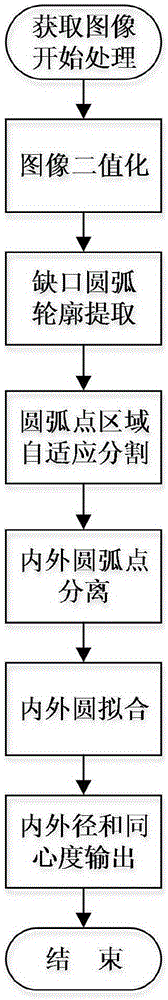

Notch circular arc part dimension visual detection method based on self-adapting region division

A technology of area segmentation and visual inspection, applied in the computer field, can solve the problem of poor applicability and achieve the effect of accurate industrial production inspection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

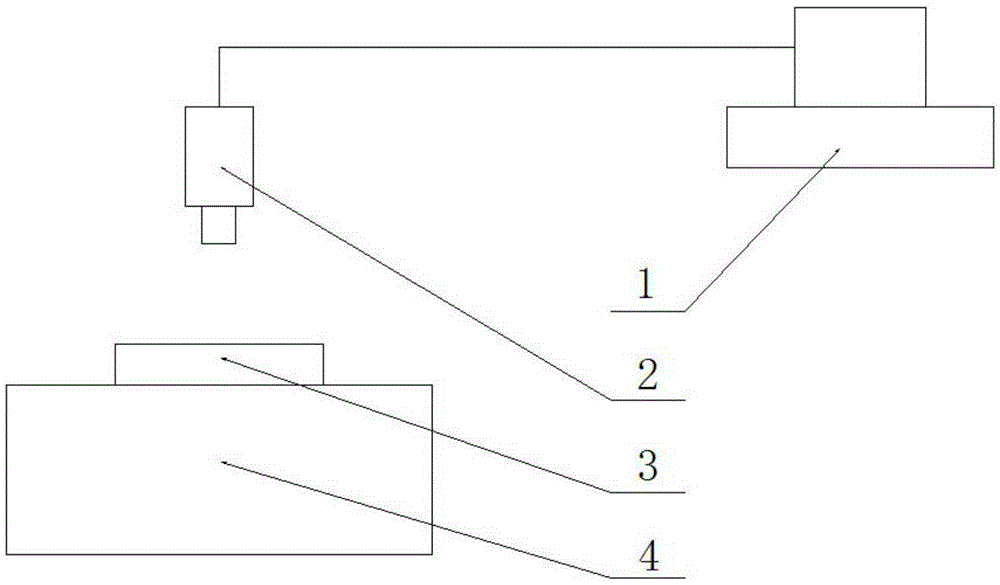

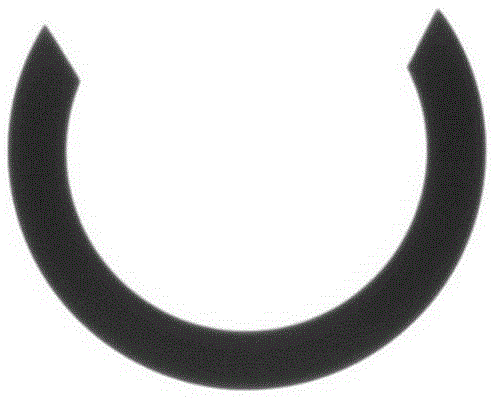

[0029] A method for visual detection of the size of a notch arc part based on adaptive area segmentation, the method illuminates the outline of the measured notch arc part 3 through a light source light box 4; an industrial camera 2 shoots the illuminated notch arc part, It is ensured that the part is completely presented in the image collected by the industrial camera; the image data is transmitted to the computer 1 through the data line, the self-developed software is run on the computer, and the image processing algorithm provided by the present invention is used to complete the accurate extraction of the inner and outer arc points, and Perform circle fitting on the extracted inner and outer arc points respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com