Anti-overflowing stirring cylinder

A mixing tank and anti-overflow technology, which is applied to mixer accessories, mixers with rotating mixing devices, and dissolving directions, can solve the problems of influence, easy deterioration of chemical raw materials, easy spillage of chemical raw materials, etc., and achieves good shading effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For ease of description, in the present invention, liquid chemical raw materials are referred to as liquid for short; the external stirring shaft is also the stirring shaft on the disperser 1 .

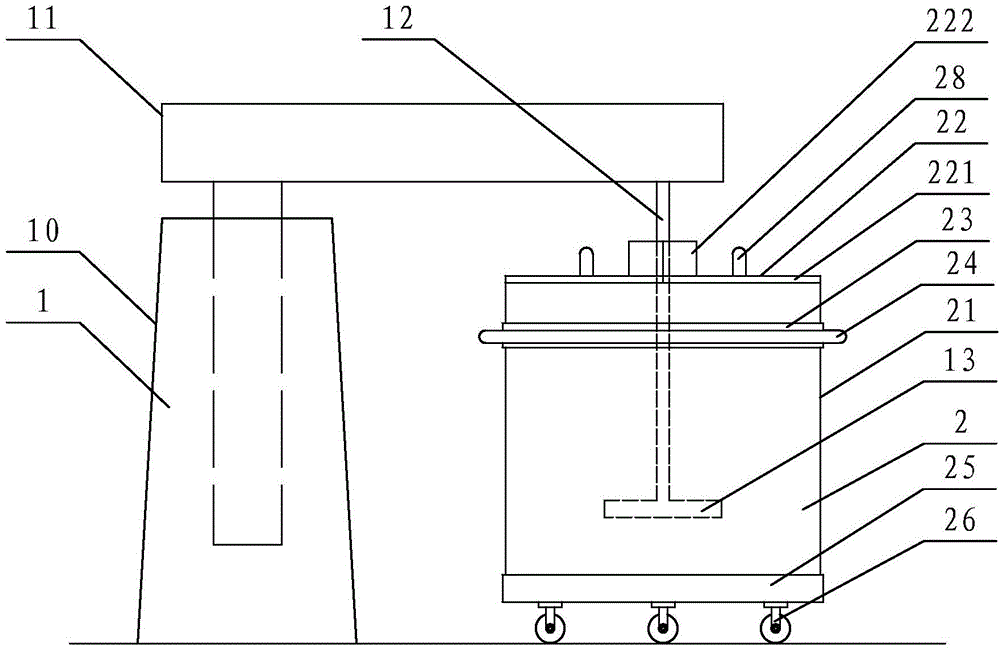

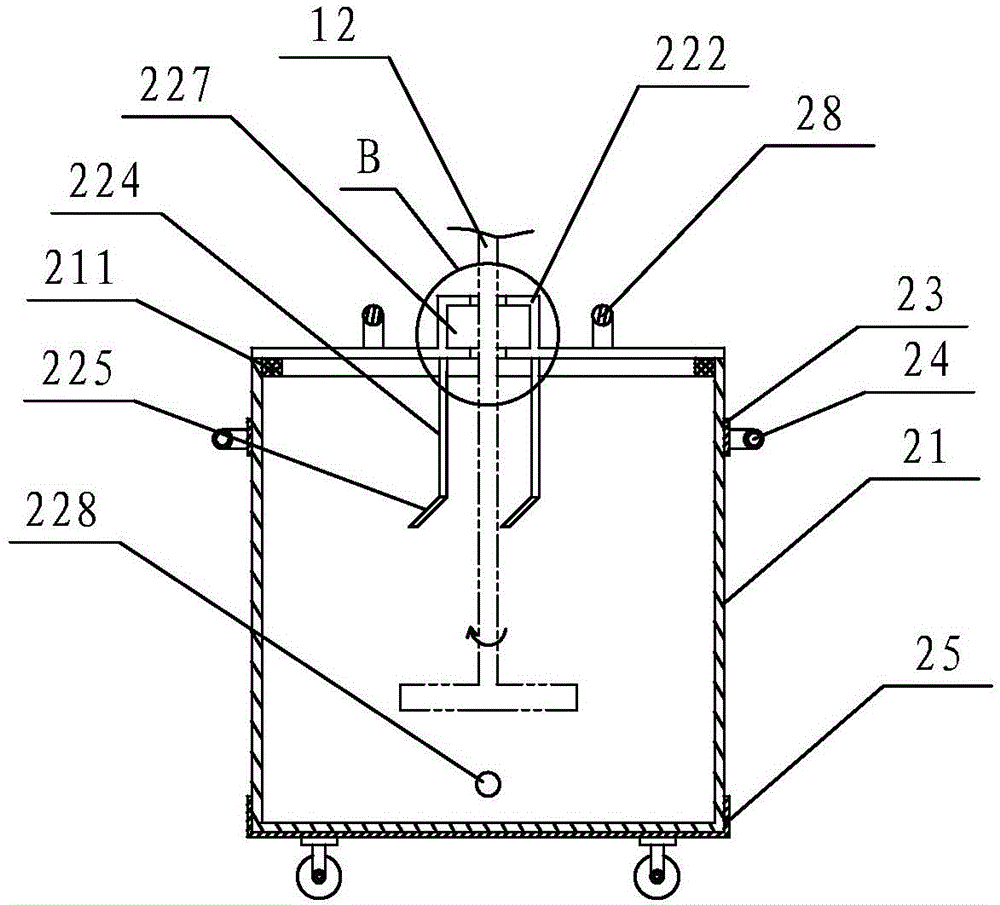

[0028] Such as figure 1 As shown, the anti-overflow mixing cylinder 2 of the present invention is mainly used for matching with the disperser 1 in the prior art, and the base 10 of the disperser 1 in the prior art is provided with a liftable beam 11 and is arranged on The stirrer on the free end of the beam 11, the stirrer comprises a stirring shaft 12 and a stirring paddle 13, the stirring shaft 12 connects the stirring paddle 13 and the cross beam 11, and drives the stirring paddle 13.

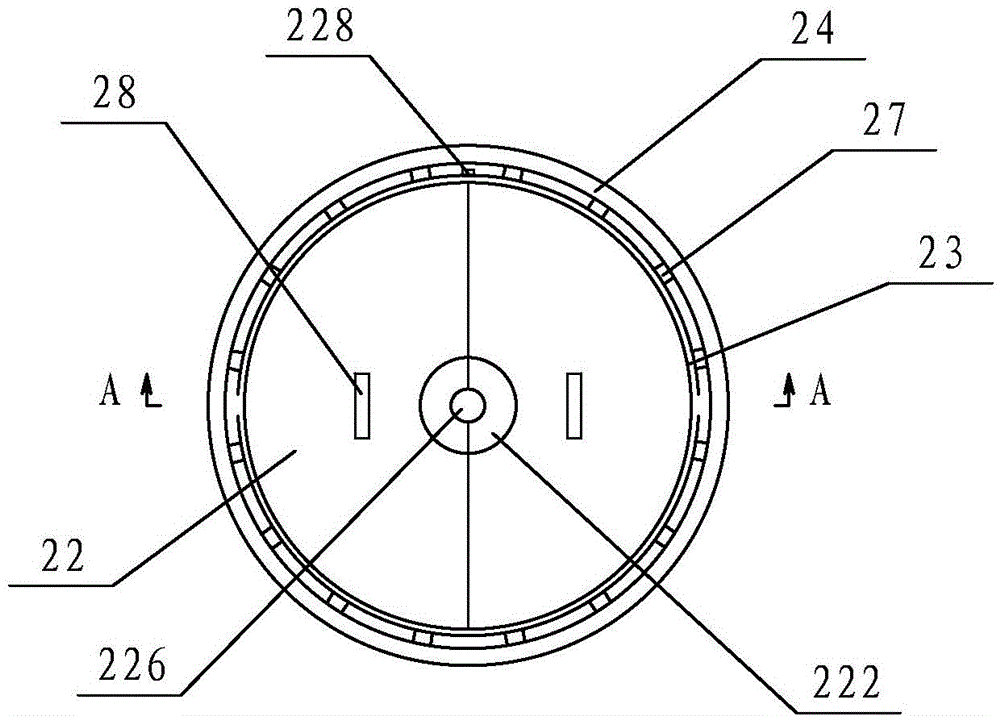

[0029] Such as Figure 1-Figure 8 The shown anti-overflow mixing cylinder 2 includes a cylinder body 21 with an open top and a cylinder cover 22 that covers the top of the cylinder body 21 . The cylinder head 22 includes a plate-shaped cover body 221 and an annular protrusion 222 disposed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com