Braking spiral paint spraying equipment

A painting equipment, spiral technology, applied in the field of braking spiral painting equipment, to achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below.

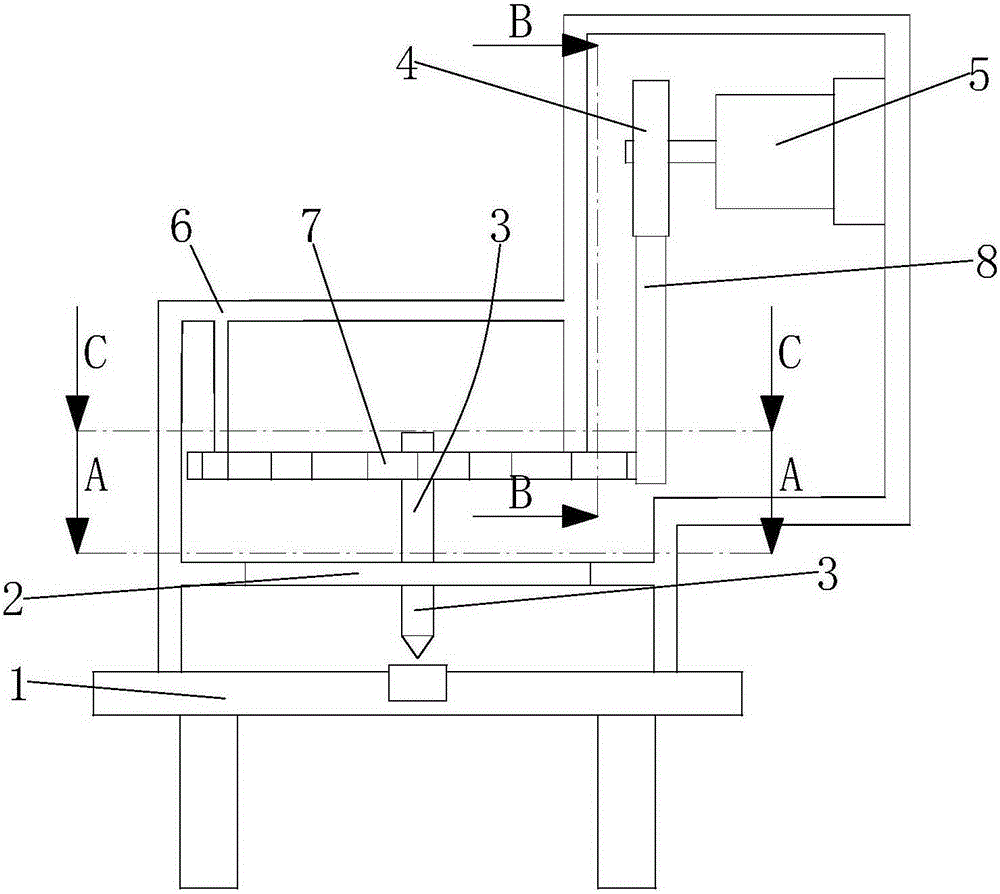

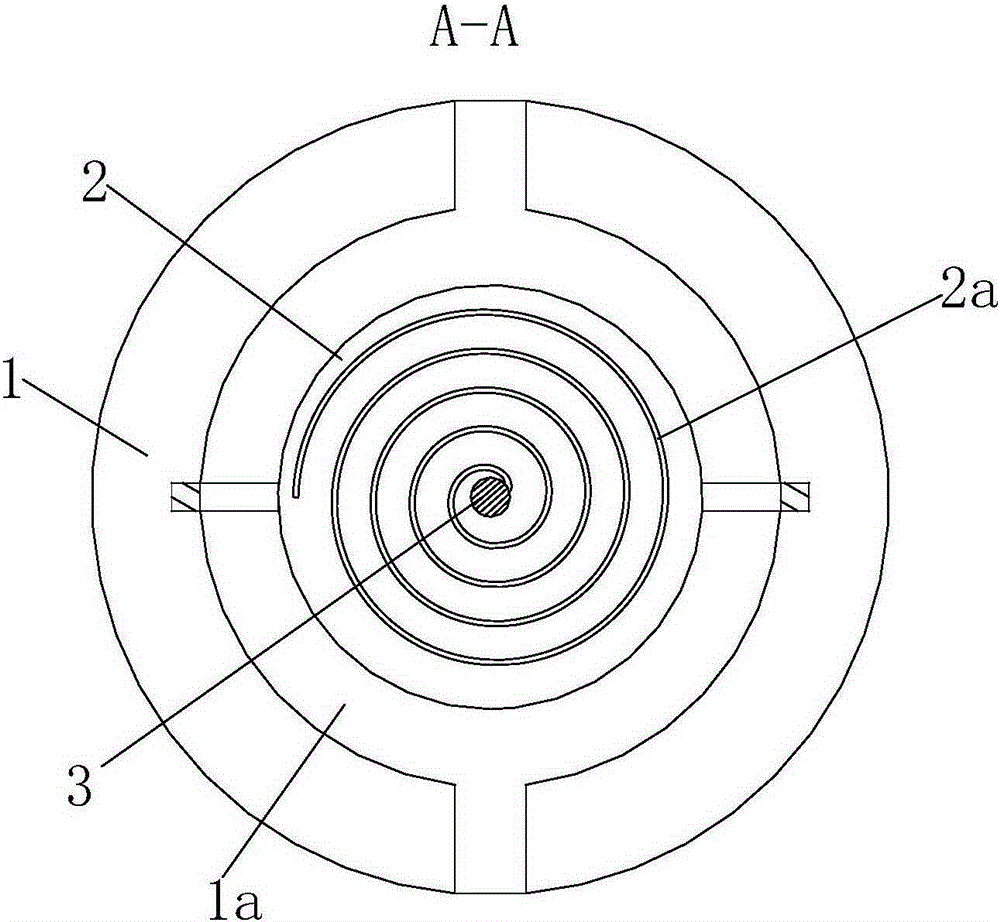

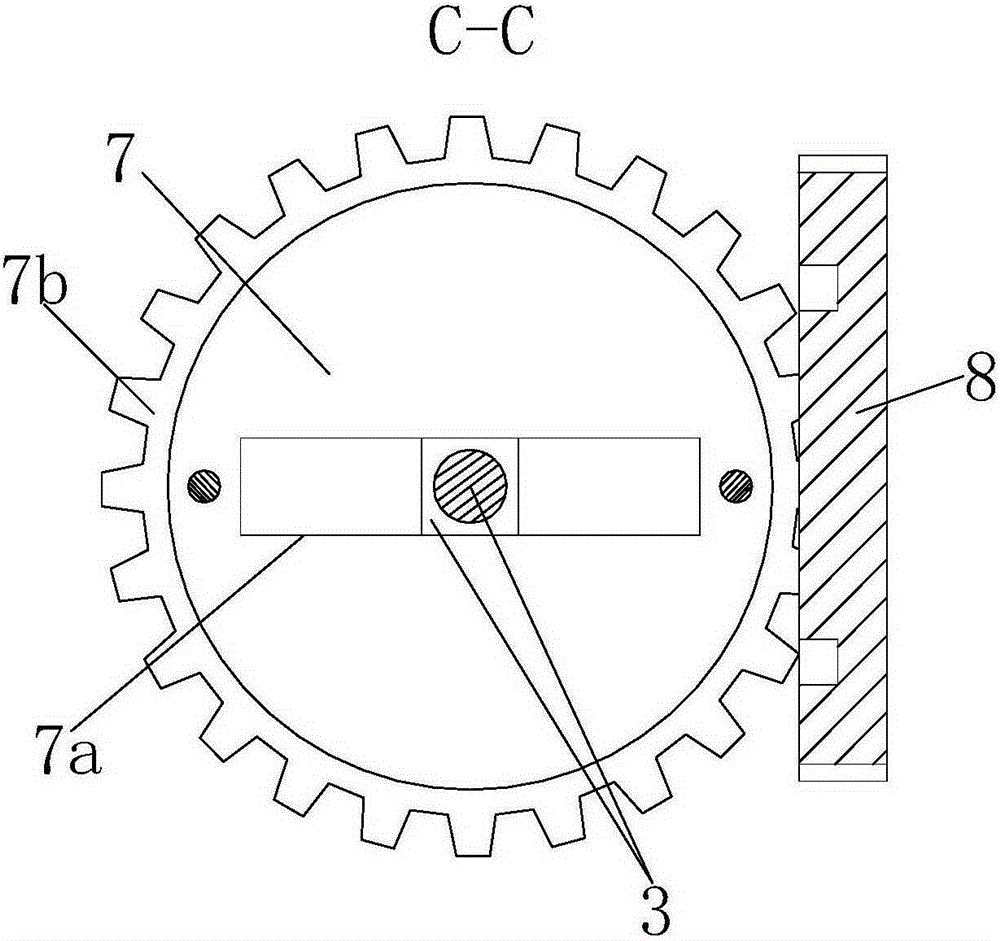

[0020] like Figure 1 to Figure 4 As shown, a braking spiral paint spraying equipment mainly includes a workbench 1, and a placement groove 1a is provided in the center of the workbench 1, and a circular No. 1 control frame 2 is provided at the upper end of the placement groove 1a. The No. 1 control rack 2 is provided with a No. 1 spiral groove 2a, and the No. 1 control rack 2 is provided with a No. 2 control rack 7 directly above the No. 2 control rack 7. In the rectangular groove 7a of the center of mass, a spray gun 3 is slidably installed in the rectangular groove 7a along the length direction, and the lower end of the spray gun 3 extends through the No. 1 spiral groove 2a.

[0021] The outer arc end surface of the No. 2 control frame 7 is provided with a No. 1 spur gear 7b, the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com