Suspended flexible flywheel

A technology of energy storage flywheel and flywheel device, which is applied in the direction of flywheel, etc., and can solve the problems of deformation change, unfavorable high-speed dynamic balance correction, creep deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

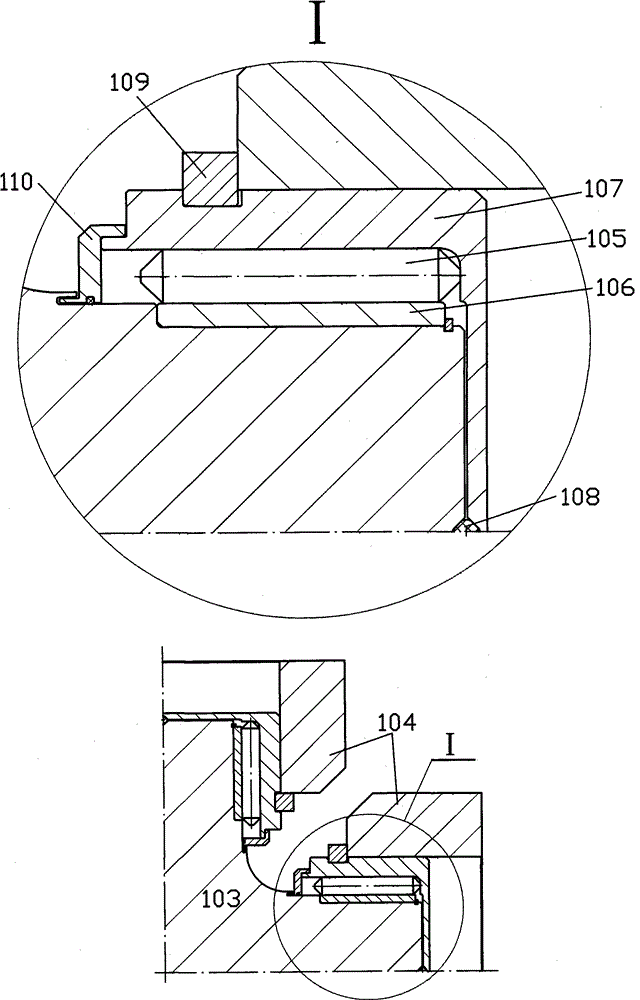

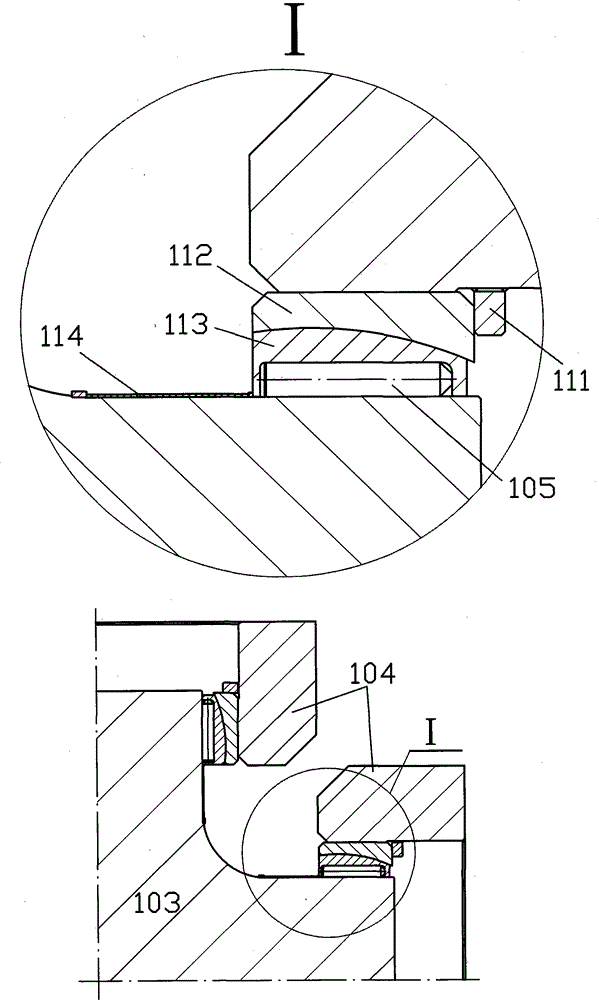

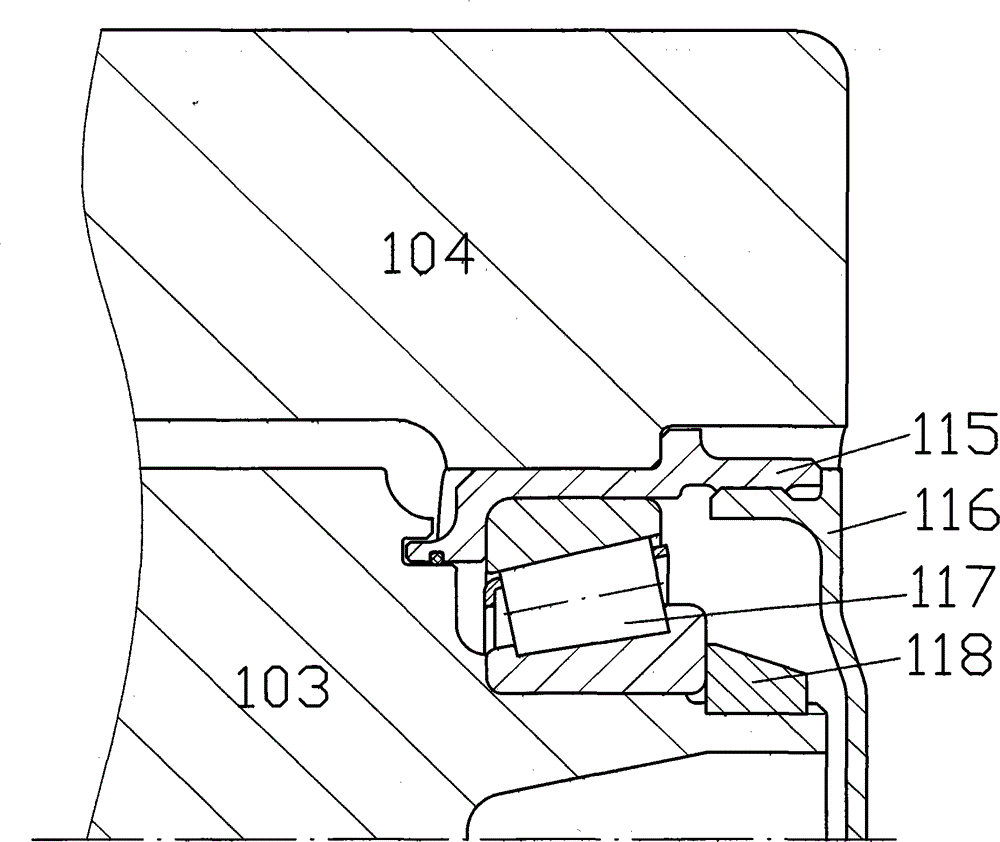

[0060] A specific implementation of a suspended flexible flywheel device for power grid peak regulation (Fig. 23) is as follows.

[0061] Main parameters: rated speed 1321.9r / min, rated transmission power 12.8MW, maximum transmission torque 277398Nm (at 1 / 3 rated speed and above, rated power 12.8MW can be transmitted), maximum outer diameter of flywheel 9648mm, maximum outer diameter of device 10697mm, the total height of the device is 15894mm, the total weight of the device is 1414587kg, the total weight of the rotor is 1181437kg, and the rated energy storage is 38465kWh.

[0062] The flywheel rotor has 15 sets of wheel bodies arranged in series up and down, and each set of wheel bodies has two mass blocks (53) and two supporting bodies (54) ( Figure 18 ), each set of wheel body is connected with a cylindrical central shaft (102), the upper and lower adjacent central shafts are connected by flanges and threaded fasteners, the 14 central shafts located below have the same str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com