Half shell bearing

A technology for bearings and bearing shells, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems affecting the functionality of half-shell bearings, damage to bearing shells or cages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

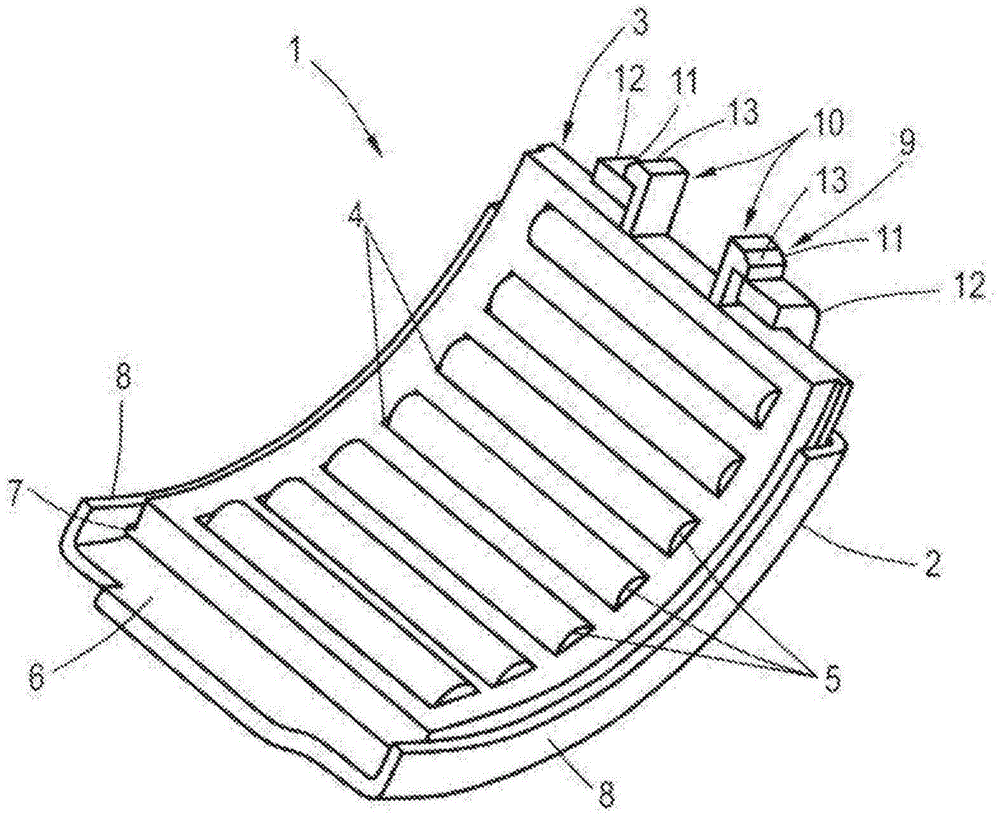

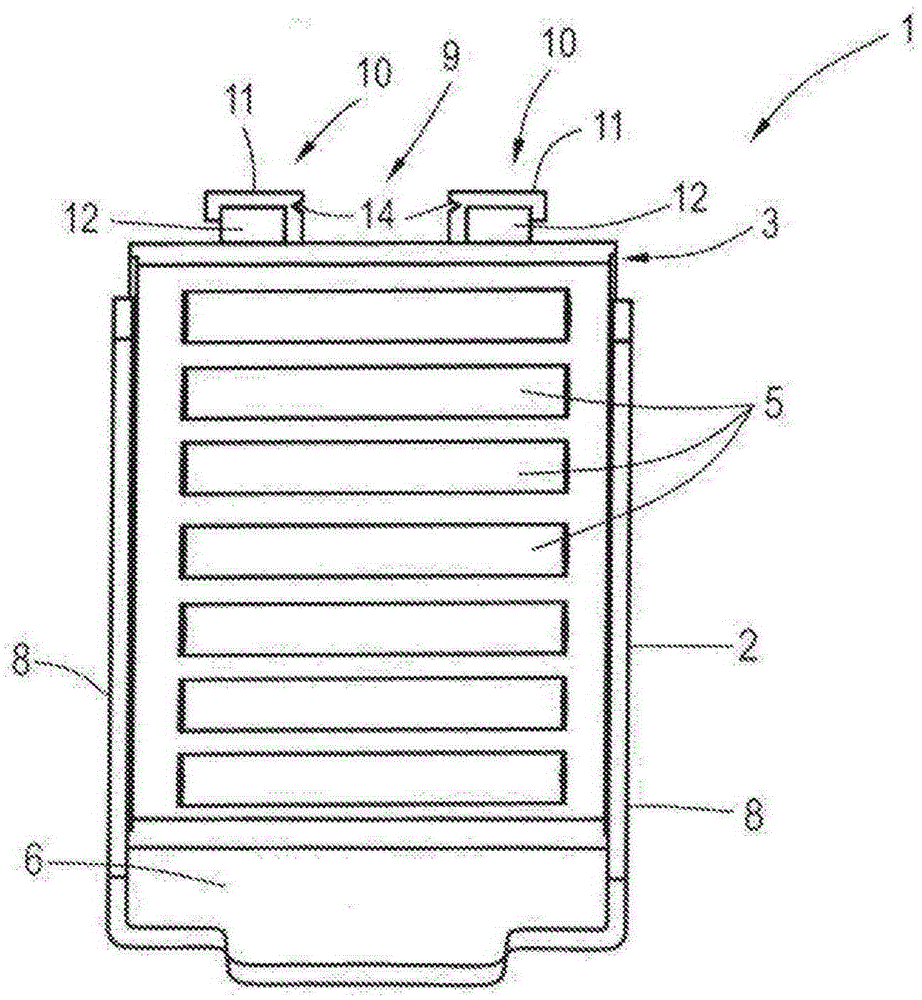

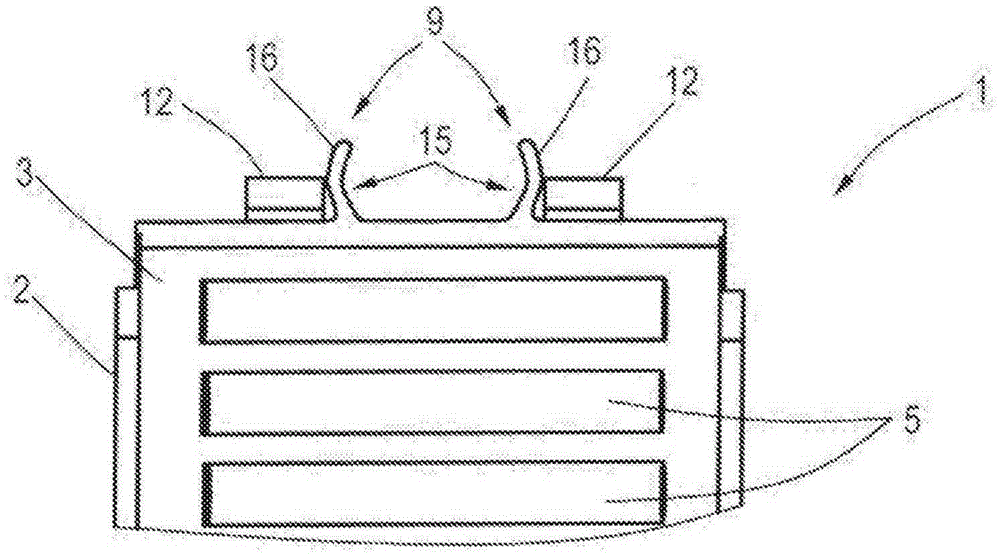

[0022] figure 1 A half-shell bearing 1 according to the invention is shown in a first embodiment, comprising a bearing shell 2 , usually made of metal or sheet metal, in which a cage 3 , usually made of plastic, is accommodated. In the cage, rolling bodies 5 in the form of rollers are accommodated in the respective receptacles 4 . When the half-shell bearing 1 according to the invention is assembled via the bearing shell 2 on a housing or other component, usually by press-fitting or the like, the rolling bodies 5 roll on the inside 6 of the half-shell 2 forming the running surface. In the assembled position or in operation, the cage 3 can be moved along the raceway defined by the curved half-shells 2 , so that a component mounted via the rolling elements 5 , such as a brake lever or similar, pivots. The rod is supported accordingly.

[0023] On the one hand, the cage 3 is radially stopped to prevent it from falling off. For this reason, corresponding axially protruding tabs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com