A kind of environment-friendly spraying type fire extinguishing material and preparation method thereof

A kind of fire extinguishing material, environmental protection technology, applied in the direction of fire retardant coatings, coatings, etc., can solve the problems of reduced fire extinguishing efficiency, pollution of the surrounding environment, easy occurrence of reburning, etc. The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the environmental protection spray type fire extinguishing material of the present invention comprises the steps:

[0044] 1. Preparation of A component

[0045] a1: Weigh the corresponding raw materials according to the above ratio for use;

[0046] b1: Add acrylate monomer liquid, ammonium polyphosphate, white carbon black, ammonium phosphate salt and oxidant into the container with disperser under normal temperature and pressure;

[0047] c1: Turn on the disperser to stir, the stirring speed is 900-1200 rpm, and the stirring time is 40-60 minutes;

[0048] d1: Fill the mixture after stirring to get A component;

[0049] 2. Preparation of B component

[0050] a2: Weigh the corresponding raw materials according to the above-mentioned ratio for later use;

[0051] b2: Add acrylate monomer liquid, ammonium polyphosphate, ammonium phosphate salt, metal hydroxide and reducing agent into the container with disperser under normal temperature and...

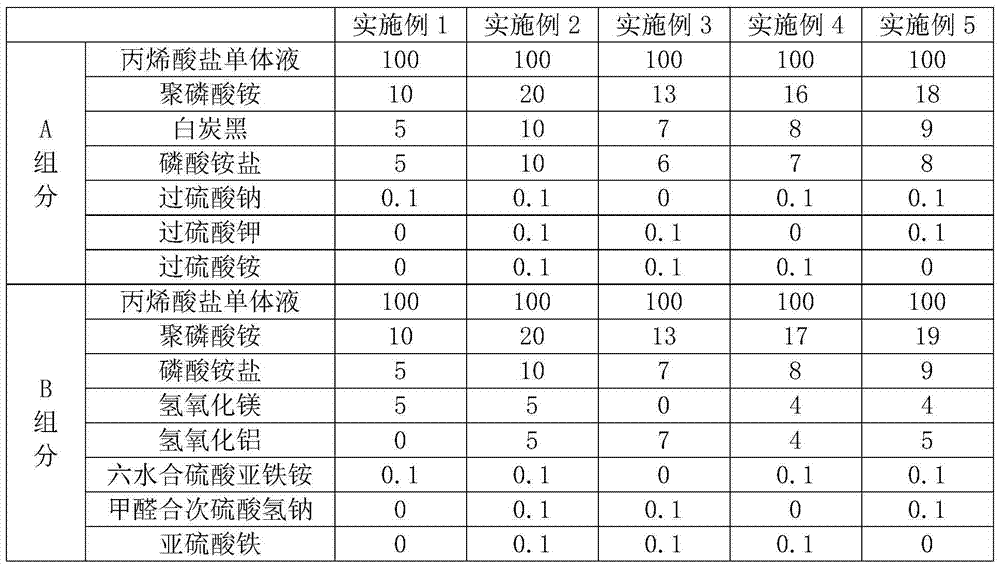

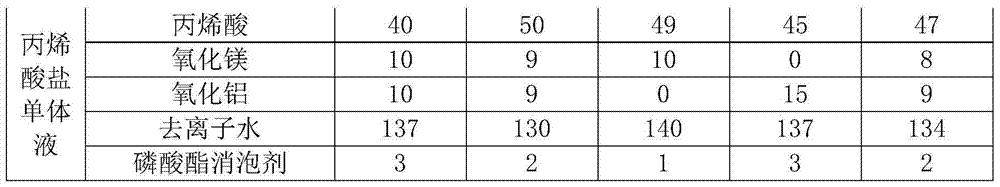

Embodiment 1

[0063] The environmental protection spraying type fire extinguishing material of the present invention comprises A component and B component, and A component comprises acrylate monomer liquid, ammonium polyphosphate, white carbon black, ammonium phosphate, sodium persulfate, and the content of the above components is expressed in parts by mass The calculations are respectively: 100 parts of acrylate monomer liquid, 10 parts of ammonium polyphosphate, 5 parts of white carbon black, 5 parts of ammonium phosphate salt, and 0.1 part of sodium persulfate. Component B includes acrylate monomer liquid, ammonium polyphosphate, ammonium phosphate salt, magnesium hydroxide, and ferrous ammonium sulfate hexahydrate. The contents of the above components are calculated in parts by mass: 100 parts of acrylate monomer liquid, 10 parts of ammonium, 5 parts of ammonium phosphate, 5 parts of magnesium hydroxide, 0.1 part of ferrous ammonium sulfate hexahydrate.

[0064] In the environment-frien...

Embodiment 2

[0084] The environmental protection spraying type fire extinguishing material of the present invention comprises A component and B component, and A component comprises acrylate monomer liquid, ammonium polyphosphate, white carbon black, ammonium phosphate salt, sodium persulfate, potassium persulfate, ammonium persulfate, The contents of the above components are calculated in parts by mass: 100 parts of acrylate monomer liquid, 20 parts of ammonium polyphosphate, 10 parts of white carbon black, 10 parts of ammonium phosphate salt, 0.1 part of sodium persulfate, 0.1 part of potassium persulfate, 0.1 parts of ammonium sulfate. Component B includes acrylate monomer liquid, ammonium polyphosphate, ammonium phosphate, magnesium hydroxide, aluminum hydroxide, ammonium ferrous sulfate hexahydrate, sodium formaldehyde sulfoxylate and ferric sulfite. The parts are: 100 parts of acrylate monomer liquid, 20 parts of ammonium polyphosphate, 10 parts of ammonium phosphate salt, 5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com