Cylindrical roller bearing with inner ring punched into two columns

A cylindrical roller bearing and inner ring technology, applied in the field of bearing manufacturing, can solve the problems of increasing production costs, reducing bearing service life, affecting production systems, etc., and achieving the effects of increasing service life and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

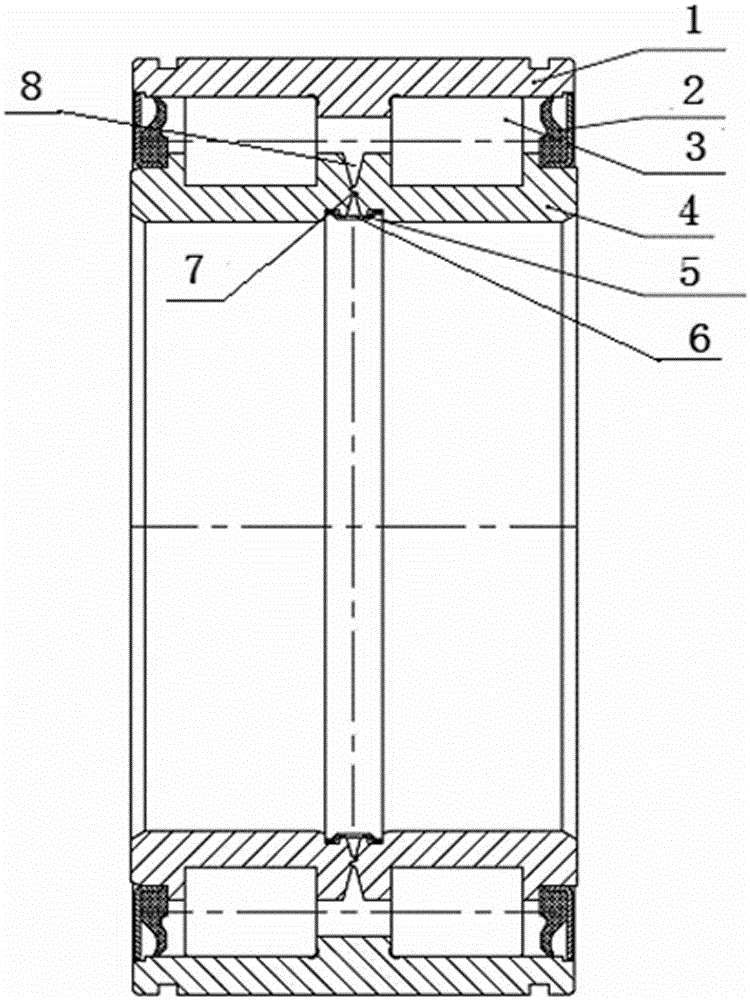

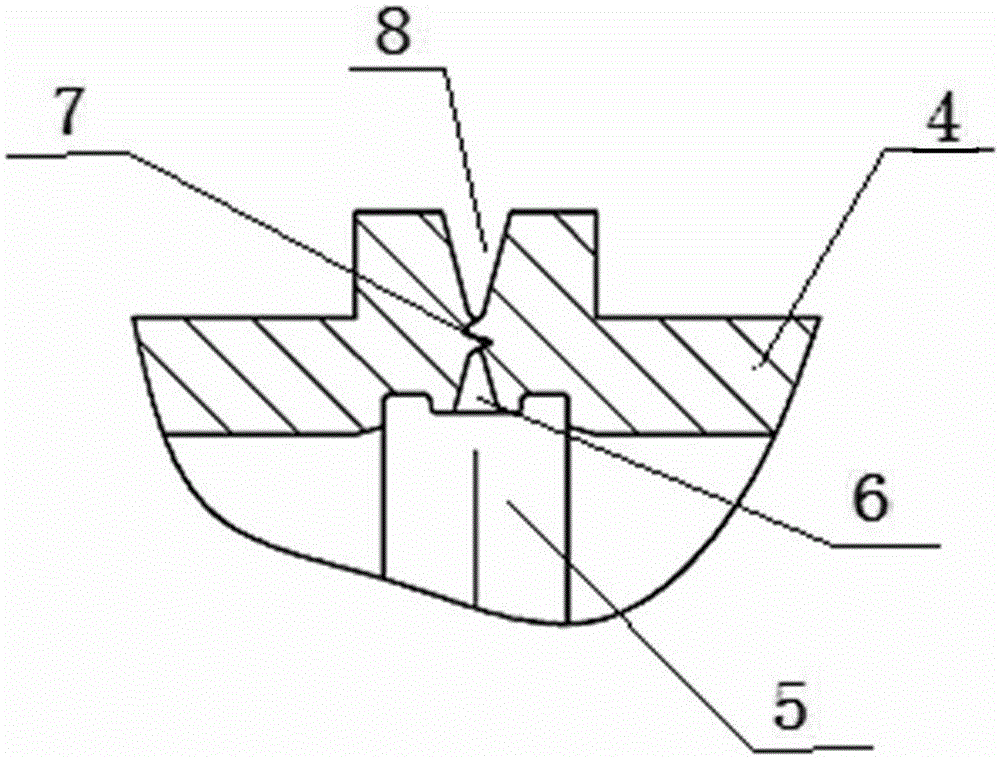

[0009] A double-row cylindrical roller bearing with an inner ring flush, comprising an outer ring 1, an inner ring 4, a cylindrical rolling body 3 installed between the outer ring and the inner ring, and a sealing ring assembly installed between the end faces of the outer and inner rings 2. Connect the connecting ring 5 which is divided into two independent inner rings. The inner ring is processed into an annular inner ring opening 7, and the inner and outer ends of the inner ring opening are respectively processed into opposite inner V-shaped annular notches 6 and outer V-shaped annular notches 8, through which the inner ring The punched part is connected to form the integral inner ring, and after the machining of the integral inner ring is completed, it is divided into two independent inner rings by mechanical method. When assembling the finished product, install the two inner rings along the irregular tooth-shaped seams at the cracks on the end faces to ensure the width and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com