Pressure lubrication system for free piston internal combustion engine generator

A technology for internal combustion generators and lubrication systems, applied in free piston engines, engine lubrication, pressure lubrication of lubrication pumps, etc., to achieve high volume power, compact structure, and avoid severe wear of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

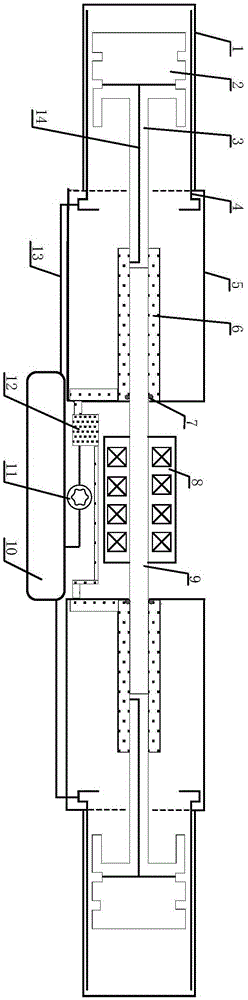

[0027] A pressure lubrication system for a free-piston internal combustion generator, such as figure 1 As shown, it mainly includes a free piston generator module, an oil tank 10 , an electric motor oil pump 11 , an oil filter 12 , an oil pipe 13 and a sealing ring 7 .

[0028] The free piston generator module mainly includes: cylinder 1, piston 2, connecting rod 3, cylinder liner 4, scavenging air box 5, linear motor stator coil 8 and motor mover 9.

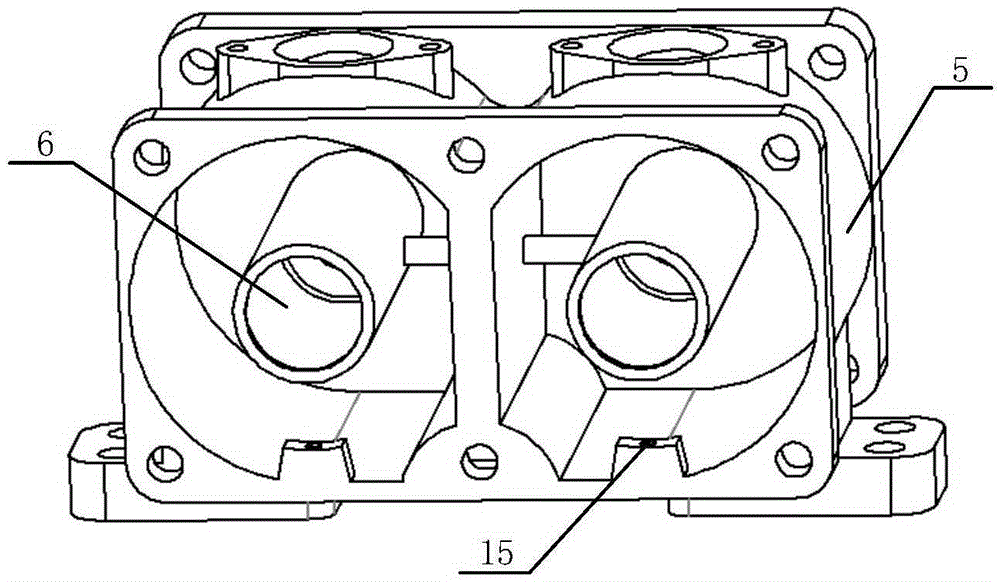

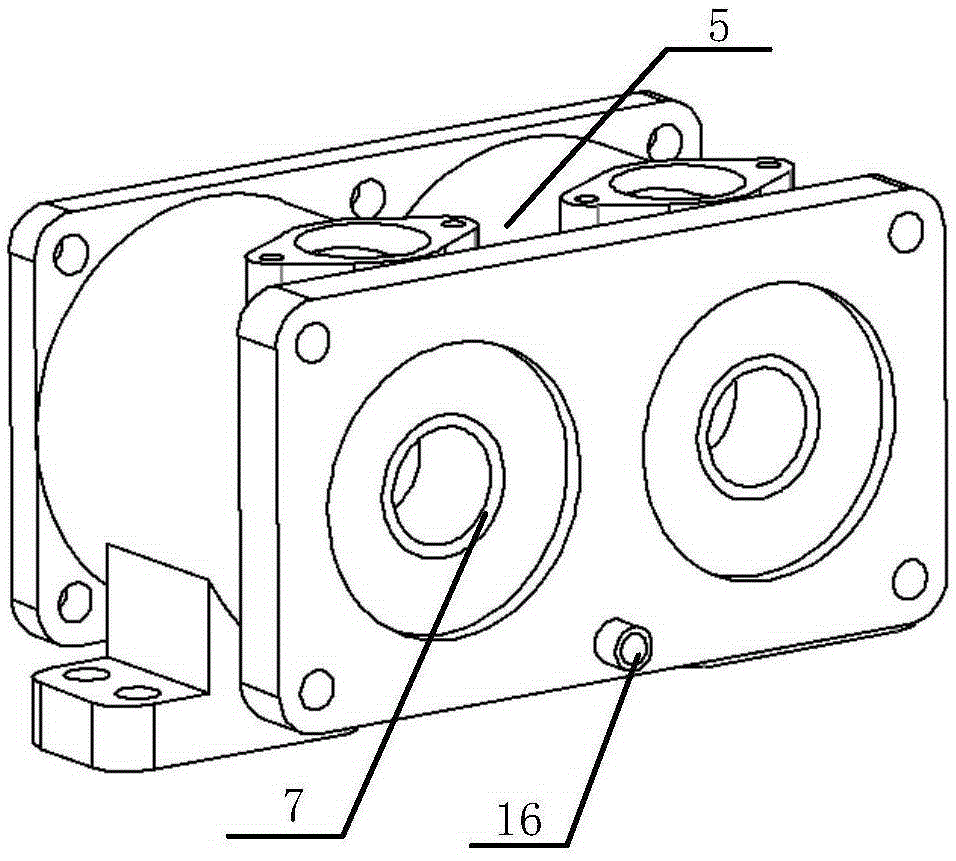

[0029] like figure 2 , image 3 As shown, a lubricating oil chamber 6 is placed at the inner center of the scavenging box 5; the lubricating oil chamber 6 is a hollow cylinder, and the connecting rod 3 and the motor mover 9 reciprocate in the lubricating oil chamber 6; the lubricating oil chamber 6 and the sweeping The side of the air box 5 close to the stator coil 8 of the linear motor is fixedly connected, and a sealing ring 7 is arranged at the connection. The sealing ring 7 scrapes off the lubricating oil attached to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com