Packaging material processing system and packaging material processing technology

A packaging material and processing system technology, which is applied in the field of packaging material processing system and its processing technology, can solve the problems of slow production speed, poor printing effect, difficult operation, etc., and achieve the goal of improving yield rate, shortening processing cycle, and reducing production difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

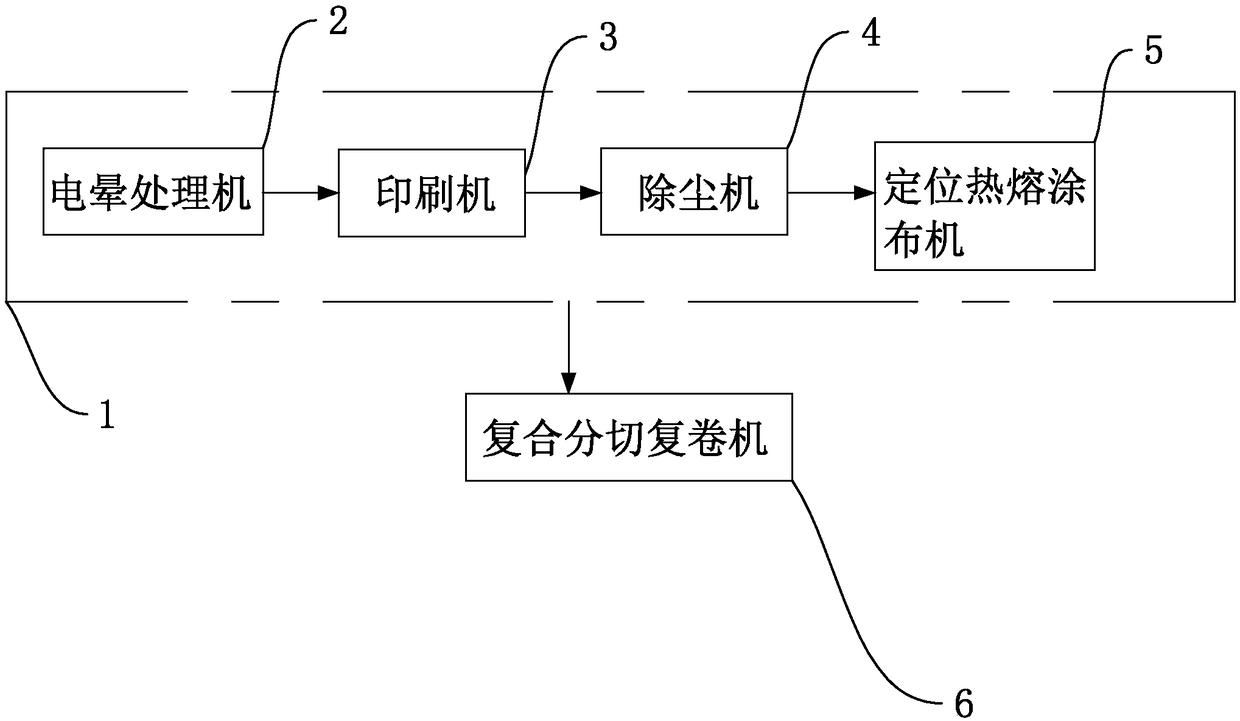

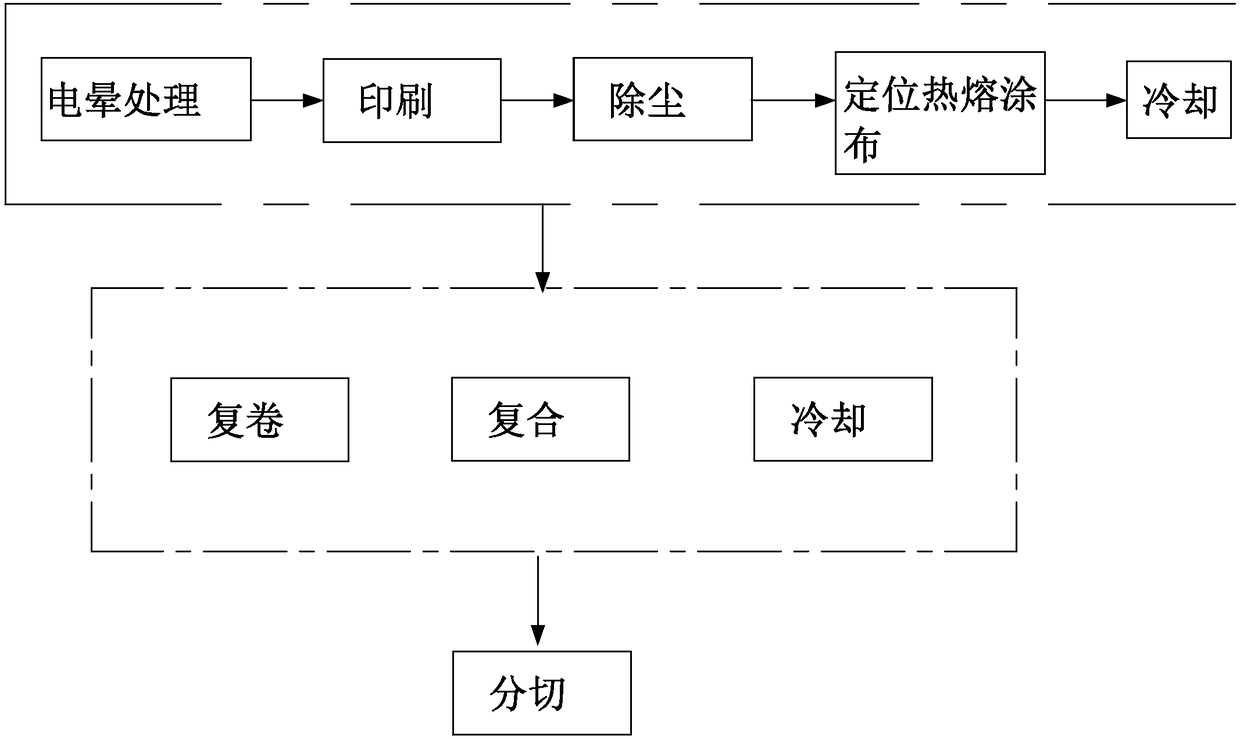

[0027] Embodiment 1: a kind of packaging material processing system, such as figure 1 and figure 2 As shown, as a brand-new printing positioning hot-melt coating, recombined printing and packaging technology production process improvement. At the same time, the positioning hot-melt coating is advanced to the printing process, which reduces the subsequent overprint positioning hot-melt coating equipment, which reduces the difficulty of production and reduces the process. It mainly includes the hot-melt system 1, which includes electric Corona treatment machine 2, printing machine 3 is connected to corona treatment machine 2, dust collector 4 is connected to printing machine 3, and positioning hot melt coating machine 5 is also connected to dust collector 4, and positioning hot melt coating machine 5 is positioned at the same time A composite roller is arranged on the top, and a rubber roller is pasted on the surface of the composite roller. Thus, the process of printing whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com