Air blower for simulating automobile operating environment

A technology of operating environment and blower, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of cumbersome pipeline laying, difficult control of wind speed and direction of the wind, and high cost, so as to achieve convenient air exhaust performance and convenience Testing, Facilitating Assembly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

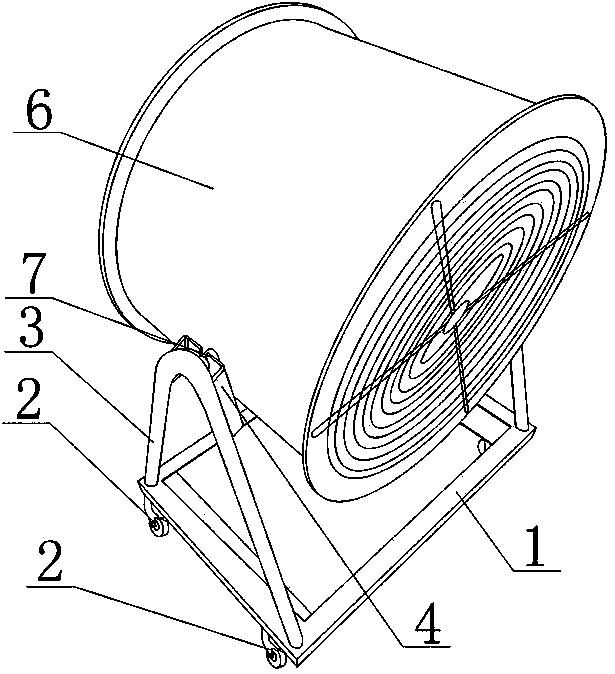

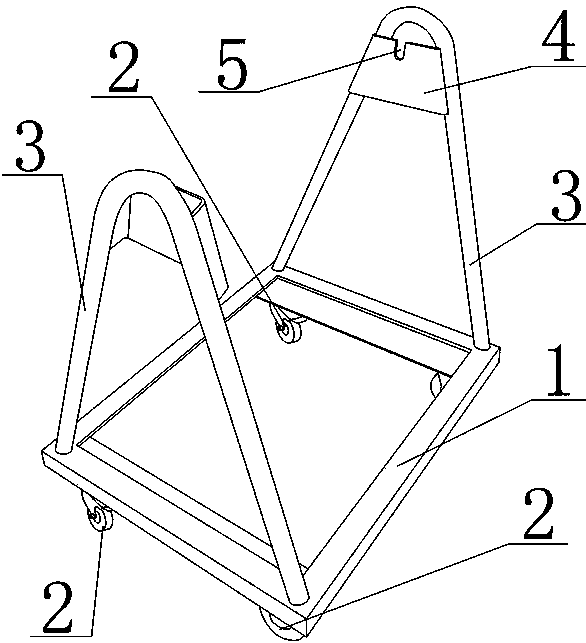

[0020] Such as Figures 1 to 2 As shown, the air blower for simulating the running environment of automobiles in the present invention includes a whole flat frame 1 formed by connecting steel materials. , at least two adjacent wheels 2 in the four wheels 2 are universal wheels. Two mutually parallel supports 3 are installed on the frame 1, and the support 3 and the flat frame 1 are perpendicular to each other, and a hanging plate 4 is arranged on the two supports 3, and the two hanging plates 4 are parallel and opposite to each other, and the two sides of the hanging plate 4 A bending part is provided, and the hanging plate 4 is connected with the bracket 3 through the bending part; hanging holes 5 are provided on the two hanging plates 4, and two hanging rods 7 are installed on the side of the fan body 6, and the two hanging rods 7 are respectively matched with the hanging holes 5, and the hanging rod 5 is inserted into the two hanging holes 5 to form a structure with the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com