Surface acoustic wave filter encapsulation structure and manufacturing method

A packaging structure, surface acoustic wave technology, applied in electrical components, impedance networks, etc., can solve problems such as functional failure, and achieve the effects of low cost, simple and easy-to-control storage methods, and easy-to-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

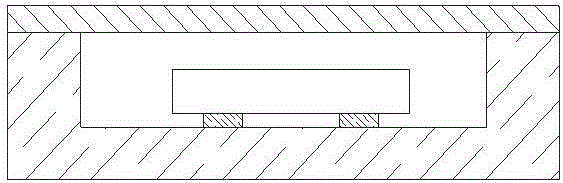

[0039] like image 3 As shown, a surface acoustic wave filter packaging structure in this embodiment includes a substrate 1, a groove 8 is provided on the front of the substrate 1, a pad 2 is provided in the groove 8, and a pad 2 is provided in the pad 2 is flip-mounted with a filter chip 3 through a conductive bump 4, and a layer of molding compound 6 is provided on the front of the substrate 1, and a protective cavity is formed between the molding compound 6 and the groove 8, and the molding compound 6 and the filter The chip functional area 3a of the chip 3 is not in contact.

[0040] The molding compound 6 is a thermosetting material, which is powder at room temperature and liquid at the melting point. The molding compound is filled to a certain height in the groove of the substrate under high temperature and then thermosets.

[0041] Its manufacturing method is as follows:

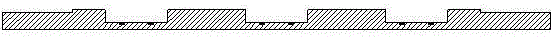

[0042] Step 1: See Figure 2a , providing a substrate with grooves on the front side;

[0043]...

Embodiment 2

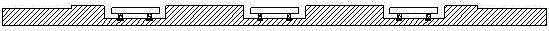

[0047] like Figure 4 As shown, a surface acoustic wave filter packaging structure in this embodiment includes a substrate 1, a groove 8 is provided on the front of the substrate 1, a pad 2 is provided in the groove 8, and the pad 2. The inner area is equipped with a filter chip 3 through conductive or non-conductive glue. The front side of the filter chip 3 is connected to the pad 2 through a metal wire. A layer of plastic sealing compound 6 is provided on the front side of the substrate 1. A protective cavity is formed between the grooves 8 , and the molding compound 6 is not in contact with the chip function area 3 a of the filter chip 3 .

Embodiment 3

[0049] like Figure 5 As shown, the difference between embodiment 3 and embodiment 1 is that the filter chip 3 is a TSV filter chip, and the filter chip 3 is provided with through holes, and the cavity structure needs to be ensured on the front and back sides of the filter chip 3, and the plastic encapsulant 6 is not in contact with the chip function area 3a of the filter chip 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com