Circuit mechanical shock test fixing device

A mechanical impact and fixing device technology, applied in impact testing, measuring devices, workpiece clamping devices, etc., can solve the problems of difficult fixing, uneven force on microcircuits, and the substrate of microcircuits is easily damaged, and achieves enhanced universality. Adaptability, elimination of adverse effects, objective and accurate impact test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

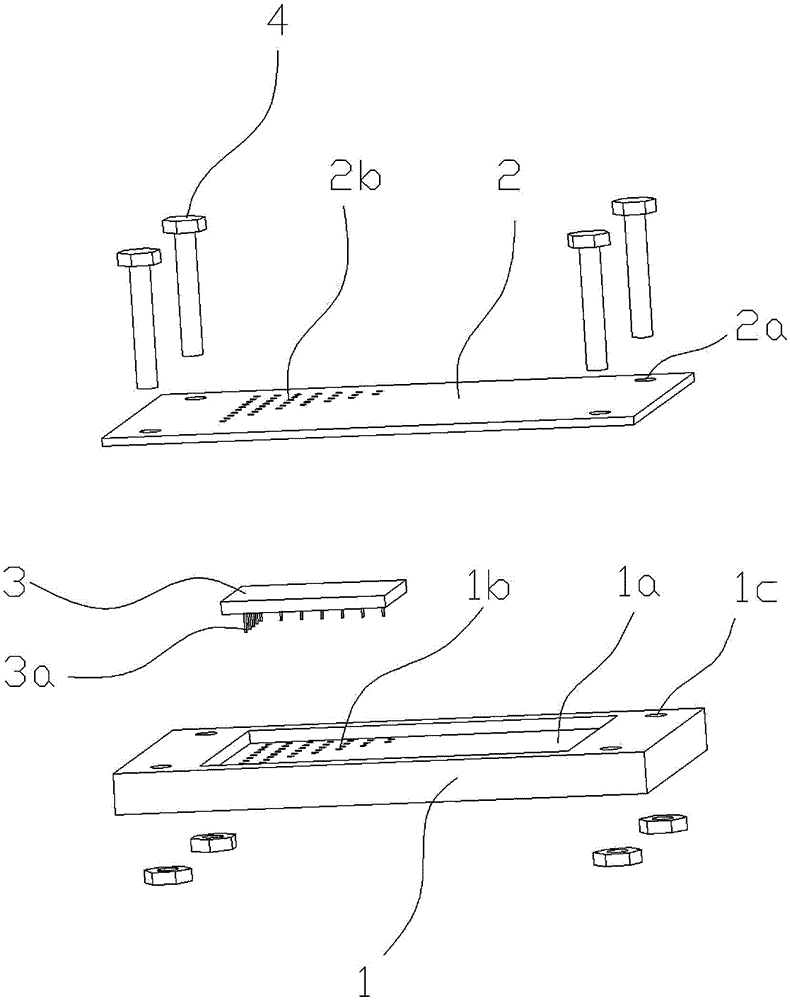

[0024] Such as figure 1 As shown, the circuit mechanical shock test fixture provided by the present invention is characterized in that: it includes a support plate 1 and a pressure plate 2, and the support plate 1 and the pressure plate 2 are cuboid plates with relatively good rigidity. A rectangular groove 1a is provided on the upper side of the groove 1a, and the lower pin insertion holes 1b are arrayed in the groove 1a, and four lower installation through holes 1c are uniformly distributed at the four corners of the support plate 1, and the pressure plate 2 There are upper pin jacks 2b on the top, and the upper pin jacks 2b cooperate with the lower pin jacks 1b of the support plate 1 one by one, and the upper pin jacks 2b and the lower pin jacks 1b are equal The holes are arrayed at a pitch of 2.54mm. Four upper mounting through holes 2a are evenly distributed at the four corners of the pressure plate 2, and the upper mounting through holes 2a and the lower mounting through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com