Mixing device for gas-liquid two-phase annular flow jet flow and main flow gas

An annular flow, gas-liquid mixer technology, which is applied in the directions of liquid injection devices and injection devices, can solve the problems of complex flow state, compact design and economic limitations, and no gas-liquid two-phase jet form is found. Achieve the effect of intensifying crushing and atomization, enhancing instability, and enhancing blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

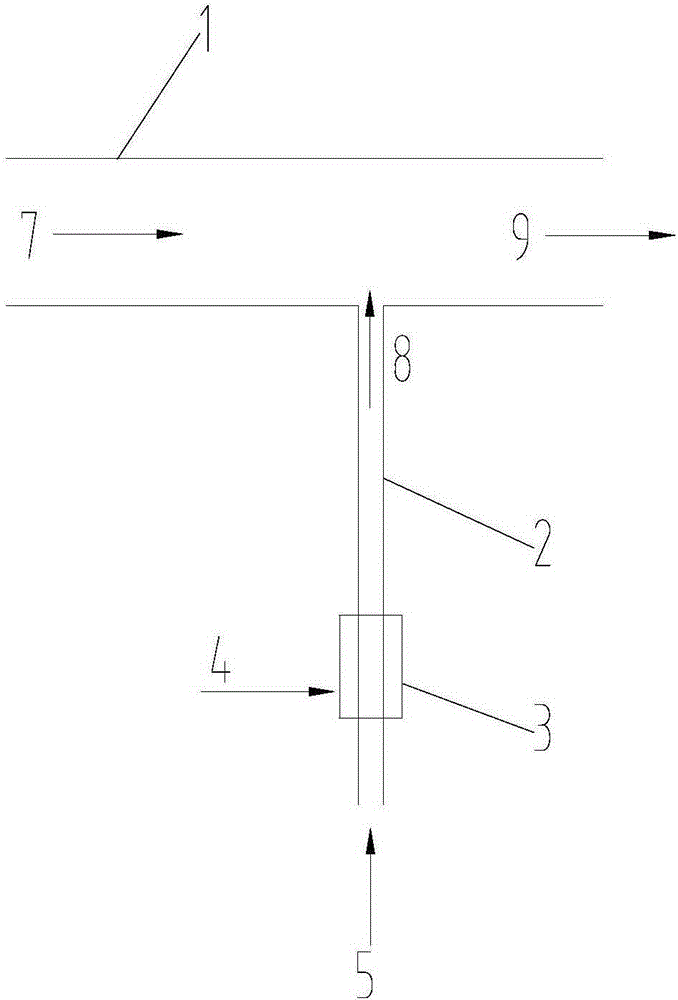

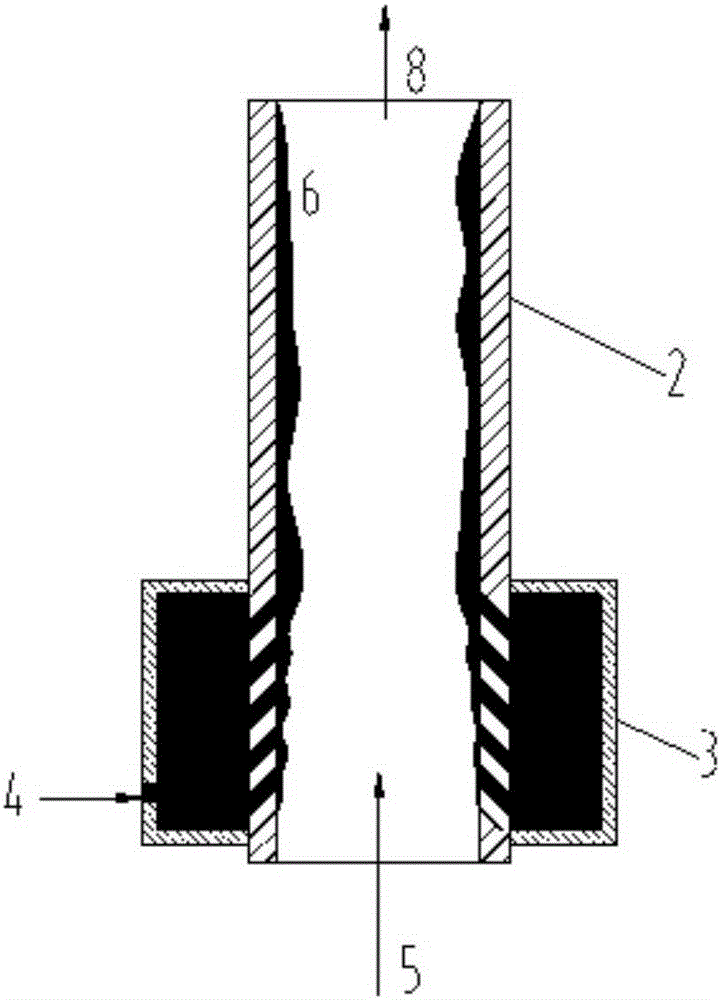

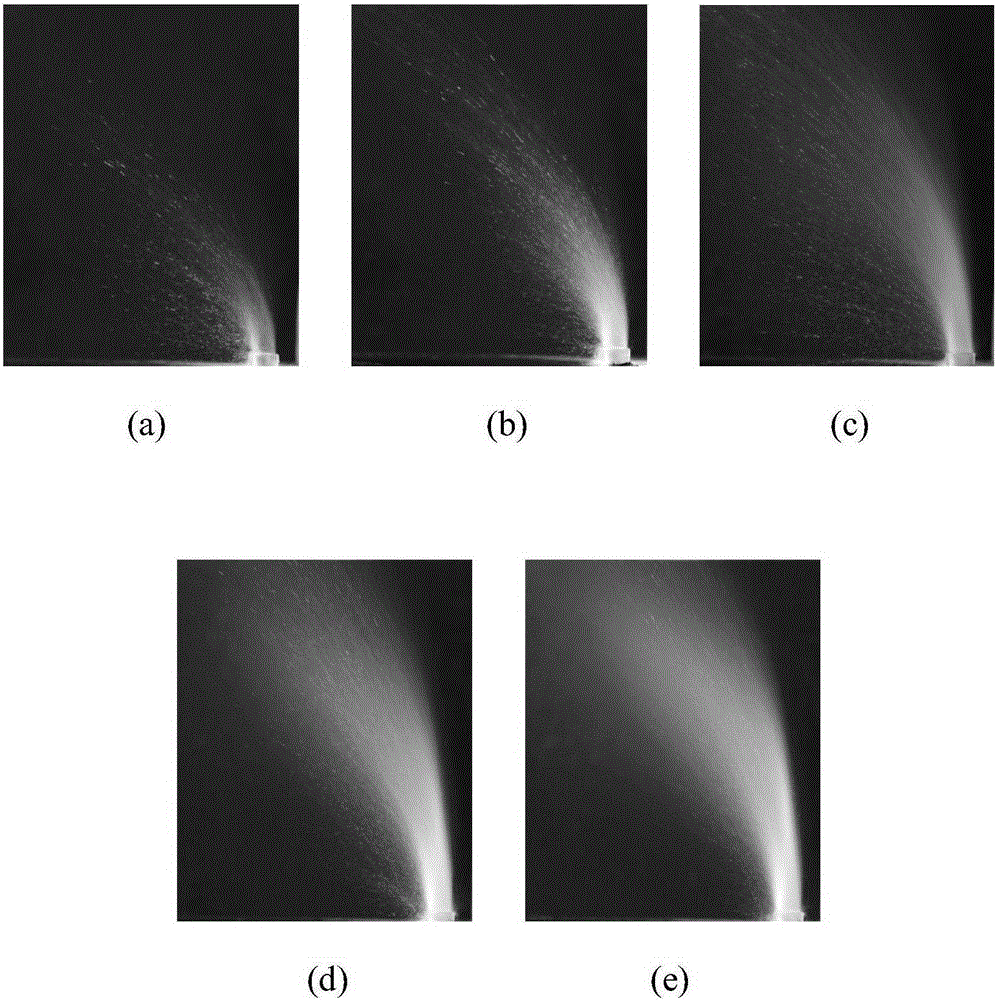

[0043] The inner cavity of the mainstream pipeline is a rectangular cavity with a cross-sectional size of 180×180mm. The mainstream gas is provided by an air compressor, and the velocity range in the experiment is 2-14.5m / s. The inner diameter of the annular flow jet tube is 10mm, and the length is 1.5m. The gas and liquid enter the annular flow through the gas-liquid mixer (the annular flow generator, the structure is a honeycomb with small holes on the wall, and the diameter of the small holes is 200um). The jet tube forms a gas-liquid two-phase annular flow jet. Among them, the gas flow rate range is 5.65-19.78m 3 / h (the equivalent superficial gas velocity range is about 20-70m / s), and the liquid working medium flow rate range is 14-114kg / h (the equivalent superficial liquid velocity range is about 7-12.7m / s). The camera is used to photograph the jet atomization process and atomization structure, and the Malvern particle size analyzer is used to measure the particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com