Electric slitting machine

An electric and coupling technology, applied in the direction of hoisting device, hoisting device, etc., can solve the problems of complex assembly process, high production cost, inconvenient to carry, etc., and achieve the effect of avoiding separation from the screw, low production cost and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

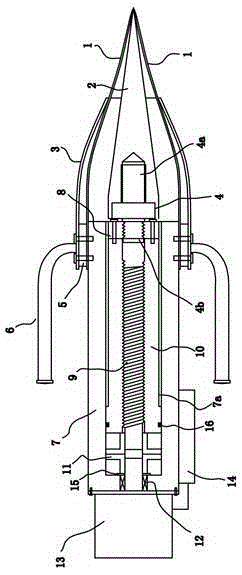

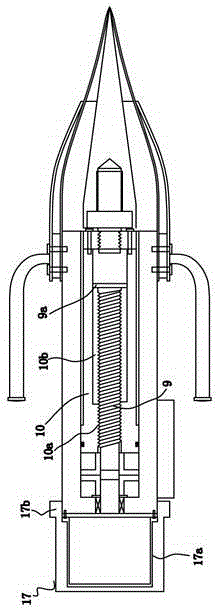

[0020] Such as figure 1 An embodiment of an electric slotter of the present invention is shown, including a spring plate 1, a wedge block 2, a spring plate holster 3, a stud bolt 4, a handle ring 5, a handle 6, a main housing 7, and a connecting nut 8. Screw rod 9, screw sleeve 10, coupling 11, bearing 12, micro motor 13 and rechargeable battery 14, the main housing 7 is provided with a hollow chamber 7a, the front end of the hollow chamber 7a is open and the rear end is closed; the spring plate 1. Wedge block 2, spring plate holster 3 and handle ring 5 are installed on the front end of main housing 7, wedge block 2 is set inside spring plate 1, spring plate holster 3 is set outside spring plate 1, handle 6 is welded and fixed On the handle ring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com