Low-noise submarine

A low-noise, submarine technology, applied in the direction of ships, underwater ships, special-purpose ships, etc., can solve the problems of complex sound insulation, sound absorption or sound reduction structure, inability to achieve submarine sound reduction, poor noise reduction effect, etc., and achieve sound insulation effect. Excellent, easy-to-implement, zero-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

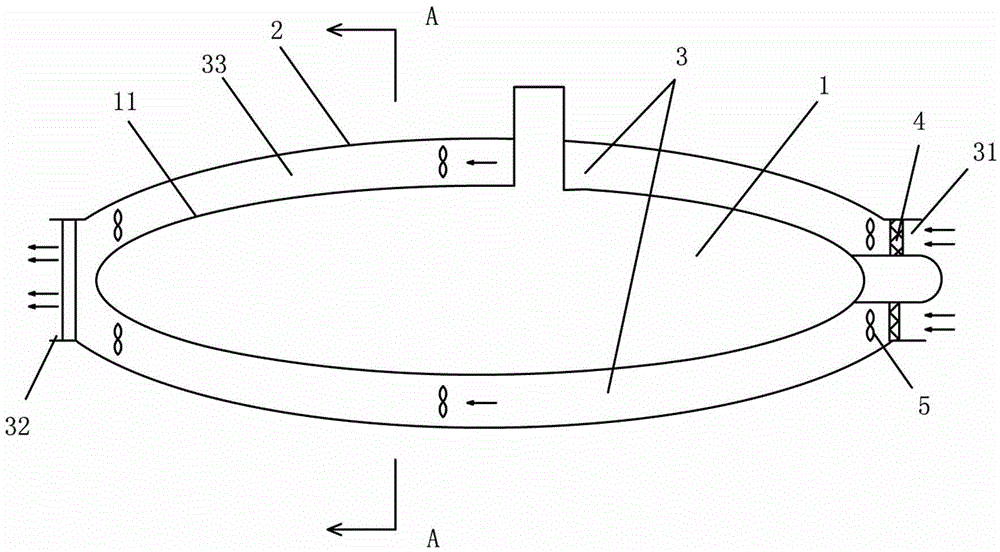

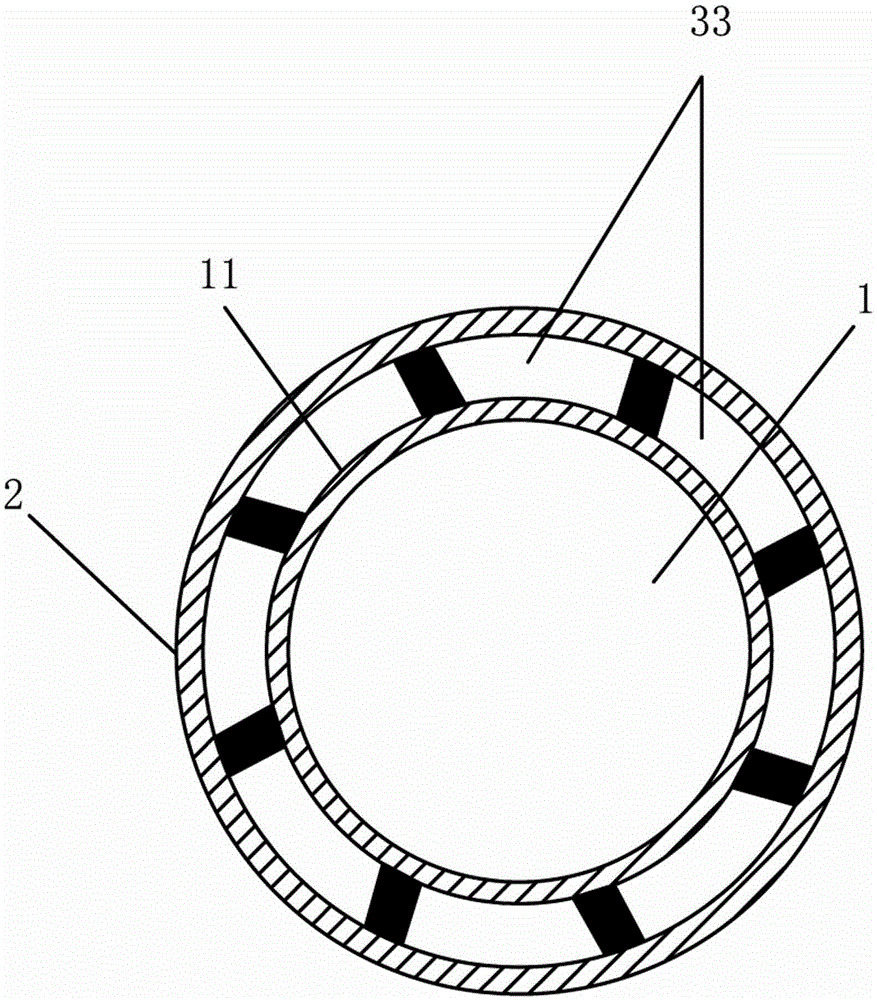

[0024] Embodiment one: if figure 1 and figure 2 As shown, a low-noise submarine includes a hull 1, and is characterized in that it also includes a sound-reducing shell 2, which is arranged on the outer wall 11 of the hull 1, and the distance between the hull 1 and the sound-falling shell 2 is There is a sound-reducing gap 3 between them, the sound-reducing gap 3 is liquid flowing through the gap 33, and the liquid flowing through the gap 33 is a channel for sea water to flow through. Water port and 31 rear discharge ports 32 are arranged on the front end and the rear end of the hull 1 respectively.

[0025] In order to prevent impurities in the seawater from being introduced, a filter 4 is provided at the front water inlet 31 where the liquid flows through the gap 33 .

[0026] In order to further improve the flow of seawater in the soundproof gap 3, and even significantly reduce the water resistance, the liquid flows through the gap 33 and is provided with a drainage prope...

Embodiment 2

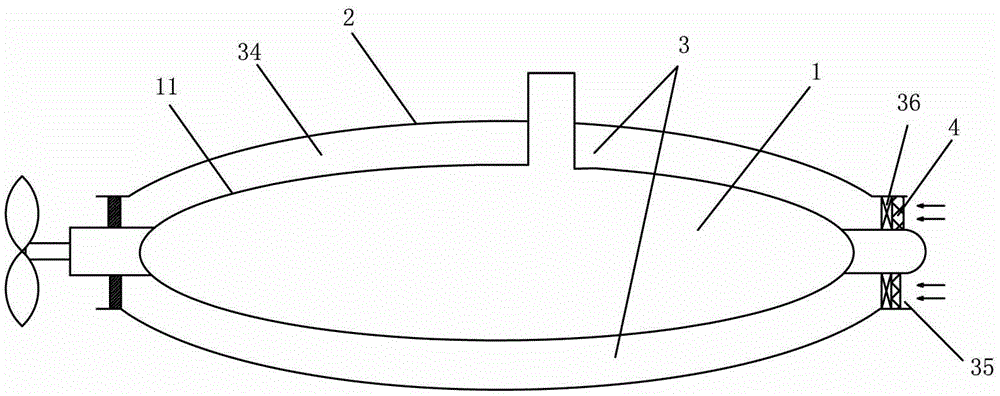

[0029] Embodiment two: if image 3 As shown, this embodiment is similar to the first embodiment above, the difference is: the liquid storage gap 34 can be a seawater storage airtight chamber, the seawater storage airtight chamber has a water exchange port 35, and the water exchange port 35 is provided with a water exchange valve 36 Similarly, in order to prevent the impurity in the seawater from entering, the water exchange port 35 of the seawater storage airtight chamber is provided with a filter screen 4; After the seawater is released, close the water exchange valve 35, and the seawater is used as a sound insulation material; otherwise, when the submarine stops running, the seawater in the liquid storage gap 35 can be discharged through the water exchange valve 35; pusher propeller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com