A refraction-based solar homogeneous tube reactor or dryer

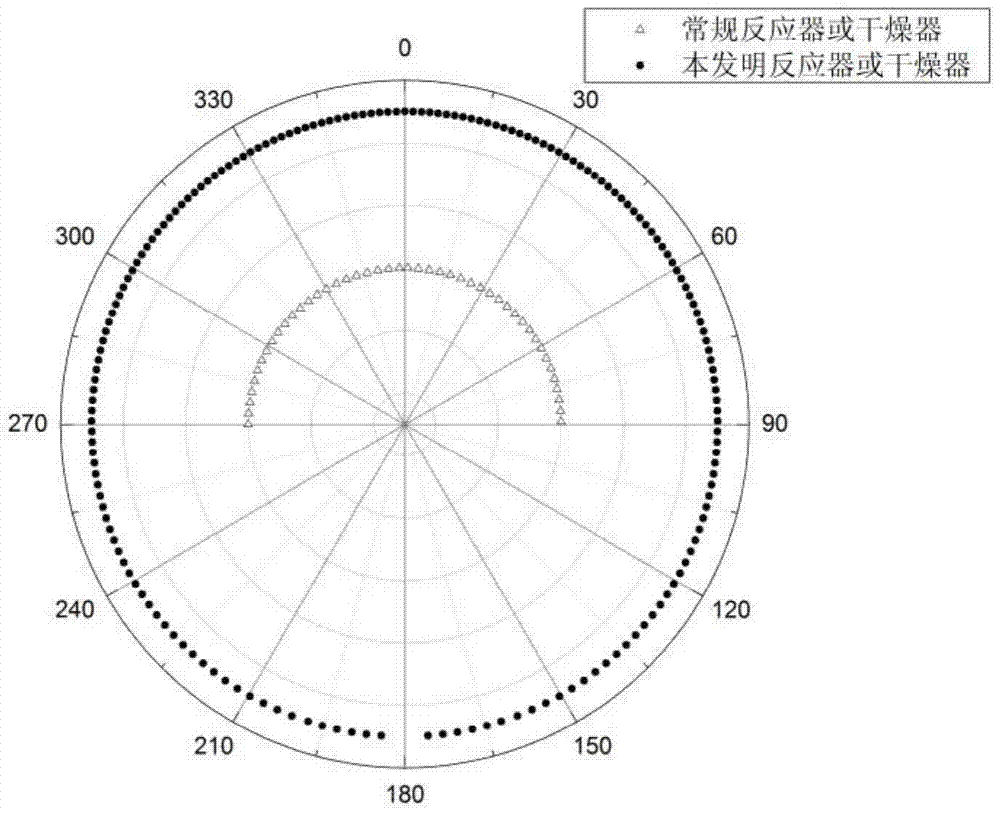

A solar energy and reactor technology, which is applied to solar thermal collectors, solar thermal collectors using working fluids, solar thermal storage, etc. The effect of light receiving angle, uniform circumferential distribution, and improved photothermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

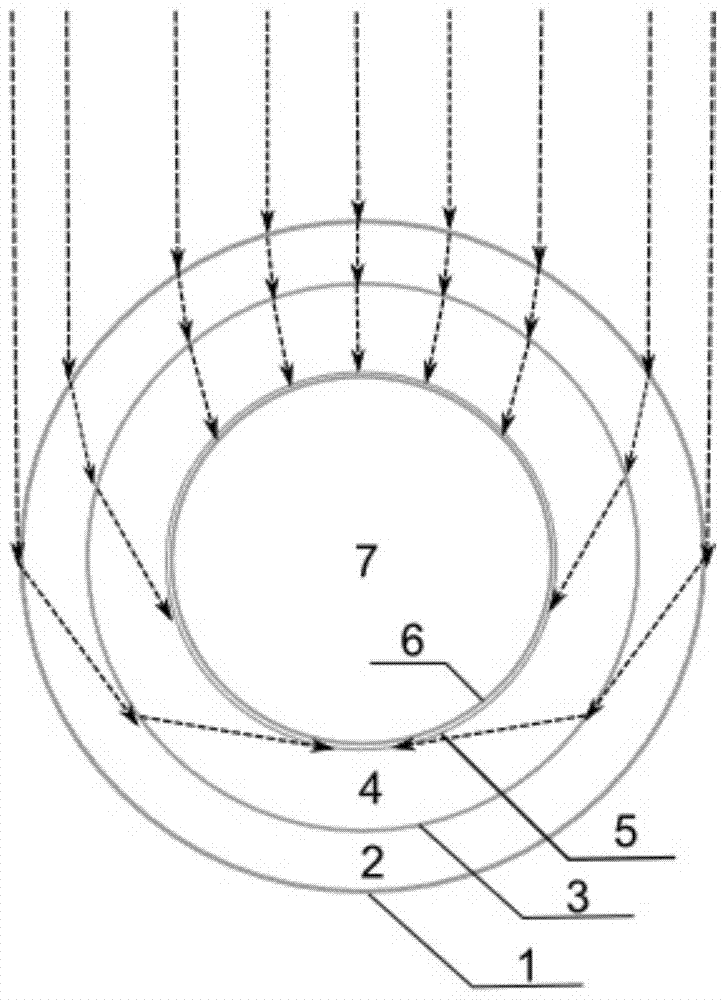

[0022] Such as figure 1 As shown, the present embodiment is based on a refraction-based solar homogeneous tube reactor or drier, from the outside to the inside from the outer layer anti-reflection film 1, the first layer of cylindrical transparent hollow light refraction medium 2, the middle layer anti-reflection film 3, The second layer of cylindrical transparent hollow light-refractive medium 4, the inner anti-reflection film 5, the inner wall 6 and the inner reaction or drying chamber 7 are composed. The thickness of each layer of anti-reflection coating is determined according to the target anti-reflection light and its thickness is extremely small, ignoring the influence of its thickness on light transmission.

[0023] As a preferred embodiment of the present invention, the first layer of cylindrical transparent hollow light ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com