A positioning sleeve

A technology of sleeves and floor slabs, applied in the field of clean room floor slabs, can solve problems affecting the anti-static performance of ventilation panels, damage to the surface coating of ventilation panels, uneven holes, etc., to ensure anti-static performance and stability , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

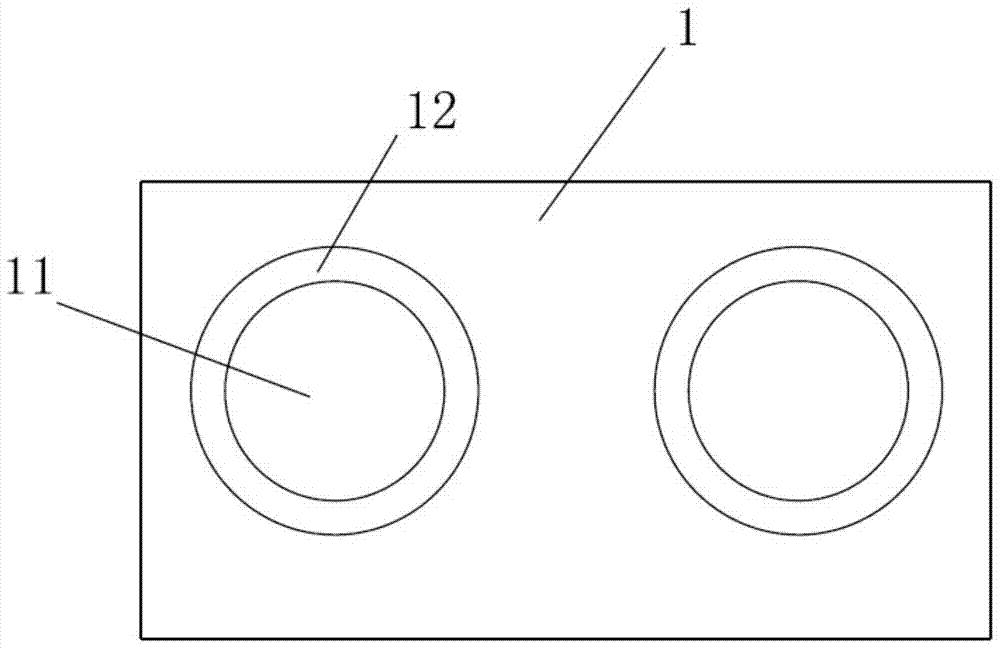

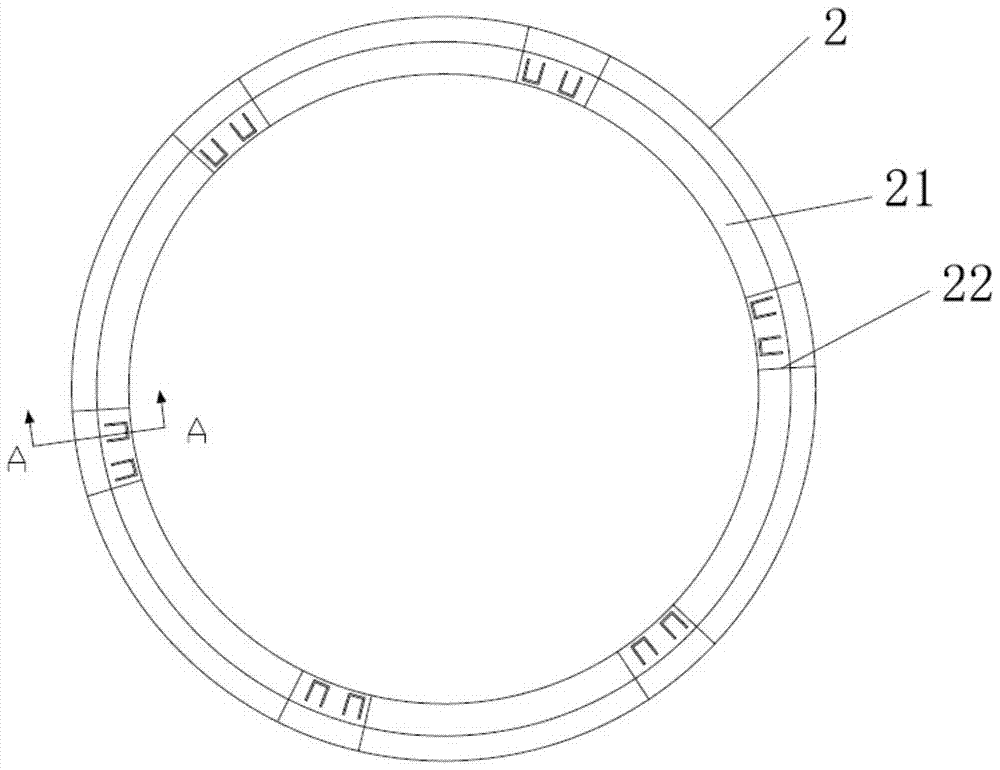

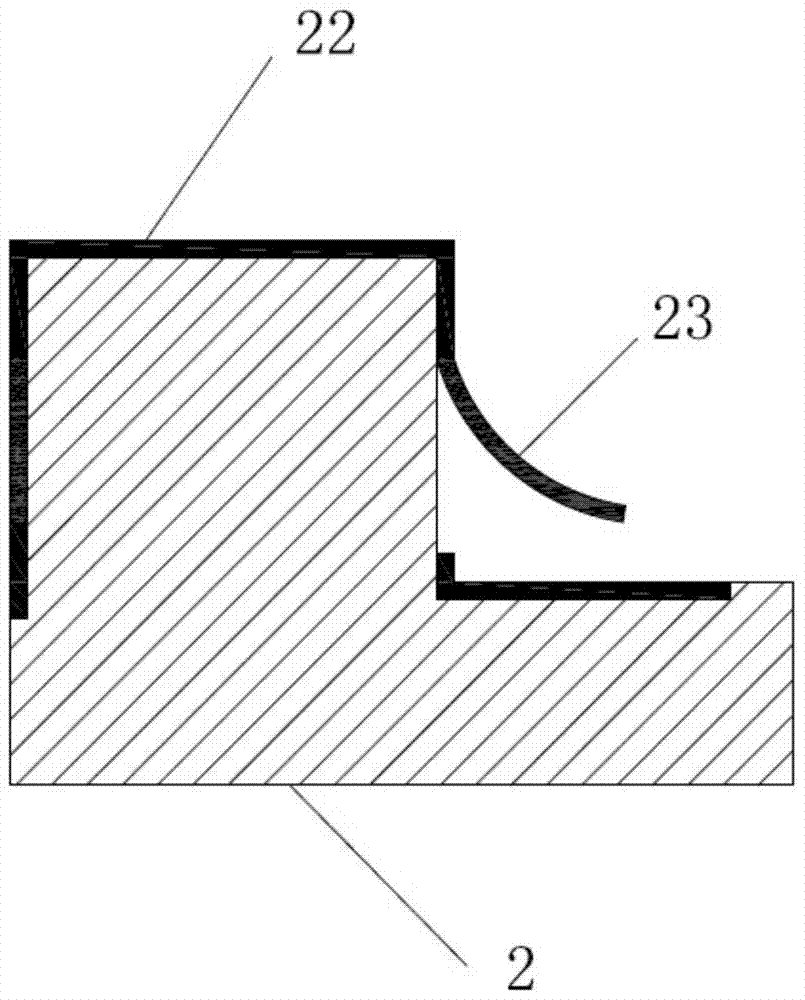

[0029] In the clean room, ventilation panels are installed on the multiple holes on the clean room floor slab constructed of waffle boards. The ventilation panels are elevated floors. To ensure that the clean air on the underside of the floor directly enters the clean room, so that the air inside and outside the clean room circulates. At present, in the process of floor slab production, there may be unevenness in the hole, and the ventilation panel often shakes after being covered on it, and the ventilation panel will collide with the floor when it is placed, which will cause the ventilation panel Damage to the surface coating will affect the anti-static performance of the ventilation panel.

[0030] Aiming at the deficiencies in the prior art, the present invention provides a positioning sleeve, which is arranged on the ventilation hole to carry the ventilation plate, and improves the stability of the ventilation plate after installation. Since the building structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com