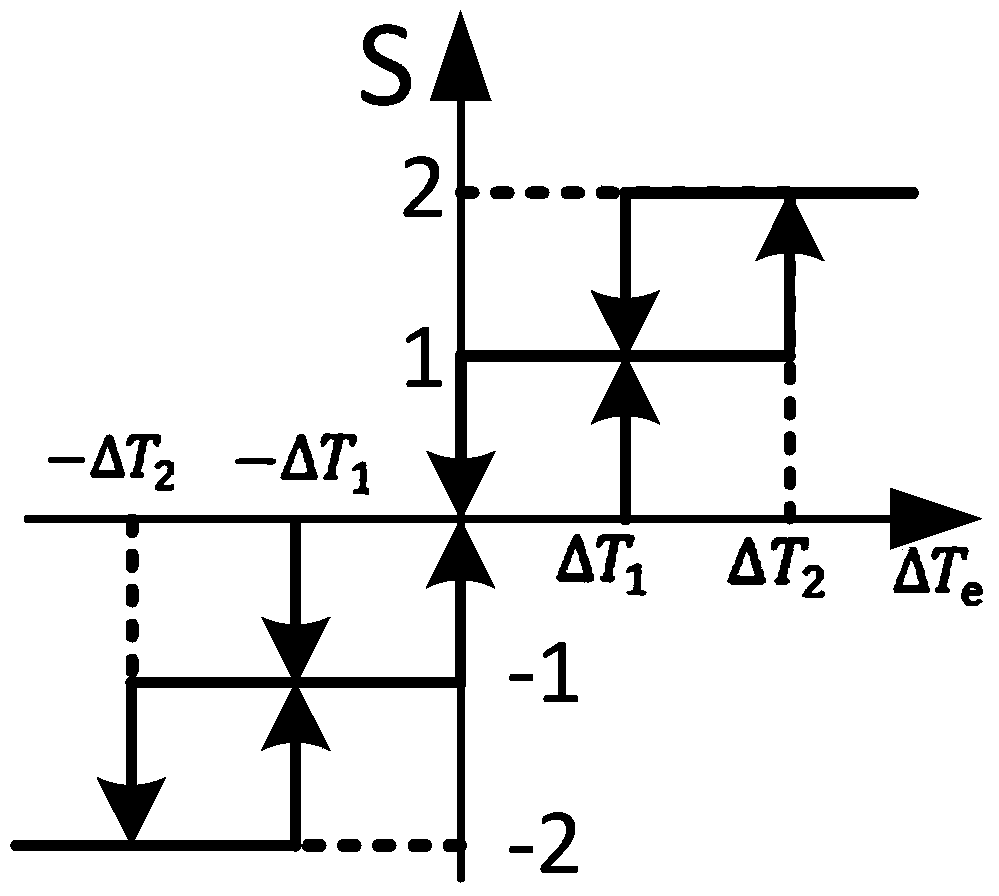

[0065] Figure 1 ~ Figure 3 The middle symbols respectively represent: Vs is the input power supply, which is the main power supply for the motor; Sa1, Sa2, Sa3, and Sa4 are the four switching tubes with anti-parallel diodes of the first bridge arm 102; Sb1, Sb2, Sb3, and Sb4 are Four switch tubes with anti-parallel diodes in the second bridge arm 103; Sc1, Sc2, Sc3, Sc4 are four switch tubes with anti-parallel diodes in the third bridge arm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap